If I understand your description, you've made what is commonly seen on Youtube, a rocket stove made from square steel and then have a metal barrel sitting over the top of the L, and the tall riser part of the L has sand packed around it? If all of that is correct, I think that build is going to have serious draft issues based on the design.

Unlike a lot of Youtube videos, I don't think you'll find many here that would recommend using metal in the burn tunnel or riser, because a properly functioning rocket heater will destroy that metal very quickly. To get it to perform better, I would replace the sand with perlite or an insulating material like

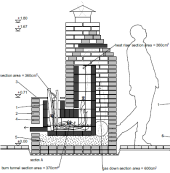

Superwool. That insulation should surround the burn chamber and the heat riser, some will use insulated firebricks as well. A popular riser setup is known as the "5 minute riser", which is a piece of 8" duct with 1" refractory blanket like Superwool inside to make a 6" riser, or 10" pipe to make a 8" riser.

That insulation keeps the riser hotter than the surrounding insides of the barrel, which helps draft. The other insulation helps keep the heat in the combustion area, to provide the maximum heat for the best combustion. Other than the chance a piece of paper or other material is blocking your airflow somewhere in the barrel, I expect it's the metal+no insulation causing draft issues. I would really recommend removing it from the house for further testing, to avoid any CO in your indoor air, or get a CO detector sitting nearby at a minimum.

1

1

1

1

2

2

1

1