Howdy folks!

So I’ve started to work out and spec the build plans for a new RMH, based on Matt Walkers original cook stove design. It’s going to be a bit before we actually start construction of the stove, as we are in the process of trying to get a tiny house finished before the snow flies. (figures crossed)

Have been in touch with Matt a few times and corresponded with him on our build. He has been extremely helpful, as always, but also wanted to document the build process here, so that others can learn and we can all grow and understand more together.

Our design will be based on the Walker Brick Cook Stove/WALKER RISER-LESS COMBUSTION CORE. This core is an open source design under a Creative Commons License. We’re donating to the cause and ask that anyone who decides to use this design do the same.

This is our second build. First was last season as a bell bench CFB J-tube. With the help of Matt and all of you here, we have a successful stove and a better understanding rocket mass technology.

Having said that, the J-tube is a much simpler geometry and a rather easy build in hind site. 6” (15cm) chimney flu duct= 15cm through out. I just cut all my CFB pieces so that all sides of the core were an exact 15cm.

i.e. feed tube=15cm x 15cm, burn tunnel=15cm x 15cm, heat riser= 15cm x 15cm.

Between those spec perimeters, the CFB insulated core and the “no manifold” direct connect to the bell, I think we were successful in our first build. Really have next to no problems getting draft and running the J-tube we have.

This new build is a bit more technical and so I’m taking the time now to try and understand the details of what we are planning to do. Matt makes a point over and over that a stove should be “a work in progress”. Build and tweak as you go. This approach resinates with me, as I feel that the design perimeters for each stove is depended on the needs of the builder and the environment in which it will be used.

With this in mind, I’m more than happy to keep fine tuning as we go. But first off I need to get my head around the stove, its technical aspects and build components. I’ve watched just about everything there is on the subject and spent late nights reading all the techie stuff on Donkey’s and Peter’s site. Some of which still escapes me for sure.

The other thing that attracts me to Matt’s stove philosophy is the idea of designing stoves that are stable in varying conditions. Like I’ve said before, we’re not trying to win the science fair here, just build a solid stove that is reliable and relatively efficient.

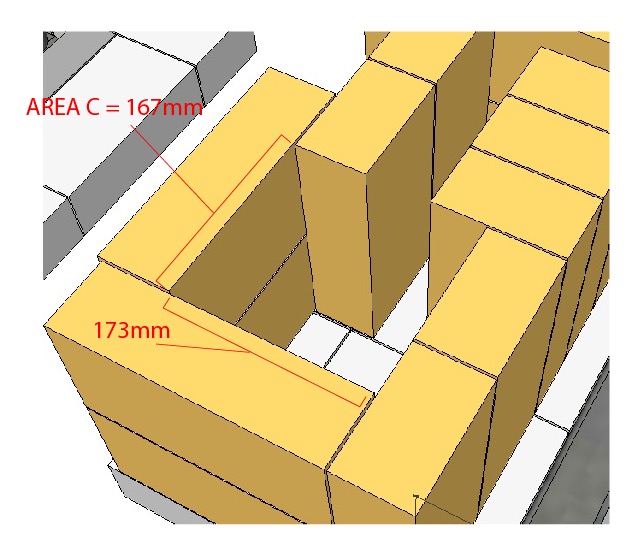

Here is my first SketchUp mock-up of the intended core. It’s been built from zero, referencing Matt’s riser-less core photos on his site.

Link:

https://walkerstoves.com/walker-riser-less-combustion-core.html

As well as a SketchUp file created by Berry on Donkey`s

Appreciate these technical specs from Berry, however his mock-up has some of the bricks squished into other bricks (virtually) and does not account for any mortar in the build. I have rebuilt the core in layers adding a 2mm mortar allowance between each brick. I’m not sure that this is the correct allowance, but just based it off of my findings on the web. I have made each layer of bricks in different colors so that it will be easier to reference, and made a darker shade of any bricks that need to be cut to fit the build.

Here is a look at what I have to date. I think I understand how the flow of the riser-less system works, basically winding its way up and over the cooktop and then into a down draft chamber that empties out into a bell bench, in our case.

Link:

https://we.tl/t-dH0O1HYLP7

Matt said I should “maintain a CSA of 29” through out”, but to be honest I’m not entirely sure what that 29” is referring too. The core design changed size a number of times between the port and downdraft space. I’m following the dimensions from Berry’s SketchUp file as closely as possible while allowing for mortar and the IFB (insulated fire bricks) we will be using in our build.

Are these dimensions/plans for an 8” system?

Should we be using 6” or 8” flu/exhaust pipe for this build?

Here are a few other areas I feel we need some guidance on:

Secondary Air:

1. Better understanding of how to build and implement the secondary air. Not sure I can get RA 330. Do I use standard square tube stock? What dimensions do I need for the horizontal portion? (8” or 6” system) How tall should the vertical portion be? Do I need to close off, weld shut, the end of the horizontal tube nearest the port?

2. How do I “suspend/raise the secondary air tube so it sits flush on the burn chamber floor? It’s just hovering in space in the SketchUp mock-up.

3. Do you fill the area behind the secondary air tube, in the floor channel, with a small piece of IFB?

Door:

Thinking of constructing a simple plug style door to begin with, similar to what Matt showcases as an option in his “Building Stove Doors, Dampers, and Hardware” instructional video.

Link:

https://www.youtube.com/watch?v=K7Zu7rSpnzs

Probably something that incorporates tensioning pins for seal. Questions:

1. I attach a steel angle iron frame to the brick core face? This frame is attached to the core on the inside face of the brick liner? (face of the bricks that make up the opening to the core?

2. Flange is mounted to the angle iron with bolts?

3. The door has a hole for the primary air? (which can be closed off separately from the secondary air)

4. Secondary air has its own hole in the steel/aluminum door flange? (which can be closed off separately from the primary air)

This is a bit unclear after watching Stove Chat 16 where Matt talks about the door as if it covers both the primary and secondary air. Maybe there has been developments in design since the ones shown on his site.

5. How should I be approaching this door? Size? Fabrication? Plug style for simplicity or hinge style convenience?

6. Is this being mounted to the IFB core or to the cob/stone skin in our case?

Cook top:

Thinking of using a large piece of 5mm steel to start with. Likelihood of us finding a glass cook top is not very likely, but will keep looking.

1. Just cut to fit the dimensions of the IFB perimeter and seal with cob correct?

2. Any tips on seasoning this top?

Bypass/Baffle:

1. Should we be incorporating a bypass into our system?

2. Should it be located in the spot pictured in the Attachment?

3. Will something like this work or are we still too hot for metal? (See attachment)

RMH base insulation:

This is a topic that I feel a bit uncertain of. In our first build I threw down a “bunch” of perlite and clay in a hurry and just started building on top. I’m a bit obsessed with this at the moment as I’m OCD and convinced we are loosing tons of heat through the floor with no way to tell. Want to maximize insulation this time around.

1. If we are using full IFB for the floor of our core, what should we be laying down under that? (the core will be set on tamped cold earth)

2. Is putting down a layer of glass bottles as a thermal break a good idea?

3. How do you know when you really have enough insulation under both the core (if necessary) and the bell?

I probably sound like a broken record on this point, but it just keeps haunting me and it seem to be the one topic that never gets very much attention, Maybe a question for Stove Chat?

That’s probably enough for an opening post.

All insights and comments are welcome.

I will do my best to clearly provide as much information about our build as possible throughout the process so that we can all learn together. Let me know when things are unclear or needs more details.

Feel free to follow this design thread and use what ever you like, just remember that it is based on Matt’s open source core, and if you decide to use it please respect his time and innovations with a donation when possible.

Thanks again in advance for your time and looking forward to more rocks mass madness in the weeks and months to come…

Sincerely, Peter & Co in Hokkaido

P.S.- For anyone reading this and thinking of building their first stove, START NOW, START LAST WEEK…:)

5

5

2

2

2

2

1

1

2

2

4

4

1

1

4

4

4

4

3

3