2

2

"Them that don't know him don't like him and them that do sometimes don't know how to take him, he ain't wrong he's just different and his pride won't let him do the things to make you think he's right" - Ed Bruce (via Waylon and WIllie)

Tip to shorten your link: see the `?` after 376240227543? Anything after the number can be deleted.

5

5

Our inability to change everything should not stop us from changing what we can.

2

2

Robert Ray wrote:We make control cable for older car and truck heater controls, small engine cables all the time. If you can imagine the diameter of what that would be it's about.055 of an inch. Amazon for under 20.00 for a 1 pound roll. I have used smaller diameter piano wire for snares.

"Them that don't know him don't like him and them that do sometimes don't know how to take him, he ain't wrong he's just different and his pride won't let him do the things to make you think he's right" - Ed Bruce (via Waylon and WIllie)

6

6

Our inability to change everything should not stop us from changing what we can.

9

9

"Ah, but a man's reach should exceed his grasp,

Or what's a heaven for?"

Andrea del Sarto by Robert Browning

4

4

Kevin Olson wrote:Be aware that piano wire is carbon steel. It has very high tensile strength (400ksi or so) due to the wire drawing process working out the lattice dislocations (imperfections, basically), but it is carbon steel. So, it will corrode, given the opportunity. Oiling/tinning before exposure to water and drying afterward may help.

We use music wire at work for high strength electrical jumper wires and as a support or armature for lower resistance conductors. We also use beryllium copper wire - kind of covers both bases at once; not as strong as music wire, but a better conductor. Some of our stocked wires are as fine as 0.010" diameter.

For small diameter wire (mending my wife's jewelry), I have used jump ring pliers from the craft section of a big box store. But, for sturdier wire, the orthodontic pliers would be a better match. There are also small wire benders available which can be clamped in a bench vise, with dowel pins and whatnot, around which the wire can be bent. May be worth a look, too. Hobby shops which cater to scale modelers and model railroad types are likely to have helpful tools for your project, or at least you can see what to duplicate DIY.

"Them that don't know him don't like him and them that do sometimes don't know how to take him, he ain't wrong he's just different and his pride won't let him do the things to make you think he's right" - Ed Bruce (via Waylon and WIllie)

2

2

'What we do now echoes in eternity.' Marcus Aurelius

How Permies Works Dr. Redhawk's Epic Soil Series

5

5

"Ah, but a man's reach should exceed his grasp,

Or what's a heaven for?"

Andrea del Sarto by Robert Browning

Kevin Olson wrote:Judson -

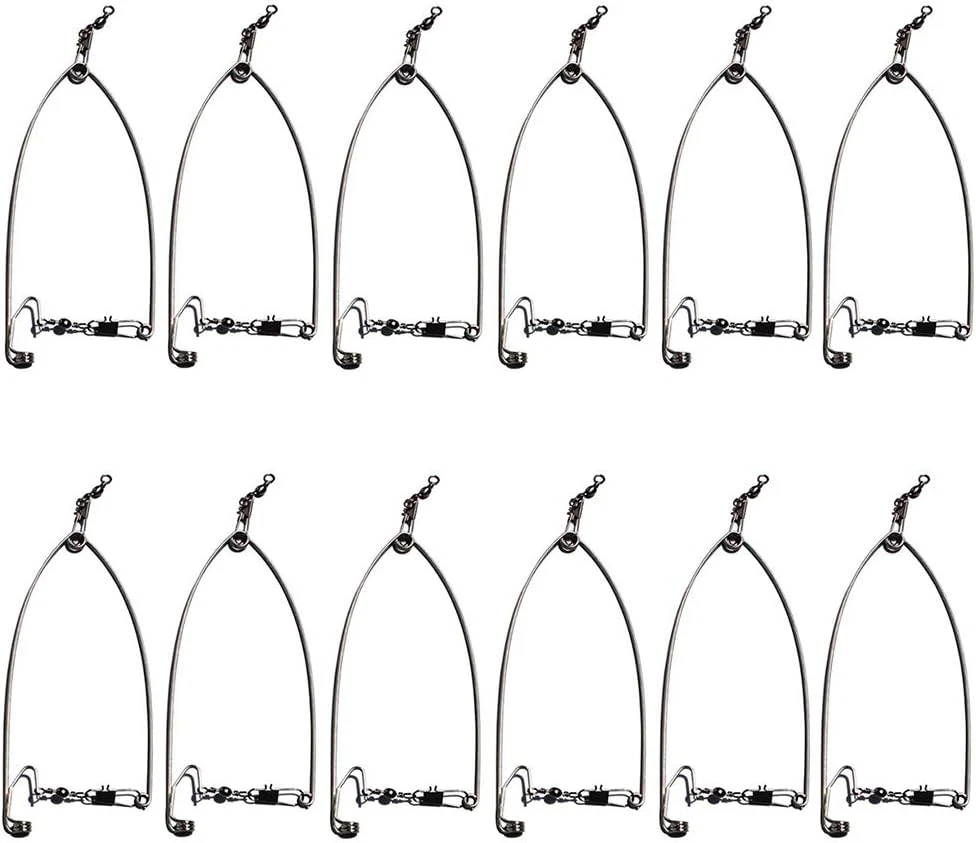

Here's a homemade wire bending setup, some version of which may do what you need:

His use of shanks of worn-out drill bits for the pins is very thrifty. A bag of 100 dowel pins from McMaster Carr will be pretty reasonable, though, and you'd have half a lifetime of spares. For production work (making a lot of one thing), the time invested in a jig like this might be well spent. If you only planned to make one or two of any particular design, the little wire bending jigs blocks are a more general tool, suitable for many different operations. These wire bending jigs are pretty inexpensive (I just looked - about $10 from Grizzly, $12-ish from MicroMark, though there are many sources), but the music wire may be a little hard on them. Even the drill shanks were taking a beating from the music wire in the homemade one linked above.

There are also professional grade "universal" wire and strip benders for light duty work like your project, miniature versions of the full size thing, but they are generally priced nearer $100. Here's one example (there are others):

https://www.kakaindustrial.com/products/kaka-industrial-mub-1-mini-universal-metal-bender

I personally don't have any projects in the queue at the moment that would justify that kind of cash outlay, but for the right kind of job, it might be a bargain price.

With a bit of skill and patience, I have no doubts the aforementioned pliers will suffice.

Kevin

"Them that don't know him don't like him and them that do sometimes don't know how to take him, he ain't wrong he's just different and his pride won't let him do the things to make you think he's right" - Ed Bruce (via Waylon and WIllie)

1

1

Joylynn Hardesty wrote:Are you going to make a how to video? Pretty please?

"Them that don't know him don't like him and them that do sometimes don't know how to take him, he ain't wrong he's just different and his pride won't let him do the things to make you think he's right" - Ed Bruce (via Waylon and WIllie)

5

5

Our inability to change everything should not stop us from changing what we can.

7

7

Country oriented nerd with primary interests in alternate energy in particular solar. Dabble in gardening, trees, cob, soil building and a host of others.

5

5

C. Letellier wrote:would thin stainless steel cable be a better answer for this purpose as it would rust way less? For use in a remote control stove pipe damper I got something like a 350 foot roll for $21 a few years ago off amazon. (1/16"?) It does cable loops nicely braiding it back into itself. working load on the one I got was 105 lbs and breaking something like 300 or 400 lbs.

"Them that don't know him don't like him and them that do sometimes don't know how to take him, he ain't wrong he's just different and his pride won't let him do the things to make you think he's right" - Ed Bruce (via Waylon and WIllie)

2

2

Judson Carroll wrote:

C. Letellier wrote:would thin stainless steel cable be a better answer for this purpose as it would rust way less? For use in a remote control stove pipe damper I got something like a 350 foot roll for $21 a few years ago off amazon. (1/16"?) It does cable loops nicely braiding it back into itself. working load on the one I got was 105 lbs and breaking something like 300 or 400 lbs.

Probably not, because I need a strong spring to set the hook. But, that is a great suggestion for some of the mods I'm considering!

Country oriented nerd with primary interests in alternate energy in particular solar. Dabble in gardening, trees, cob, soil building and a host of others.

4

4

Judson Carroll wrote:

C. Letellier wrote:would thin stainless steel cable be a better answer for this purpose as it would rust way less? For use in a remote control stove pipe damper I got something like a 350 foot roll for $21 a few years ago off amazon. (1/16"?) It does cable loops nicely braiding it back into itself. working load on the one I got was 105 lbs and breaking something like 300 or 400 lbs.

Probably not, because I need a strong spring to set the hook. But, that is a great suggestion for some of the mods I'm considering!

Whoah!! Check out this permie deal!! https://permies.com/w/homesteading-bundle?f=232

"The only thing...more expensive than education is ignorance."~Ben Franklin. "We can easily forgive a child who is afraid of the dark; the real tragedy of life is when men are afraid of the light." ~ Plato

6

6

Our inability to change everything should not stop us from changing what we can.

| I agree. Here's the link: http://stoves2.com |