2

2

Silence is Golden

For all your RMH needs:

dragontechrmh.com

1

1

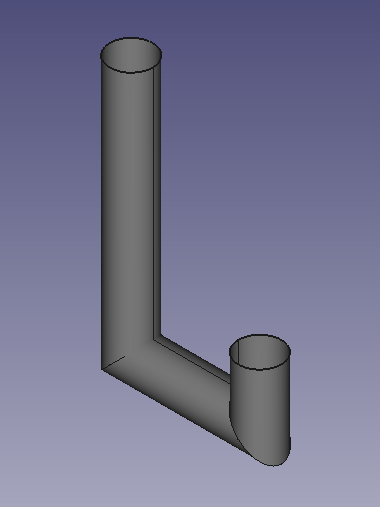

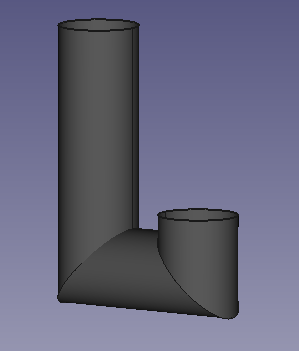

Gerry Parent wrote:Hi Mark, Welcome to the forums. The ratio 1:2:4 is broken down as follows : 1 means feed tube, 2 means burn chamber and 4 means heat riser. Since all the photos (minus the top middle) one doesn't have a burn chamber, the ratio is kind of irrelevant from the start. I don't have any experience with making a modified L tube like these ones but I do know that I've heard several people complain that they don't consistently feed the wood very well at a 45 degree angle - The wood doesn't slide good and gets caught up more easily than a 90 degree feed tube.

Perhaps someone with more experience with making one can chime in to help you.

2

2

Silence is Golden

For all your RMH needs:

dragontechrmh.com

Gerry Parent wrote:Mark, Seeing as you are using it just for cooking with nothing to slow or add friction to the exhaust (barrel or mass), the burn tunnel can be shorter without any problems. The ratios are mostly guidelines as there are so many factors with every build that can affect what you can get away with in modifying them.

Have you considered a square tube rather than round? This is what I used for my first RMH build and had an ash tray (made from a recycled cooking oil can) and a metal grate that I made from 1/2" rebar that worked quite well.

Glenn Herbert wrote:Rather than depend on the iffy feeding character of a slanted feed tube, I would go with a simple L-tube. A grate in the bottom like Gerry's, or even just a bent piece of metal that gives an air path to the back of the burn tunnel, would help.

A J-tube needs no grate or air channel. A 4" system is small enough that cleaning ash becomes difficult, and an ash cleanout would be needed.

Are you looking for a stationary outdoor cooking stove, or a portable one, or a traveling/camping one? That makes a big difference in what will be most practical.

1

1

Mark Tamp wrote:How do the L-tube works? The fire is directly on the bottom of the heat riser? Or you don't put the wood all the way in?

Are there any recommended dimensions or a good specific design for a small L-tube?

Silence is Golden

For all your RMH needs:

dragontechrmh.com

1

1

1

1

Rob Millard wrote:Here is a 1st gen. cooker I whipped up in an afternoon to try a proof of concept. The air holes I added up the side were to induce a vortex in the exhaust. Originally 5 holes with 2 of them below the top of the feed tube junction were muddling the air path. Once I filled in the ones below the joint then enlarged & added one it worked noticeably better. I probably could have done just one or even no holes but it was a test project so. (Shrug) This shot was after it had just gone out & before my mods. The tube was 3" since that was what I had & the riser was about 18" tall. The top were just offcuts of the same with bits of bar to hold them together in an open grid.

1

1

|

The barrel was packed to the top with fish. And he was shooting the fish. This tiny ad stopped him:

Learn Permaculture through a little hard work

https://wheaton-labs.com/bootcamp

|