8

8

5

5

5

5

Cristobal Cristo wrote:Bogdan,

I would recommend mixing some local clay soil with straw and try to use it to line your firebox and the afterburner - 5 cm thick layer would be good for the firebox. For the afterburner I would increase the straw to clay ratio and could make it thinner. You will extend the life of the steel shell and will gain some thermal mass.

6

6

Cristobal Cristo wrote:Bogdan,

I would recommend mixing some local clay soil with straw and try to use it to line your firebox and the afterburner - 5 cm thick layer would be good for the firebox. For the afterburner I would increase the straw to clay ratio and could make it thinner. You will extend the life of the steel shell and will gain some thermal mass.

9

9

7

7

6

6

Rico Loma wrote:Hello Bogdan, we are sending our care and respect from sunny North Georgia! I love seeing your projects come together. Whatever you build will be effective and easy on the eyes, I am confident.

Slava Ukraine!

Rico

5

5

4

4

4

4

Cristobal Cristo wrote:If you line the interior of 325 mm pipe with 50 mm if clay mix you will end with around 220 mm of firebox diameter. With the height of 55 cm it should give you very satisfying burning quality. Firebox dimensions of my outside dry stacked cooker are 210x210x500 and it burns so well that I will be building a stove based on this design in my house soon.

For air supply:

-you can either provide it perpindicularly to the firebox on the firebox floor level (please also line the floor with clay - lighter mix with more straw will help to keep the fire hotter)

-or you could provide it from below, but you would need a heavy duty grill; after experimenting I found the grill version to be better burning my eucalyptus firewood which is very dense and produces a lot of coals that need more oxygen (similar to coal that needs grills in the heaters) to fully combust and turn into ash

4

4

2

2

1

1

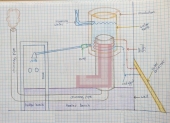

Cristobal Cristo wrote:It's difficult to picture the entire device, but as long as you line it with your clay mix and make sure that the exhaust eventually leaves the bunker, then you are good to go!

6

6

4

4

4

4

Some places need to be wild

4

4

2

2

Eric Hanson wrote:Bogdan,

Nice design. I admire and applaud your resourcefulness. I don't doubt that you are going to make this work.

I think that this thread has given you a lot of very good advice. For my part, I agree that covering (almost burying) the whole assembly of internal stove components in clay is the right idea. Partly to hold all those parts together, partly to seal any potential air leaks, and especially to get some good mass around the stove to store heat!

For what it is worth I tried a very simplified design of a biochar kiln that basically works on the same principles, You can find it HERE:

https://permies.com/t/72466/Cheap-easy-mini-homemade-biochar

My little setup was just to see if I could in fact make biochar--and it worked flawlessly, if on an extremely small scale. Obviously, your plan is for heat, but I don't see any reason that it would not work with maybe just a little adjustment. For whatever it is worth, my kiln did not work very well on the first attempt, I needed to drastically improve the airflow. I don't this this is a problem for you, but I am merely expressing the warning to expect the unexpected.

And in case I have not already mentioned it, I just love that you are making this from spare parts laying around. That part has to be my favorite--that you had to use your ingenuity.

Good luck and please let us know how things work out!

Slava Ukraini

Eric

6

6

4

4

Some places need to be wild

2

2

2

2

Eric Hanson wrote:Bogdan,

You probably either don't have a generator or fuel or you would be using those to finish this project sooner? This frustrates me as I am eager to see how this works out. But really, my frustration is nothing compared to what you have to go through! For whatever it is worth, I am sympathetic and fully on your side.

But even without, I think that you have a great project here to help you get heat to get through the winter on a small supply of wood.

I don't know if this matters or not, but my little kiln did show me a couple of principles at work that I did not anticipate.

#1 My paint can/soup can kiln put out a LOT of heat. As in I was afraid I had it too close to the car! Capturing that heat is about the perfect way to make things work efficiently--and you are on that!

#2 I had to get the oxygen mixture just right. In my case that meant drilling extra holes in the outer paint can. After I increased the Oxygen supply, the smoke completely disappeared and the flame shot up just like a rocket--hence the name! And that flame was almost invisible. Just be careful.

#3 This probably applies more to me than you, but the intense heat did a number on my components--which were pretty flimsy in the first place. After a couple of burns, all of the metal (which is to say the entire device) started to rust incredibly quickly. I assume that the intense heat started to oxidize the metal during operation and once a little rust started, its demise was inevitable. I have heard that kilns like these can only operate for about 10 burns before the components succumb to the intense operating environment. Yours is thicker I assume? This 10-burn limit was specific to similar devises using barrels. Are any of your components made from a barrel or similar type of metal? Most of your components looked pretty beefy. I don't know how long your devise will operate--it might very well work for a long, long time. But I know that the intense heat can do a number on metal. And of course, you are using what you have laying around and you need heat now so of course use those items--but maybe keep an eye out for potential wear and tear.

Overall, amazing project with limited resources. Great work!

Slava Ukraini

Eric

7

7

Rico Loma wrote:Greetings my favorite cousin, I know you stay very busy but please read this other thread, from Kharkiv. She has a workshop from Canadian group to help build mass heaters, free for soldiers and civilians, you have a wealth of knowledge this group will appreciate.

Stay happy , it is always there for us, we simply must grasp happiness. A wise man named Bogdan once told me...

5

5

9

9

6

6

8

8

1

1

Some places need to be wild

6

6

1

1

Some places need to be wild

2

2

Eric Hanson wrote:Bogdan,

Very nice! Almost done.

Can you tell me what the purpose of the curled piece is inside the burn chamber?

Eric

Some places need to be wild

6

6

4

4

10

10

6

6

Some places need to be wild

|

Two tiny ads walk into a bar. The bartender says:

Looking for cold-climate growers to join a GOOF livestream panel (Missoula)

https://permies.com/t/369111/cold-climate-growers-join-GOOF

|