paul wheaton wrote:

More pics!

Video of it in action!

I need to get some more parts like plugs for all the holes.... I am not quite ready for a full length burn. I will try to do a video at that time. I am also hoping to make lots of temperature measurements so I can optimise mass placement and riser height. My feeling is, that the best mass placement gets as much of the surface temp the same as possible. Somewhere around 100 to 120F as around 130 to 140F gets to scalding. I guess parts too high or hard to reach could be a little higher. I know that it used to be law in Russia that a mass heater surface could never get hotter than about 200 to 250... I think I need to look that up again... not sure if it is F or C. I think the book I was reading was American so F (Iron stoves go around 200C or 450F). Anyway, I think that a burn is the amount of fuel (probably measured in weight) that raises the surface to design temperature... not just so it feels right just now. It may feel a bit warm at end of burn and a bit chilly just before.

I need to get some more parts like plugs for all the holes.... I am not quite ready for a full length burn. I will try to do a video at that time. I am also hoping to make lots of temperature measurements so I can optimise mass placement and riser height. My feeling is, that the best mass placement gets as much of the surface temp the same as possible. Somewhere around 100 to 120F as around 130 to 140F gets to scalding. I guess parts too high or hard to reach could be a little higher. I know that it used to be law in Russia that a mass heater surface could never get hotter than about 200 to 250... I think I need to look that up again... not sure if it is F or C. I think the book I was reading was American so F (Iron stoves go around 200C or 450F). Anyway, I think that a burn is the amount of fuel (probably measured in weight) that raises the surface to design temperature... not just so it feels right just now. It may feel a bit warm at end of burn and a bit chilly just before.

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Satamax wrote:

Hey Len, nice'un!

I wish i could find a big water tank like this.

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Holistic wrote:

My question is not exactly about building a portable RMH, but building using a more lightweight mixture than traditional cob. This summer I built a small home (approx. 400 sq. ft) that looks like a houseboat/ark and it has a wooden floor. I intend to use the information from Ianto's book regarding if you are a renter, but am also trying to deal more easily with the weight issue.

I am therefore wondering if anyone has experimented with the Hypertufa mix: portland cement, peat moss and vermiculite. It is much lighter and apparently has excellent insulation qualities.

Would anyone kindly care to offer an opinion? I am a single mom in Nova Scotia, Canada, trying to figure this out on my own.

I would like to get about 12 hours or more with mass. But it doesn't matter so long as it makes it to 10 hours or even 8 as the house is empty all day and even with no heat 12C is about as low as it gets inside... On Vancouver Island where really cold is -10C.

I would like to get about 12 hours or more with mass. But it doesn't matter so long as it makes it to 10 hours or even 8 as the house is empty all day and even with no heat 12C is about as low as it gets inside... On Vancouver Island where really cold is -10C.

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Satamax wrote:

Len, two or three things which come to mind.

Also simple tools that don't require too much skill to use. Anywhere I have welded, a screw or two would have worked. It just means drilling holes and putting a screw through. Old cars have lots of self tapping body screws on them that are a bit stronger than the sheet metal screws and would be better for the thicker metal of the core.

Also simple tools that don't require too much skill to use. Anywhere I have welded, a screw or two would have worked. It just means drilling holes and putting a screw through. Old cars have lots of self tapping body screws on them that are a bit stronger than the sheet metal screws and would be better for the thicker metal of the core.

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Satamax wrote:

Hi Len,

Well, there's one thing which comes to mind straight away, heat differential. I mean the internal draft is suposed to work betted with a bigger heat differential between the heat riser and the radiator, and here you're kind of insulating the radiator.

So you're not cooling the exhaust gasses as fast as you used to.

I'm ready to bet your exhaust temp have gone up.

Sorry to be a pain.

But i think that's why the mass is added later, on the flue, so you cool the remaining heat in the fumes.

)

) Anyway, I think if I can get this to work I will put a window in the brickwork and drop an old laptop screen in there with a fireplace video loop

Anyway, I think if I can get this to work I will put a window in the brickwork and drop an old laptop screen in there with a fireplace video loop

.

.  They could be criss crossed so air can travell through them, pushed by a fan when hot air is needed. I picked up four from an army base in a nearby town. That's what gave me the idea.

They could be criss crossed so air can travell through them, pushed by a fan when hot air is needed. I picked up four from an army base in a nearby town. That's what gave me the idea. God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Satamax wrote:

Len, two things, i bet you read about my idea of a flat flue5à to 1 meter wide, 2 meters high 5cm thick, one intake from the rocket flue, one exhaust going back to the chimney. Either bare or surounded by bricks.

Another wardrobey plan, you know thoses old steel grey lockers? Drill a hole in one side, one on top fit the exhaust pipe of the rocket in there, and fill with bricksThey could be criss crossed so air can travell through them, pushed by a fan when hot air is needed. I picked up four from an army base in a nearby town. That's what gave me the idea.

Satamax wrote:

Well, there's one thing which comes to mind straight away, heat differential. I mean the internal draft is suposed to work betted with a bigger heat differential between the heat riser and the radiator, and here you're kind of insulating the radiator.

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Satamax wrote:

Len, what i have noticed on my four incher, big wood (well!) burns better when i have embers at the bottom of the feed tube. I can burn up to 2.5x2.5 of very hard and dense ash. It carries on burning as long as the corner of the feed tube and burn tube isn't too cold. I think the secondary air intake in your case should be to the sides.

Well, if ever you realy need it. I think first of all you could try putting fire bricks instead of roxul, just below the burn spot, to add heated mass, which would keep the embers, or fresh wood burning.

Air intake on the bottom cools down the steel imho.

And the first air intake compared to the volume of wood to be burned is too big. My sense tels me to put a flange of about 1/4 of the diameter of your intake tube at the bottom, not to expose the wood to too much air, and create an air swirl through the embers and sticks. As well it would slow down the flow of air within the embers, keeping them hot.

The guys who invented this did well, the J shape , with a short feed tube is the best i think. May be a litle secondary air. Using fire bricks isn't daft, because it keeps the heat there for the burn.

I think J shape is not drafty enough to prevent smokeback when windy. Mind you, i haven't used a very tall heat riser yet.

By the way, don't think i criticise all the time. I envy you, having been able to source a nice water tank, doing nice welding. Using different ideas etc. It's just my feelings tells me that this horizontal air intake is too big. That your mass under the burn spot is too small.

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Satamax wrote:

Hey Len, i've thought about manufacturing stoves too

The problem is that i'm of the intuitive type, and, even if i'm not too dumb, i am way to lazy to take a scientific aproach. Like doing burn tests, to get the proper stochiometric mixture, calculating, and all the stuff which goes with it.

Well i'll get back to few points, in my four incher, i can get it to run unatended for an hour. I think that is because of the very thick steel i have gathered for the burn tube, it glows to dark red at least, and is insulated by all the vermiculite i've put around. But it has some mass. I just feel the thin steel tube you've used doesn't have enough mass, so it doesn't keep the heat at the burn spot, hence the idea of using fire bricks. Or any type of material which is refractory, to add a litle mass.

I was also saying about a litle bafle in front of where the embers should stay, this would create a swirl of air, but also keep them from cooling down too much. I think it's in Ianto's book, where he states don't use a round tube for teh J because there's isn't enough turbulence.

I was wondering does your fire goes up the sticks? Into your feed tube?

I haven't get a good seal where the cartridge joins the burn tunnel... I was too keen on trying it with big wood and some mass

I haven't get a good seal where the cartridge joins the burn tunnel... I was too keen on trying it with big wood and some mass  The top is sealed and so there is no oxygen. The flame all goes towards the riser. Other people have had an open feed as well as the open air intake on the front, but the feed has to be much shorter so as not to act as a chimney. Someone had the idea of putting a hoop higher up to hold fuel up while it burns... the only problem is with all that heat if the fuel starts burning above the feed tube at all there is a fire outside the heater. So I want to seal the fuel off from air till it gets to the primary burn area.

The top is sealed and so there is no oxygen. The flame all goes towards the riser. Other people have had an open feed as well as the open air intake on the front, but the feed has to be much shorter so as not to act as a chimney. Someone had the idea of putting a hoop higher up to hold fuel up while it burns... the only problem is with all that heat if the fuel starts burning above the feed tube at all there is a fire outside the heater. So I want to seal the fuel off from air till it gets to the primary burn area.

Len wrote:

It's working pretty good actually... good enough to bring it inside. There is no smoke back and the output is slow enough to go into my 4inch flue.

So I can try out my portable mass bench idea first. I can see what the final flue gas temperature is before I bring it inside. I think I will get some of that flex aluminium drier vent for trying it out. I can see if the flue gas is warm enough for a vertical chimney flue.

So I can try out my portable mass bench idea first. I can see what the final flue gas temperature is before I bring it inside. I think I will get some of that flex aluminium drier vent for trying it out. I can see if the flue gas is warm enough for a vertical chimney flue.

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Satamax wrote:

Hey Len, so you're plumbed in now?

Hoser Hatfield wrote:Hey Len,

It may be a naive rookie question but how does the roxul hold up in the riser? I imagine well or we'd have heard about any problems and changes you made. I ask because I am at a point to insulate the riser(wish I had referred to your pics to see you used it on the burn tunnel too) and yours is the first I saw using insulation like that as opposed to clay /cob etc with maybe saw dust mixed in it.

Len Ovens wrote:

I am planning to set the big half this way (Tim smiles nicer when he is not posing):

http://citylivingnaturally.com

A sustainable approach to life in the city

Sandra Ellane wrote:

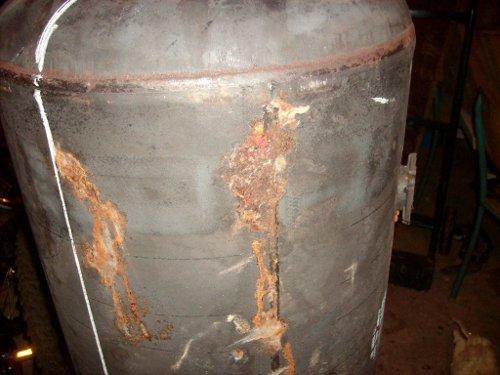

This has been such a helpful and informative thread. I just saw a free gas water heater posted on Craigslist, so that may be the way to go for me (or wait for an electric one).

Think of how many houses you live by then divide that by ten and you get the number of tanks that get replaced every year... There are lots of them around. I have found them easier to find than barrels.

Think of how many houses you live by then divide that by ten and you get the number of tanks that get replaced every year... There are lots of them around. I have found them easier to find than barrels.

Also, when I look at cut away diagrams of them, there's a layer of insulation between the outside and the inside of the tank. What did you do with that layer- it doesn't look like yours has that layer. Will that insulative/double layer be a problem?

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Satamax McCoy wrote:Hi Len.

Daft question, are thoses insulated type wated heaters, or the old ones you used to find on boilers?

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Satamax McCoy wrote:Len, i'm on your tracks. Gotten myself a water heater yesterday. About 6ft tall.