MS Tûranor PlanetSolar circumnavigated the globe with just solar power. It has 537m^2 of panels producing around 110kw of photovoltaics

My 3 Questions For You

Swales and check dams can be dug via electric power with BEV equipment already on the market. Using tech from the Solar Car Challenge we could dig these with solar directly to motors instead of via batteries. I think solar-direct would use a lot less resources+$ and have less externalities than any other mobile power tech. I think this could enable scale-able, low cost, desert>swale>seed+microbiology>flash flood>planned rotational grazing>meadow [fast land restoration] sequences. Is this an important thing for me to work on? What am I missing? Would you like to help?

Current Battery Electric Heavy Equipment

Plug-in battery-electric heavy equipment is already* on the market and is higher performance** and more agile than diesel. BEVs (Battery Electric Vehicles) are more expensive to buy than diesel, but electric is probably a lot cheaper over its life cycle. Electric is clean and quiet. BEV heavy equip is new, maybe that's why the equip's capital costs seem overpriced relative to the cost of their components.

Solar for Swales, Concept

-solarcarchallenge.org

-solarcarchallenge.org

Solar panels directly wired to motors are not only cheaper than batteries, but panels lifecycle is 1.5x-10x longer than batteries. So the effectiveness value would be much greater on a machine which avoided both diesel and batteries by going photovoltaic direct to motors. Going solar direct has design challenges related to the large surface area used by panels, but because it might use orders of magnitude less resources than a diesel drive or hybrid drive... while still avoiding the massive capital cost of battery electric drive it is probably a good candidate technology for scalable, climate positive, carbon negative, eco restoration earthworks. Solar panels have dropped in price by at least 10% per year, every year since 1980 and they keep getting more efficient. The power per surface-area density of solar-panels-direct-to-motors is massively lower than diesel or batteries... this is why the first picture looks like a megafauna Stingray made outa monocrystalline solar panels bolted on top of a high performance yacht. I dont see this as that big of a problem in open landscapes.

Why modern deserts sometimes greatly benefit from access to scalable earthwork digging ability

Earthworks may be more helpful in deserts during climate change than in other ecosystems and climates because global rainfall is increasing with rising temps but is more haphazard and more extreme. Many deserts, desertified ag land, and wide concrete regions are prone to flashfloods. See below.

Factor in groundwater depletion and soil loss from big ag and the result tends to be desertification. Fortunately, swales and check dams can slow flashfloods down enough to recharge groundwater and turn deserts back into savannas.

Solar Swale Bulldozer or Motor Grader

Imagine a 100m long centipede-looking machine with solar panels on its 5m wide back.

The solar panels would produce roughly 100kw (~135hp) of power***.

Wheels where its legs would be.

Some digging blades in front or underneath.

Cameras monitor each digging blade.

It would have hinged trailer sections just like a train for maneuverability.

Maybe it would be slow, idk. It could certainly be upgraded to autopilot itself if it was slower than is worth having a driver for.

100kw is how much power a 14,000kg bulldozer with a 3.5m blade is rated as having****. I would rather it has distributed drive motors on many wheels throughout the machine... but for mechanical force transfer reasons it might need to look like a regular dozer or grader with a long trailer-cape of solar panels. Distributed drive motors would allow traction with much lower ground compaction relative to the conventional high-psi-for-traction approach.

Solar Shovel Climber

Imagine you're laying on a skateboard and pulling yourself up a hill with a shovel by shoving it into wet ground uphill and tugging yourself towards the shovel. That same motion could be done by a machine to dig a series of boomerang swales for trees or check-dams for beavering surface water into groundwater. This motion might cause less fungal and structural disturbance to the swale or dam than an excavator bucket method. This motion may also be more energy efficient per effect. The machine would use its weight to pull downhill against the shovel in the ground. It would also use tire traction to pull against the shovel by reversing once the shovel was in the ground .

Solar Climate Swaler (SCS) Biz Plan Draft 0.2.1

0. research, consult, design, make & test tiny prototypes, rework

1. seek partners

2. seek investment, seek loans or self fund it

3.make solar diggers

4. buy or contract low cost desert land

5. map, analyze, test, monitor, consult with neighbors, get permits

6. design the swales and check dams needed to sink the typical annual flash flood

7. buy biochar or make it from clean mill scrap from the nearest post-wildfire area

8. make good

compost with with the biochar and with added local microorganisms and confirm its good via a pro

9. collect rainwater onsite or get water from the ground or neighbors or via trucks

11. make actively aerated compost tea with some of that good compost and have a pro check its quality

12. water the area to dig and cut using that good fresh compost tea, watered down

13. dig and cut with the SCS, while recording data on performance, effects, harm caused, power consumption etc

14. add a lil good compost and native grass seeds. Either mulch or plant the seeds. Plant larger native plants

if temporary irrigation can support them until the swale's catchment can

15. remap the area and review data while waiting on rain

16. monitor and make adjustments when it rains or flash floods

17. let the seeds grow

18. holistically planned graze or it sell it to someone who will definitely do so properly.

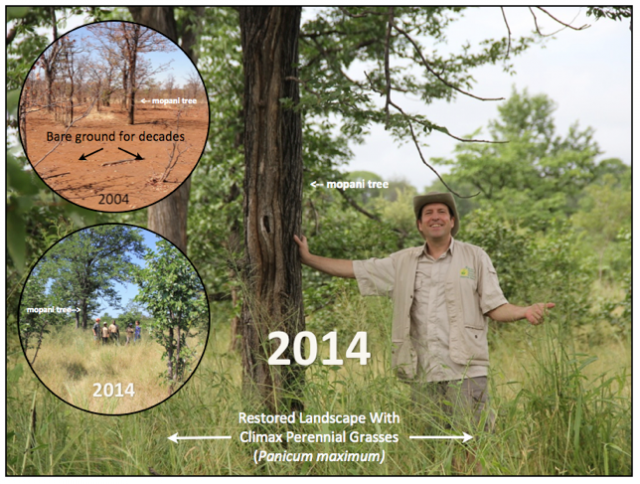

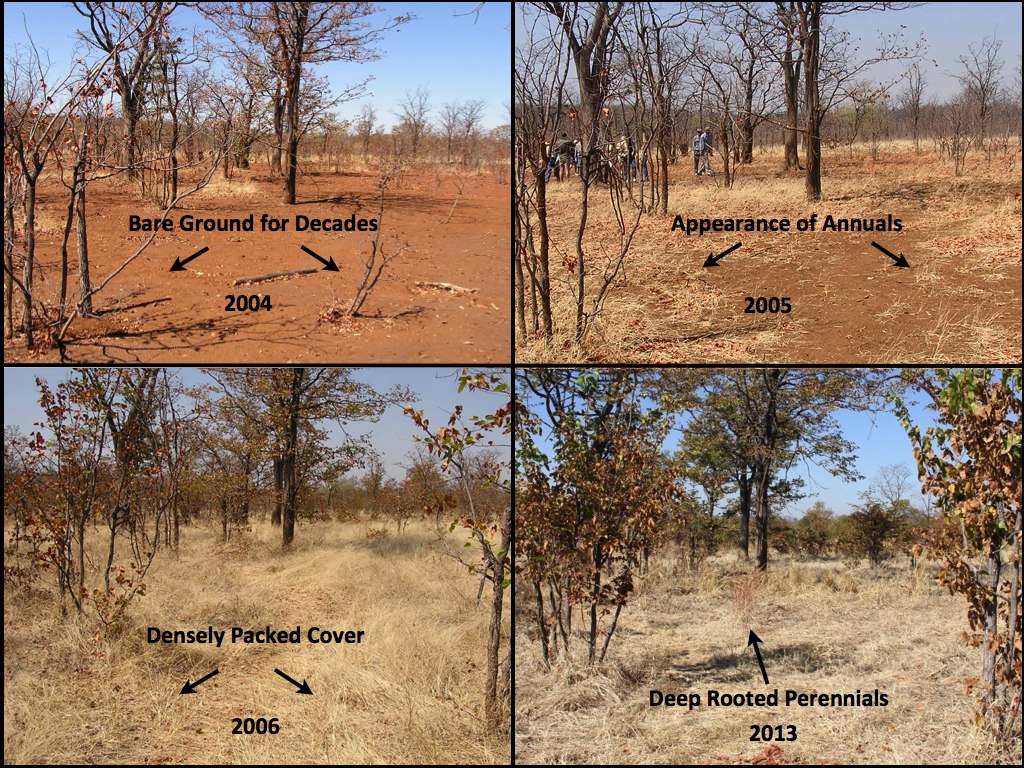

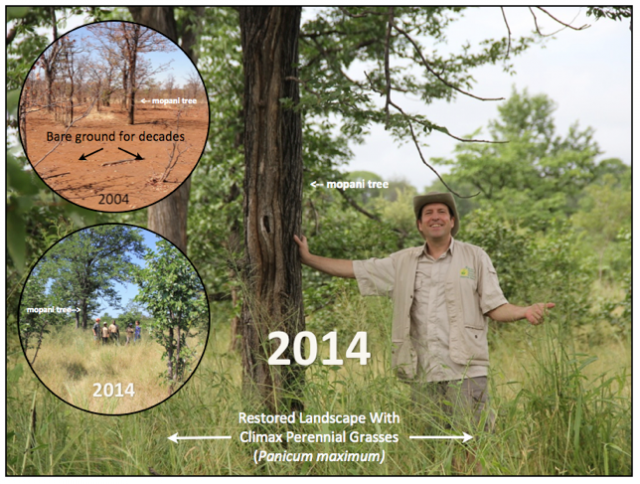

- From Seth Itzkan's 2014 article about HPG available on planet-tech.com Note, they're just grazing properly as far as I know. I think they aren't even using swales, biochar, added native seeds or compost tea

- From Seth Itzkan's 2014 article about HPG available on planet-tech.com Note, they're just grazing properly as far as I know. I think they aren't even using swales, biochar, added native seeds or compost tea

19. improve methods and repeat elsewhere if justified

*:

- Cat already makes an expensive, heavy, battery electric loader. Its mostly used in tunnels.

https://electrek.co/wp-content/uploads/sites/3/2019/01/electric-caterpillar-excavator-e1548740266295.jpg?quality=82&strip=all&w=1600

https://electrek.co/wp-content/uploads/sites/3/2019/01/electric-caterpillar-excavator-e1548740266295.jpg?quality=82&strip=all&w=1600

- A Norwegian company modded a huge Cat excavator to be fully electric, using 300kw of battery storage. Lots of Cat equipment already has its main drive via electric motors [bc they're higher performance] and get charged up via onboard diesel generators. So, I assume the Norwegian folks pulled out the diesel generator and replaced it with the 300kwh of batteries and kept the stock electric motors. I think this prototype became the "Cat zline", maybe as a cat publicity stunt.

- Montreal has used 3 EV buses since 2017. The buses alone only cost about 1,200,000CAD each vs 900,000CAD each for diesel, however they also managed to spend 800,000CAD each on three quick-charge stations... wow.

- Green Machine Co makes the e240 and e210 Electric Mini Excavators, its a BEV. I think the e240 costs over $100k though which is about 2x to 3x higher than an average mini excavator.

" This machine is the first in the world to match the performance metrics of a diesel powered unit – and with a lithium-ion battery.

• 100% cleaner than diesel

• 90% less expensive to operate

• 50% quieter

• Zero Emissions " -from Green machine co website

**:

Electric vehicles may retain their value a lot longer than diesel. Plus, in 2020 the fastest production supercar will likely be the electric Tesla Roadster with about a 2 second 0-62mph acceleration. Its going to cost around $250k (don't buy it) and all comparable performance gas hypercars cost over $1M. 2019 BEV sedans above about $40k price range also tend to be massively higher performance than similar priced ICE (gas) sedans. Therefor electric cars are probably both faster than gas and massively higher performance per cost than gas... but for now this may only apply to rich people. The lifecycle cost of ownership of a BEV which you solar charge at your home is massively cheaper than a similar priced ICE car. Fortunately this is already true across the car price range.

***:

100m * 5m = 500m^2 of solar panels.

the sun shines about 1kw per m^2

20% solar panel efficiency is realistic

500m^2 * 1kw/1m^2 * 20% = 100kw

100kw / 0.74kw/1hp = 135 horsepower per

**** :

John Deer - "

700k crawler dozer, Engine Netpower = 97kw, 130hp at 1800rpm. Operating weight = 13,733–14,193 kg (30,275–31,290 lb.) Track On Ground = 2,590 mm (102 in.) Blade Width Range = 3,200–3,658 mm (126–144 in.)".

https://www.deere.com/en/dozers/

Cat - "

Since 1996 the D6K at 125 hp and 28,409 lb... has been introduced"

https://en.wikipedia.org/wiki/Caterpillar_D6

dutch solar boat race

https://www.upsbatterycenter.com/blog/wp-content/uploads/2017/03/Dutch-Solar-Competition--e1490032448798.jpg

SCS research questions:

A. Toxicity levels, lifecycle and recycle-ability of contemporary, efficient solar panel types and brands?

B. Psi heavy vs distributed traction for drive?

C. Price of Sunpower's 25% efficiency, flexible panels?

D. Feather-like mounting of panels to trailer for aerodynamic resilience?

E. Relevance of making a ebike powertrailer as a prototype component to add to a micro-bulldozer or micro-motor grader later?

F. Does the probable depth of misuse of SCS tech by big ag and ignorant land owners outweigh the benefits of inventing it?

This post is a work in progress and I intend to keep improving it. I intend to publish it more widely if the concepts improve via my research, your input here and at the Bioneers conference in San Rafael, CA this weekend.

2

2

Factor in groundwater depletion and soil loss from big ag and the result tends to be desertification. Fortunately, swales and check dams can slow flashfloods down enough to recharge groundwater and turn deserts back into savannas.

Factor in groundwater depletion and soil loss from big ag and the result tends to be desertification. Fortunately, swales and check dams can slow flashfloods down enough to recharge groundwater and turn deserts back into savannas.

2

2

1

1

1

1

4

4

1

1

3

3

1

1

2

2

3

3