12

12

. The dome is very energy efficient and has surprised us in more ways than one on how much we like it!!!...as well as a few things we would have done differently if we would have thought about it before building it, but such is true with almost anything right?!?

. The dome is very energy efficient and has surprised us in more ways than one on how much we like it!!!...as well as a few things we would have done differently if we would have thought about it before building it, but such is true with almost anything right?!?

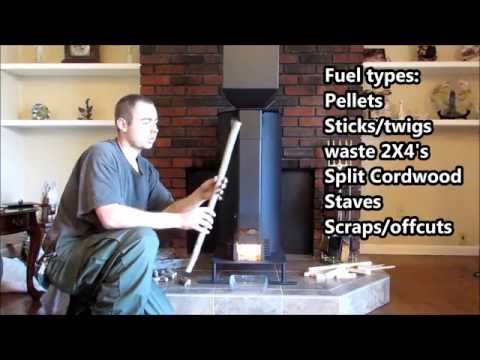

![Filename: Stove-placement-1.png

Description: [Thumbnail for Stove-placement-1.png]](/t/361372/a/276111/Stove-placement-1.png)

5

5

7

7

4

4

How Permies works: https://permies.com/wiki/34193/permies-works-links-threads

My projects on Skye: The tree field, Growing and landracing, perennial polycultures, "Don't dream it - be it! "

4

4

Invasive plants are Earth's way of insisting we notice her medicines. Stephen Herrod Buhner

Everyone learns what works by learning what doesn't work. Stephen Herrod Buhner

3

3

6

6

4

4

2

2

but I don't think we could take too much more away from that. Let me know what you think there. I've added a picture since I find visuals much easier to wrap my brain around.

but I don't think we could take too much more away from that. Let me know what you think there. I've added a picture since I find visuals much easier to wrap my brain around.

3

3

3

3

4

4

3

3

3

3

4

4

4

4

Become extra-civilized!

6

6

Coydon Wallham wrote:I'm trying to picture what your interior ceiling looks like that it would be difficult to run some 6-8" HVAC ducting up and out of or near the center of the dome...

3

3

2

2

Fox James wrote:No doubt a central stove with a chimney exiting dead centre would be not only very efficient but also very cool (excuse the pun)

The required chimney pipe could just be cheap thin wall for the majority of the upper length and could be painted a nice colour.

The pipe would be hung and supported from the roof end.

3

3

2

2

3

3

Become extra-civilized!

2

2

Coydon Wallham wrote:No need to have the RMH in the middle of the footprint with the pipe running straight up and out through the center of the dome top:

Also, with the bench as a stratification chamber, the exhaust can be right next to the Liberator on the central side of the bench.

4

4

Kendal Webster wrote:I'm still debating where to place the exhaust. With any luck I'll start a layout using tape tonight. This will help my visual brain see things better. Also another chance for feedback from the experts here before I start buying materials.

Your picture showing exhaust going up at an angle gives some extra ideas, but the very central part of the dome will not be an option, but any point up to where the loft will eventually go is available. We will see how it all comes together in the next several weeks... or as long as it takes!!!

Become extra-civilized!

2

2

3

3

3

3

Become extra-civilized!

4

4

3

3

4

4

Country oriented nerd with primary interests in alternate energy in particular solar. Dabble in gardening, trees, cob, soil building and a host of others.

2

2

C. Letellier wrote:List of questions. Toying with 3 completely separate answers so don't think this is related.

1. What is in the triangle behind the fridge in the first floor?

2. Does the under stairs closet contain anything essential?

3. Where does the in floor heating lines come up? Tank for that? pump for that?

4. What if the rocket mass heater changed from a bench to a zig zag wall mass and moved next to the stairs?

2

2

Country oriented nerd with primary interests in alternate energy in particular solar. Dabble in gardening, trees, cob, soil building and a host of others.

2

2

C. Letellier wrote:The little closed triangle behind the frig? (potential stove pipe location first floor) Not the room.(more later don't have time now.)

3

3

3

3

2

2

2

2

Glenn Herbert wrote:For mortar, building code in the US requires refractory cement (around $50+ for a 50 lb bag of powder) for all heat-exposed and combustion-product-exposed areas. This would not include exterior bell facing stone or brick. Many builders recommend a fine clay-sand mortar (explicitly prohibited by the code) as the best material.

Clay is easy to dismantle and reuse if ever desired and easily cleans off of bricks. It does not cement the masonry together, just beds units firmly.

Refractory cement is strong and permanent, but may destroy the bricks if you ever try to take it apart. You decide which suits your situation better.

The choice between brick or stone or other exterior material is strictly esthetic and practical, though denser materials hold more heat for a volume. The idea of buying stones boggles my mind... of course I do have a large steep creek with unlimited stone bedding, and any digging job turns up a good number of stones.

5

5

Glenn Herbert wrote:Brick has enough texture that even clay-sand mortar should seal it up in bell walls. Stone that has textured surfaces and shapes that would allow stable dry-stacking can also be reliably clay mortared. Smooth round stones would depend entirely on the clay between them remaining sound and not cracking, and I would never make a single-skin enclosure with them. I would feel good about making an inner skin of a couple inches of cob, being sure to seal up any cracks that develop in drying.

|

I want my playground back. Here, I'll give you this tiny ad for it:

Looking for cold-climate growers to join a GOOF livestream panel (Missoula)

https://permies.com/t/369111/cold-climate-growers-join-GOOF

|