8

8

“The most important decision we make is whether we believe we live in a friendly or hostile universe.”― Albert Einstein

10

10

9

9

Some places need to be wild

10

10

Air and opportunity are all that stand between you and realizing your dreams!

5

5

Some places need to be wild

6

6

“The most important decision we make is whether we believe we live in a friendly or hostile universe.”― Albert Einstein

4

4

Life on a farm is a school of patience; you can't hurry the crops or make an ox in two days.

Henri Alain

8

8

Air and opportunity are all that stand between you and realizing your dreams!

6

6

Some places need to be wild

6

6

Eric Hanson wrote:John, I have a question and a couple of thoughts:

1) Are those solar panels on top of the golf cart? If so, that's cool!

2) Maybe, MAYBE, consider Lithium Ion batteries

Li-Ion batteries are very light, have spectacular energy density--far better than LiFePo4, and have an absolutely staggering C rating. I don't remember it off the top of my head, but it rivals lead-acid and might even supersede. It also has a very high charging efficiency.

The downside is that they are slightly prone to fires. Now I have plenty of Li-Ion tool batteries and have no fear of them, but they are tiny by comparison. But being so light and so powerful, they might be the right option given that you are driving a vehicle which is sensitive to weight.

“The most important decision we make is whether we believe we live in a friendly or hostile universe.”― Albert Einstein

6

6

Some places need to be wild

9

9

Eric Hanson wrote:

5) Lithium Ion: that’s the stuff!! Its technical specs are hands down the best! And the fire danger is mostly a thigh of the past if obtained from a reliable vendor and utilized properly. But I also get your concerns and understand your reservations. As a bit of a compromise though, I have found that third-party batteries for brand-name tools are both perfectly reliable, powerful and far, far more affordable than the name-branded ones. I bought a pair of 18v, 6 AH batteries two years ago, used them literally every single day till empty and had my first one fail this summer which is exactly on the predicted lifespan. I simply boiled another pair, but by now they were 7AH for the same price. Perhaps an 80, 5+ AH battery (or two, just saying) could be worth something. It’s just an idea, do with what you want.

“The most important decision we make is whether we believe we live in a friendly or hostile universe.”― Albert Einstein

9

9

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

8

8

John Weiland wrote:

Eric Hanson wrote:

5) Lithium Ion: that’s the stuff!! Its technical specs are hands down the best! And the fire danger is mostly a thigh of the past if obtained from a reliable vendor and utilized properly. But I also get your concerns and understand your reservations. As a bit of a compromise though, I have found that third-party batteries for brand-name tools are both perfectly reliable, powerful and far, far more affordable than the name-branded ones. I bought a pair of 18v, 6 AH batteries two years ago, used them literally every single day till empty and had my first one fail this summer which is exactly on the predicted lifespan. I simply boiled another pair, but by now they were 7AH for the same price. Perhaps an 80, 5+ AH battery (or two, just saying) could be worth something. It’s just an idea, do with what you want.

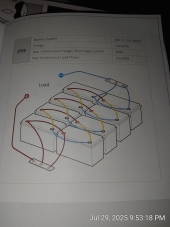

I will try to post more as developments arise, but fall has arrived, we almost frosted last night, and now pre-winter chores are upon us. Thanks for your interest, comments, and advice, Eric. For sure the LiION angle is one that I had dismissed but I suspect that was done too early without propoer prior investigation. Indeed, not sure why eBikes use LiION and not LiFePO4, but that implementation of LiION has sent me down a rabbit hole :-) Using the chart below as an example, it appears that I might be able to use higher-power eBike LiION batteries to meet my needs, at least in a cost-effective experimental way..(??) There appears to be pre-made 48V LiION packs for eBikes that can power up to a 1500W motor....exactly the rated power in my golf cart. As these come in 30 Ah configurations and BMS upper limits of 50 A, then by itself it would be straining the system....but two or 3 of them in parallel should be able to serve my needs -AND- avoid the issues with series connection, something other cart owners have steadfastly advised against. Hmmmm.... the plot thickens! If I were to test a set of LiION batteries in my cart, would I use a LiFePO4 charging profile in my solar charge controller? The batteries appear to come with a charger as you would expect for use in an eBike....but would I be able to charge 2-3 batteries wired in parallel with this charger or require a larger charger?....and would one of the many 48V LiFePO4 chargers out there sold for golf cart charging suffice for his purpose? From what I can see from the specs, such a configuration of batteries would once again be even less weight than LiFePO4s for roughlly the same power capability, perhaps? Much food for thought here.... Thanks!

Air and opportunity are all that stand between you and realizing your dreams!

3

3

|

I like tacos! And this tiny ad:

Learn Permaculture through a little hard work

https://wheaton-labs.com/bootcamp

|