posted 4 years ago

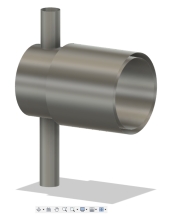

I think OP is confusing the terminology a bit. Heat Riser, as commonly used, is commonly considered the vertical column just after the burn chamber where gases rise up and burn off hydrocarbons. In the typical RMH, this riser is surrounded by the barrel, which in itself can be considered a bell of sorts, where immediate radiant heat is made available. I was going to do a barrel surrounded by bricks set in a staggered pattern so the space of about one third of a brick would expose the barrel, tempering the rate of radiant exchange while adding some mass to it for longer term radiance.

I don't think the Walker Stove really uses that much more wood than other RMH type stoves, but it does have a small firebox and needs to be fed often. But then again, there are always trade-offs to any design. What Matt does have is an excellent stovetop for cooking on. Even if depending on it for a primary heat source might get cumbersome.

I would like to have a BatchBox which has a small cooktop and an oven, and also heat a rather largish bench. Have to be careful not to ask the core not to do too many tricks at once though, or the builder may find himself disappointed.

My advise is to look at how cooktops are constructed out of steel, and fabricate one like that, or go with Matt Walker's ceramic glass cooktop, if you can source the material. Personally, I'm having a hard time with that.

Good luck.

Where there is Liberty, there is Christ!