I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

1

1

1

1

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

1

1

John Daley Bendigo, Australia The Enemy of progress is the hope of a perfect plan

Benefits of rainfall collection https://permies.com/t/88043/benefits-rainfall-collection

GOOD DEBT/ BAD DEBT https://permies.com/t/179218/mortgages-good-debt-bad-debt

1

1

Aim High. Fail Small.

Repeat.

1

1

My suburban building and homesteading blog https://offgridburbia.com/

Eliot Mason wrote:Insulation and air movement are critical building functions, getting them wrong can have tremendous (and expensive) consequences.

Rockwool insulation is a great product - just be sure to have a cheap bread knife (the serrations are critical) to cut it.

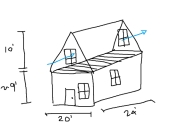

It looks like your roof framing is 2x8 or 2x10 - creating a much deeper cavity than the r23 Rockwool batt. thus as Mike says if you push the batt in betwern the framing and keep the batt flush (or nearly so) with the interior plane you will have a good 2+ inches of air space under the roof. BUT here's the rub - EACH pair of framing members creates a little "attic" - there is no way for all that air to mix and mingle and flow. Further, I see some structural blocking between the roof framing, further segmenting your "attic" into a bazillion pieces.

To create air flow the attic needs to have low-point air entry and high-point air-exits so that as the air in the attic warms it just pumps itself out. I would have used shorter blocking (flush on interior, gap on roof side). Fortunately you don't need the full height of those blocks, so get a hole saw and drill away the top (I'd think 2 x 3" holes wold do). The roof on the left of the picture is complicated because it abuts another living area; the roof on the right looks like you could have both air entry and air exits in the roof fascia (so long as you don't have blocking in the way).

There are fancy products for making a continuous vent along the peak of a roof. Turns out the same idea can be used here ... the roof sheathing would need to stop 2-3" from the wall intersection, creating a window for all the air to escape. The vent layer (a corrugated plastic sandwich thing, about 1/2" thick) would be placed at the edge of the sheathing. You would need your flashing to come down the wall to extend down the roof far enough to cover the vent. Yep, that'd do it.

And yes, others have thought of this. Excellent. For instance https://www.gaf.com/en-us/roofing-products/residential-roofing-products/ventilation-and-attic-vents/exhaust/hip-vents/cobra-hip-vent

thank you for such thorough reply, i feel like there is most definitely hope out there for the wool! what type of insulation would you do if this was your house?

1

1

Aim High. Fail Small.

Repeat.

1

1

Iterations are fine, we don't have to be perfect

My 2nd Location:Florida HardinessZone:10 AHS:10 GDD:8500 Rainfall:2in/mth winter, 8in/mth summer, Soil:Sand pH8 Flat

1

1

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

Aim High. Fail Small.

Repeat.

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

1

1

...We have cut our OSB and our blocking so we are ready for tin this weekend!! Thank you all for the information on venting, it has been such a great help.

...We have cut our OSB and our blocking so we are ready for tin this weekend!! Thank you all for the information on venting, it has been such a great help.

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

1

1

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

|

It was a tommy gun. And now this tiny ad insists on being addressed as "Tommy":

Learn Permaculture through a little hard work

https://wheaton-labs.com/bootcamp

|