posted 13 years ago

Hi Andy,

Thanks for sharing your project - questions is what these forums are all about.

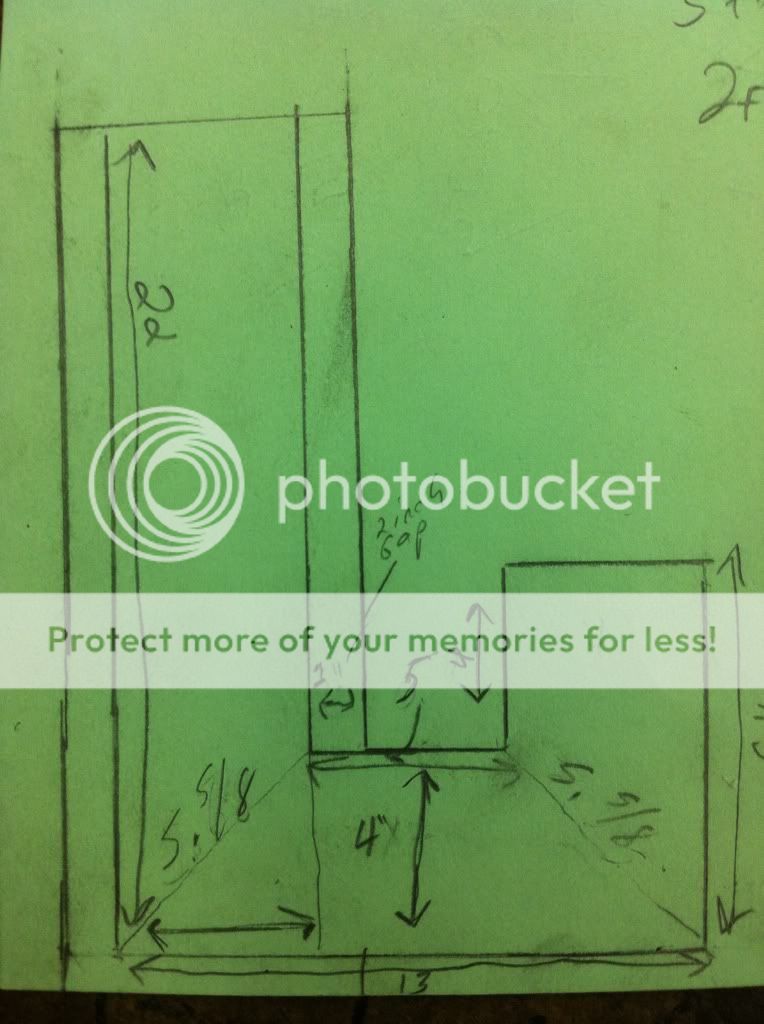

If you are thinking of doing a full rocket mass heater, vs. a cooking rocket stove, you may need to eventually move away from the 4" metal channel prototype.

6" diameter (5.5" square) is about the smallest system that can push exhaust through a downstream heat exchanger.

Masonry does a much better job of maintaining the different heat in different places that you need for it to siphon/pump. Metal is too conductive, once the system has some downstream drag to overcome. You want the feed relatively cool, the horizontal burn chamber and heat riser extremely hot, and then a relatively rapid cooling downdraft area under the barrel.

With proper insulation between the heat riser and barrel areas to maintain the temperature differential (hot up, cool down - since the 'cool' downdraft in the barrel is around 600-1000 F, the insulation has to keep the 'hot' heat riser up closer to 1800-2000 F or hotter. Some well-insulated heat risers get hot enough to forge-weld in the flame path (2800+ F). Another reason we tend to use firebrick rather than steel in this area. There also seems to be some benefit for mixing and complete combustion with the slightly rough surfaces of the brick around the flame path.

That said, I remain curious whether a shorter 4" heat exchanger, with less drag, could be made to work. It might need to be only a few feet long, and in a short building or outdoors so it can have a short 4" chimney, rather than doubling back within the thermal mass like we do with the larger systems.

Many of the 4" systems that people have built so far also had other things wrong with them, like going up and down in size or being optimistically long. So there was additional drag and stagnation to overcome.

I'd like to hear whether it works for you. I'd define 'working' as running continuously for 3-4 hours without smokeback or other problems. If you can achieve that, with a mass on a horizontal exhaust before going vertical to exit the bench/mass, it will be quite something. (If you do reach equilibrium between feed tube and heat riser, or between heat riser and barrel, it usually shows up as a distinct new smokeback problem that begins some time into the burn cycle, like 20 minutes to an hour or so after lighting the fire. Short test-firings that don't bring the whole system up to working temperatures can be deceptive.)

There's no reason the exhaust should be larger than the firebox; the gases are shrinking rather than expanding as they cool. Making them the same size seems to work well with the larger systems. But maybe it would help overcome some of the drag... just watch out for the gas stagnating and failing to flow in an oversized exhaust.

Look forward to seeing more updates,

Yours,

Erica W

1

1