Collection of 14 Permaculture/Homesteading Cheat-Sheets, Worksheets, and Guides

will be released to subscribers in:

soon!

4

4

5

5

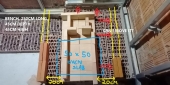

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

5

5

4

4

3

3

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

3

3

4

4

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

5

5

Best luck: satisfaction

Greatest curse, greed

13

13

www.emilsagroforest.com

3

3

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

3

3

Finally! An Online Garden Master Course for permies!

How Permies.com Works

3

3

5

5

2

2

Randy Butler wrote:Hi Tammy.

Great score on the fire bricks! Are they light (insulating) or heavy? That will give a better idea where to use them.

My intentions are to use standard firebrick for the lining of the firebox, then insulating FB for the remainder of the core.

Also, insulating FB for the riser - although now I'm not sure if I'll go with the PvdB batchBox or his DSR3! Decisions, decisions!

Are you planning an oven? If so, black or white? I'm going with white so I can cook while the fire is running and plan to use refractory to build the walls. Can't remember where, but one of the heater threads goes into detail about the forms.

No doubt, with the wealth of knowledge available on this forum, you should get all the information you need.

Happy building!

Randy

3

3

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

4

4

3

3

thomas rubino wrote:Alex;

Superb build! Looks great!

Have any pictures and tips to share from your build?

www.emilsagroforest.com

2

2

1

1

www.emilsagroforest.com

1

1

www.emilsagroforest.com

| I agree. Here's the link: http://stoves2.com |