"You must be the change you want to see in the world." "First they ignore you, then they laugh at you, then they fight you, then you win." --Mahatma Gandhi

"Preach the Gospel always, and if necessary, use words." --Francis of Assisi.

"Family farms work when the whole family works the farm." -- Adam Klaus

we CAN build a better world

R Scott wrote:Best addition to the double barrel stove is to run a secondary air--put a piece of 2 inch pipe from the upper bung of the burn camber over to the pipe and elbow it up into the secondary barrel. You will get a reburn and a cleaner exhaust.

R Scott wrote:Which is best really comes down to what you have for firewood. We always ran barrel stoves in the shop because they could take any scrap lumber. But they would need CONSTANT feeding if all you have is small sticks. If you have fuel that feeds in a J tube, build a J tube.

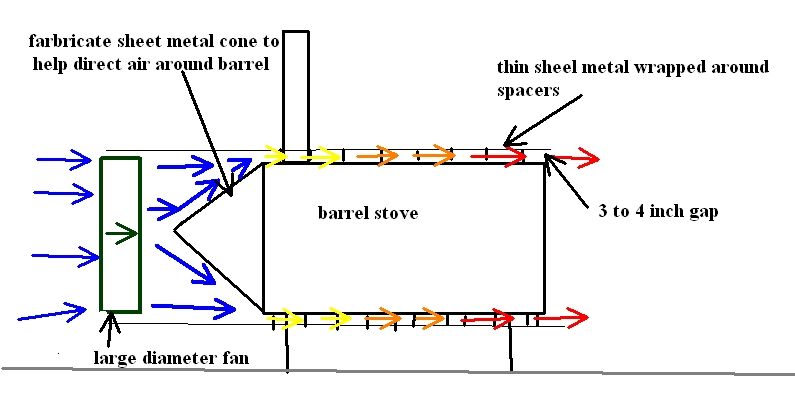

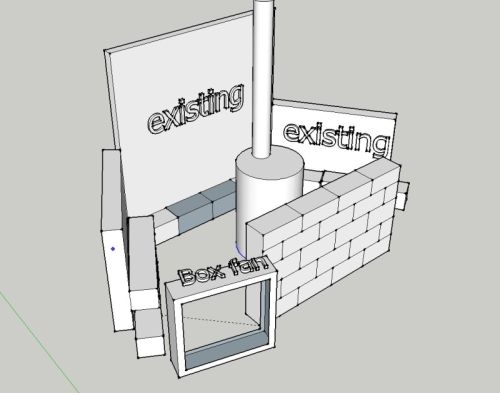

Andor Horvath wrote:

...Hope this helps...

"You must be the change you want to see in the world." "First they ignore you, then they laugh at you, then they fight you, then you win." --Mahatma Gandhi

"Preach the Gospel always, and if necessary, use words." --Francis of Assisi.

"Family farms work when the whole family works the farm." -- Adam Klaus

Good science and good theology always agree.

Life is not about saving the planet, or the economy. Life is about saving souls.

"You must be the change you want to see in the world." "First they ignore you, then they laugh at you, then they fight you, then you win." --Mahatma Gandhi

"Preach the Gospel always, and if necessary, use words." --Francis of Assisi.

"Family farms work when the whole family works the farm." -- Adam Klaus

Good science and good theology always agree.

Life is not about saving the planet, or the economy. Life is about saving souls.

R Scott wrote:B was exactly what I was describing (you are faster at drawing, too).

The up pipe needs to be long enough to prevent smokeback, but still in enough heat to light off the smoke. About where you have it pictured is about right, maybe even a little shorter. We could get the upper barrel glowing when it was running full bore. That pipe needs to be supported somehow, the barrel ends are not strong enough to hold that much.

I love fire.

I love fire.

Rich Pasto wrote:I vote for a rocket heater type since they use less fuel than a barrel stove. In a space like yours, radiant heat is king. Multiple radiant barrels would do the trick, but again with the efficiency, a secondary brick or masonry bell would store the heat longer than a steel barrel.

Need more info?

Ernie and Erica

Wood burning stoves, Rocket Mass Heaters, DIY,

Stove plans, Boat plans, General permiculture information, Arts and crafts, Fire science, Find it at www.ernieanderica.info

Matt Brannan wrote:

Option two is a 55 gal pocket rocket design.

I would want to get more heat transfer off of the exhaust if possible though, so I would be looking at trying to pipe it into a secondary barrel as well to increase the exposed surface area for heat transfer. I could possibly incorporate the barrel with the extra piping like was seen in the video for the double stack stove to get even more surface area.

Tim Southwell

www.abcacres.com

www.facebook.com/abcacres

Youtube: ABC acres

Tim Southwell

www.abcacres.com

www.facebook.com/abcacres

Youtube: ABC acres

Tim Southwell

www.abcacres.com

www.facebook.com/abcacres

Youtube: ABC acres

|

Let nothing stop you! Not even this tiny ad:

A rocket mass heater is the most sustainable way to heat a conventional home

http://woodheat.net

|