"It is a miracle that curiosity survives formal education." -- Albert Einstein

Chris Burge wrote:Jamie,

I commend you for your perseverance and frugality, but I have to stop you before you go any further and point out a few things:

First of all, from your photos, it looks like you're using an awful lot of rather heavy clay slip to put the fire core together. During the first few burns, most of what is covering the inside of the burn chamber is going to spall (peel off). An easier method to stick the bricks together, and use less clay, is to mix up a bucket of thin slip (just barely pour-able; like keifer or smoothie), and then just dip each brick in the slip and set in place. This helps ensure the thinnest possible joint between the bricks and will give you the best longevity. Plus, it's much easier to keep the surface of the bricks smooth and ready to accept the next course-- even if you have to leave the project overnight.

Second, and this is very important, porcelain tile will not only be unable to handle the heat, it will practically explode. I merely placed one over the feed tube of a 4" system, to use as draft control, and after about 30 min...POP! It shattered into 6 pieces and flew all over the fireplace. Also, porcelain tile is not a very good insulator. If the bottom of your core is only made up of tile (and is sitting directly on a plastic tarp? or about 1" of fireclay/straw cob?) then I strongly recommend (if not desperately request), that you start over while you still can. At this point, if you continued your build and actually lit a fire in there, the entire bottom will shatter and begin burning the plastic long before it eventually shattered the three walls of your feed tube. Even if you had a bottom course of firebrick instead of tile, it would still get plenty hot on the underside and wind up melting the plastic and releasing all kinds of nasty fumes and toxins into your home. You would do better if you simply built directly on top of the plywood, but only if you lay down a full course of brick for the bottom of your system before laying the first course of firebrick for the bottom of your feed tube/burn tunnel/riser.

I know... after committing to a task and making progress towards a goal, the last thing you want to hear is, "start over", but I not only want you to succeed, I also want you to avoid a potentially dangerous situation. Hopefully you haven't gotten any farther than your last photo and you won't be looking at that big of a reset.

Good luck, keep at it, and keep posting pics!

Chris

Greatly appreciated.

Greatly appreciated.

"It is a miracle that curiosity survives formal education." -- Albert Einstein

Chris Burge wrote:Klinker brick will hold up for a little while, and then fracture right in half.

Common red clay brick will fracture and break down.

Most 'off-the-shelf' pavers are actually cast concrete, rather than a kiln fired-brick, and will shatter the first time you fire them.

Usually, but not always, you can get unfired clay to go back into solution, but it may take a while. Most well-established potters have a 'slip vat', (which is just a bucket or tank of water and clay) of some kind where they throw rejects and scrap pieces of clay... worth a try.

2

2

Chris Burge wrote:Klinker brick will hold up for a little while, and then fracture right in half.

Common red clay brick will fracture and break down.

Most 'off-the-shelf' pavers are actually cast concrete, rather than a kiln fired-brick, and will shatter the first time you fire them.

Usually, but not always, you can get unfired clay to go back into solution, but it may take a while. Most well-established potters have a 'slip vat', (which is just a bucket or tank of water and clay) of some kind where they throw rejects and scrap pieces of clay... worth a try.

Jamie Corne wrote:I was wondering about something.

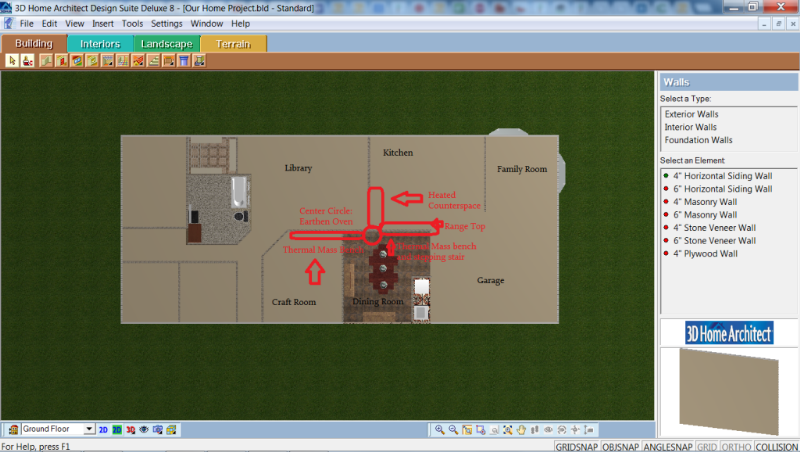

I've seen a lot of rocket heaters and mass thermal heaters where the "barrel" is exposed - and quite ugly. Then I've seen ones like in the picture below.

Does covering the barrel like that reduce the heat output?

K Nelfson wrote:

Chris Burge wrote:Klinker brick will hold up for a little while, and then fracture right in half.

Common red clay brick will fracture and break down.

Most 'off-the-shelf' pavers are actually cast concrete, rather than a kiln fired-brick, and will shatter the first time you fire them.

Usually, but not always, you can get unfired clay to go back into solution, but it may take a while. Most well-established potters have a 'slip vat', (which is just a bucket or tank of water and clay) of some kind where they throw rejects and scrap pieces of clay... worth a try.

I built a pizza oven a while back and got a lot of advice that I should use firebrick. And it's good advice but the result is expensive. If you need top quality, fine, use firebrick everywhere. If you're on a budget, use firebrick where the coals sit. But for sure avoid those concrete pavers.

Matt Carkhuff wrote:from what I have read; covering the barrel does reduce the heat ouput (at least immediate heat) and can make the top hotter. I also have seen instants of videos where they claimed the drafting was reduced (looking for the video now) and that it was less "rockety".

my thought is that with young ones it may be a good idea; just leave some of it exposed like the top 14" or so. I am still gathering parts to build my first RMH so don't take my words as gold yet...

Jeremiah wales wrote:

Jamie Corne wrote:I was wondering about something.

I've seen a lot of rocket heaters and mass thermal heaters where the "barrel" is exposed - and quite ugly. Then I've seen ones like in the picture below.

Does covering the barrel like that reduce the heat output?

I have also seen some people who have not used barrels, But they had a dome top on it instead of flat. I believe they used the end of a large Propane Tank instead of barrel. It looked a bit more custom. Wonder if it works the same being a dome instead of flat top?

This is going to be such a fun adventure

This is going to be such a fun adventure

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Jamie Corne wrote:

Matt Carkhuff wrote:from what I have read; covering the barrel does reduce the heat ouput (at least immediate heat) and can make the top hotter. I also have seen instants of videos where they claimed the drafting was reduced (looking for the video now) and that it was less "rockety".

my thought is that with young ones it may be a good idea; just leave some of it exposed like the top 14" or so. I am still gathering parts to build my first RMH so don't take my words as gold yet...

We were thinking about the kids a lot - since one of them will be only 4 in April. She loves to climb too...just our luck.

I will have to check some videos out. It's hard to find videos that go into detail on these things as I don't need so much "opinion" as I do fact...since it's our family we're dealing with here. Thank you so much for the response though - a lot of useful information and much appreciated!

"Instead of Pay It Forward I prefer Plant It Forward" ~Howard Story / "God has cared for these trees, saved them from drought, disease, avalanches, and a thousand tempests and floods. But he cannot save them from fools." ~John Muir

My Project Page

Michael Newby wrote:

Jamie Corne wrote:

Matt Carkhuff wrote:from what I have read; covering the barrel does reduce the heat ouput (at least immediate heat) and can make the top hotter. I also have seen instants of videos where they claimed the drafting was reduced (looking for the video now) and that it was less "rockety".

my thought is that with young ones it may be a good idea; just leave some of it exposed like the top 14" or so. I am still gathering parts to build my first RMH so don't take my words as gold yet...

We were thinking about the kids a lot - since one of them will be only 4 in April. She loves to climb too...just our luck.

I will have to check some videos out. It's hard to find videos that go into detail on these things as I don't need so much "opinion" as I do fact...since it's our family we're dealing with here. Thank you so much for the response though - a lot of useful information and much appreciated!

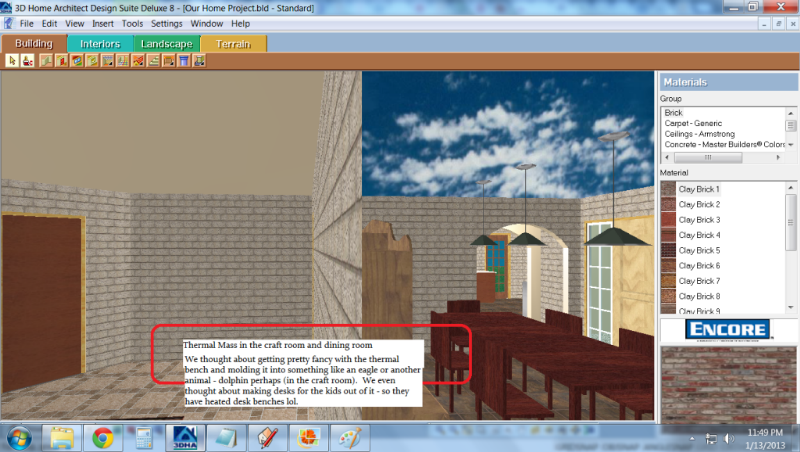

One of the main functions of the barrel is to create a difference in temperature between the hot gases in the heat riser and the cooler gases between the heat riser and the barrel. It's this difference in temperature that creates the rocketing draft - the bigger the difference in temp the better the draft, all other thing being kept constant. If you cover the barrel with cob, the stove works great while the cob is heating up until the cob gets really hot and diminishes that difference in temp.

This doesn't mean that it can't be done, just that you'll have to account for the lack of rocket effect by creating draft some other way.

Saepe Expertus, Semper Fidelis, Fratres Aeterni

De Opresso Liber

Trim sends

//BT//

Gerald O'Hara wrote:Jamie,

It isn't much colder in my area of the state than yours but at least you are 1 hour from SF. I am 4 hours away. I'd be better off going to Watertown or Fargo...LOL

One thing that caught my eye was the fact that you are using a galvanized metal for your insulation jacket. I am informed that galvanized metal gives off bad fumes when heated... so you may want to think about that before putting the barrel on and covering it with the cob. (just a thought). One day, I'll have to drive down there and see your RMH. I am in the initial stages of building rocket stoves with steel combustion chambers and chimney and using an old compressor tank for the insulation jacket. I'll let you know how that goes.

I would however like to know where you got those $.50/brick fire bricks? That might be worth a trip down that far.

Jamie Corne wrote:So we did the first "actual" burn - with everything put together and of course - things went wrong.

Without the barrel on - we get excellent draft and no smoke from the riser; but put the barrel on - and we get minimal draft and lots of smoke.

Our first thought was that the exhaust was malfunctioning.

Our second thought was that the barrel has too much height from the riser (approximately 4.5-5.0ish inches). I tried closing the feed tube down a bit to see what would happen - nothing. More smoke.

So I took the barrel off and I am reworking the base under the riser and fitting a bigger exhaust tube to the barrel.

regards, Peter

Jamie Corne wrote:I was wondering about something.

I've seen a lot of rocket heaters and mass thermal heaters where the "barrel" is exposed - and quite ugly. Then I've seen ones like in the picture below.

Does covering the barrel like that reduce the heat output?

Peter Berg wrote:

Jamie Corne wrote:So we did the first "actual" burn - with everything put together and of course - things went wrong.

Without the barrel on - we get excellent draft and no smoke from the riser; but put the barrel on - and we get minimal draft and lots of smoke.

Our first thought was that the exhaust was malfunctioning.

Our second thought was that the barrel has too much height from the riser (approximately 4.5-5.0ish inches). I tried closing the feed tube down a bit to see what would happen - nothing. More smoke.

So I took the barrel off and I am reworking the base under the riser and fitting a bigger exhaust tube to the barrel.

This exhaust from the barrel to the bench duct, the manifold, is 9 times out of 10 the source of the trouble. There's a minimum size for the top gap, but in practise no maximum at all. I've had a stove running smoothly with a top gap as large as a yard, no problems whatsoever.

Please try this forum link for a good explanation about the ins and outs of the manifold quirks.

Devon Olsen wrote:

Jamie Corne wrote:I was wondering about something.

I've seen a lot of rocket heaters and mass thermal heaters where the "barrel" is exposed - and quite ugly. Then I've seen ones like in the picture below.

Does covering the barrel like that reduce the heat output?

perhaps if you were to take this design and provide some "holes" from down near ones feet that fed to the bottom of the barrel... therefore allowing for a convection to occur around the barrel and greatly increasing your initial heat output comparative to this current design, while still keeping the designs seemingly superior long-term heat

honestly, i think thats a great design, and there is a thread on here somewhere about what to do to get rid of that ugly barrel... i think that is thinking in JUST the right direction, i absolutely love it:)

Devon Olsen wrote:well those holes should not be in any way connected to any place where it would have smoke venting, it'd simply be a serperate tube if you will that is heated by its proximity to the the hot barrel and insulator, causing the air to rise and creating a convection current

i dont see why there would be smoke unless there was a hole burned in the barrel or something...

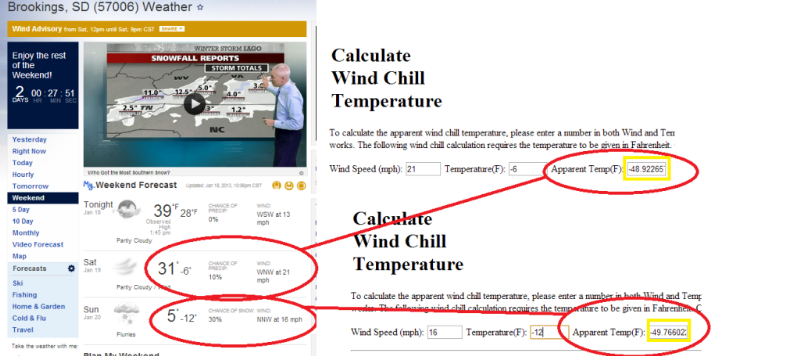

Jamie Corne wrote: Hey Gerald! You ready for the arctic freeze this weekend? You're more north so I'm going to assume it's going to get colder and windier up there...hopefully not.

As far as the tube that is galvanized - as far as I know - you have to heat zinc to 900 degrees before it gives off toxic fumes that could harm anyone - but as Ernie has stated on the forum here...it's really not that big of a problem since we are venting outside and the fumes would be so minimal...

Old habits from flying with the Navy...always say somthing when it comes to questions of safety. THere is no such thing as "Keeping your mouth shut" if safety is in question. I understand your point. Hopefully it won't get THAT hot inside your barrel.Jamie Corne wrote: I appreciate the sentiments though. Our first complete burn will be highly ventilated - just to be on the safe side. Never hurts to be safe.

My luck they won't have any left and I'll have to pay the $2.10/each. While I can do that, and currently, it is worth it to me to have them than skip that part, I do believe that going the distance with the "right bricks" is the only way to go. I (as I said above) don't like to compromise safety or anthing that would challenge my existence.Jamie Corne wrote: That fire brick that we found was at the Habitat for Humanity Restore Store in Sioux Falls. They tore down a house with a massive fireplace - and they got A LOT of the brick that was still usable. From what I understand - many Habitat Restore's across the nation have them from time to time because they tear down many different types of homes - older ones especially, which tend to have fire places. Otherwise, if you go to I-29 brick in Sioux Falls - they are 2.19 a brick - for the 3000 degree F rated bricks (used for kilns).

Jamie Corne wrote: Watertown doesn't have ANYTHING for rocket stoves. Don't waste your time there. No firebricks - no fire clay - no Vermiculite in the winter - nothing. Brookings either. Hopefully that will change soon, if we can get people to move to rocket stoves and mass thermal heaters.

It would be great to have you come on down (or over as the case might be) and see our rocket baby. Building it hasn't been without its headaches...that's for sure...but this weekend, we're planning on being awfully warm without having to make a bunch of trips out to the woodshed for logs. That...will be nice for a change. And waking up in the morning with it still being quasi-warm instead of bone-chilling cold...we can't wait

Jamie Corne wrote: I hope to have more conversations with ya - especially about the stoves that you build. Take care and if we don't talk before the storm is over - stay warm and stay safe!

Saepe Expertus, Semper Fidelis, Fratres Aeterni

De Opresso Liber

Trim sends

//BT//

Gerald O'Hara wrote:

Jamie Corne wrote: Hey Gerald! You ready for the arctic freeze this weekend? You're more north so I'm going to assume it's going to get colder and windier up there...hopefully not.

As far as the tube that is galvanized - as far as I know - you have to heat zinc to 900 degrees before it gives off toxic fumes that could harm anyone - but as Ernie has stated on the forum here...it's really not that big of a problem since we are venting outside and the fumes would be so minimal...

Well, here it is Sunday AM and it is pretty cold. We got a little fresh white dust last night but that is about it.

Old habits from flying with the Navy...always say somthing when it comes to questions of safety. THere is no such thing as "Keeping your mouth shut" if safety is in question. I understand your point. Hopefully it won't get THAT hot inside your barrel.Jamie Corne wrote: I appreciate the sentiments though. Our first complete burn will be highly ventilated - just to be on the safe side. Never hurts to be safe.

My luck they won't have any left and I'll have to pay the $2.10/each. While I can do that, and currently, it is worth it to me to have them than skip that part, I do believe that going the distance with the "right bricks" is the only way to go. I (as I said above) don't like to compromise safety or anthing that would challenge my existence.Jamie Corne wrote: That fire brick that we found was at the Habitat for Humanity Restore Store in Sioux Falls. They tore down a house with a massive fireplace - and they got A LOT of the brick that was still usable. From what I understand - many Habitat Restore's across the nation have them from time to time because they tear down many different types of homes - older ones especially, which tend to have fire places. Otherwise, if you go to I-29 brick in Sioux Falls - they are 2.19 a brick - for the 3000 degree F rated bricks (used for kilns).

Jamie Corne wrote: Watertown doesn't have ANYTHING for rocket stoves. Don't waste your time there. No firebricks - no fire clay - no Vermiculite in the winter - nothing. Brookings either. Hopefully that will change soon, if we can get people to move to rocket stoves and mass thermal heaters.

It would be great to have you come on down (or over as the case might be) and see our rocket baby. Building it hasn't been without its headaches...that's for sure...but this weekend, we're planning on being awfully warm without having to make a bunch of trips out to the woodshed for logs. That...will be nice for a change. And waking up in the morning with it still being quasi-warm instead of bone-chilling cold...we can't wait

I'll let you know when I come by that way. It may be next week since I only work two days a week. I like to plan big trips in advance and since I have to bring my dog, and feed the animals before I leave for the day, I have to do split second planning. I'll skip the stop-over in Watertown though. Since shipping is so brutally expensive out here and very unreliable, I will have to drive my truck to get these items.

Jamie Corne wrote: I hope to have more conversations with ya - especially about the stoves that you build. Take care and if we don't talk before the storm is over - stay warm and stay safe!

You can if you like send me a PM and I will be happy to discuss this with you. I shouldn't put my email address here, I guess.

I got the rocket stove outer jacket built yesterday and I only had one bag of perlite so it didn't fill up very much but now I have to grind the welds (they look awful because the N2 tank wasn't working right at first.) and weld the top on it, make some legs for it and add some spacers for the top to hold a pot. I did manage to boil water on it yesterday though. I had a tea kettle full of ice and in no time at all, I had it whistle. That was really a great feeling. Once I have the insulation in and the top on it, I should be ready to do another one and this time use an old water heater tank that I salvaged and see what I can accomplish.

More as it happens...

He said that in the Navy, "there is no such thing as accidents" and if there is a supposed "accident" it was because the person wasn't doing something while being aware.

He said that in the Navy, "there is no such thing as accidents" and if there is a supposed "accident" it was because the person wasn't doing something while being aware.

we CAN build a better world

we CAN build a better world

Andor Horvath wrote:Hi Jaime,

say, if you're a visual learner, please consider downloading Sketchup, it's free.

It will allow you to draw if you're so inclined, otherwise will allow you to download and 'fly through"/examice other peoples models...

lot's of people are using it on this and "the other" rocket discussion board.

[I have no $ interest in the software, in fact am finding frustrating to learn after using Autocad, Cadkey...]

please also check out:

builditsolar.com DIY links/advice and how to's about all things renewable energy related

onestrawrob.com a friend here in WI that is a permaculture hero

hope this helps, contact me via IM or post somehow if there are further food/energy/transportation items I can help with,

sorry to hear the "C" word

Andor

1

1

Jamie Corne wrote:Any thoughts to help me along?

regards, Peter

Peter Berg wrote:

Jamie Corne wrote:Any thoughts to help me along?

Usually, the second largest problem is the exhaust. When this stove is built inside a house or shed which is high inside and/or do consist of more than one floor there ought to be trouble. Especcially when the exhaust is leading straight outside horizontal without vertical stack. A dryer vent style exhaust is only possible inside a one storey shack equipped with an airtight roof. Read this article about the question: Is Your House a Better Chimney Than Your Chimney?

So, try to add a vertical stack, preferably reaching above the eaves. The stove will run better 99 times out of 100.

Jamie Corne wrote:It's gonna take quite a bit of energy to get that heavy smoke to to up that vertical tube...isn't it?

regards, Peter

Peter Berg wrote:

Jamie Corne wrote:It's gonna take quite a bit of energy to get that heavy smoke to to up that vertical tube...isn't it?

No, it isn't. Smoke will go up the stack when it's warmer than the outside air, that's all. Gases of higher temperature are expanded, therefore lighter and tend to rise. So this "heavy" smoke do get it's rising energy from the earth's gravity.

(Hope this is clear, I'm wrestling with the English language all the time.)

Peter Berg wrote:

Jamie Corne wrote:It's gonna take quite a bit of energy to get that heavy smoke to to up that vertical tube...isn't it?

No, it isn't. Smoke will go up the stack when it's warmer than the outside air, that's all. Gases of higher temperature are expanded, therefore lighter and tend to rise. So this "heavy" smoke do get it's rising energy from the earth's gravity.

(Hope this is clear, I'm wrestling with the English language all the time.)

Devon Olsen wrote:i see nothing non-RMH about an elevated "chimney" after all the mass

the main reason i would say it is not getting draft would be taht it has no rise at the other end, for GOOD drafting to occur the exhaust has to exit higher than the feed comes in

i would first try simply making sure that the exhaust is higher than the barrel before making it higher than the whole house

the warmed air rising out of the exhaust creates a vacuum of sorts and pulls air through the rest of the setup, if the exhaust isnt higher than the barrel (theoretically the highest point in the design) than the vacuum is weak and doesn't have enough power to really pull it through and create that rocketty goodness

in a cherokee fire pit (im calling it cherokee because i forgot the name of the tribe that did this and it sounds right to me) is basically two holes close to each other and connected at the bottom, burning your fire at the bottom of the lower hole created a draft and sucked the fire up through the second hole, which was higher up, creating less smoke and concentrating heat for cooking, also saving fuel, the fire pit doesn not work very well, if at all, if the exhaust pit is not higher than the burn pit

and i think thats your main problem here, the heat goes to the highest point, working against the draft and slowing it down, also preventing burning past that point because any oxygen that does manage to get drafted in gets smothered with CO2 due to this

1

1

Devon Olsen wrote:I should start this one by saying i havent built one myself but from my understanding of how it all works, from fire itself to draft creation etc etc

i would say that the reason you are getting any draft at all would be because the exhaust is higher than the feed tube, but i would assume it needs to be higher than the barrel to create a STRONG draft

another thing that can affect it, how much length do you have on your exhaust, to a certain extent making it longer creates a stronger vacuum when you need it, helping to create a stronger pull

for instance 20 ft of piping would be weaker than 30 ft of piping in your exhaust

another question, is all the exhaust stuff mostly airtight? i would think a small hole could greatly effect the usefulness of the draft

|

... and then the monkey grabbed this tiny ad!

Looking for cold-climate growers to join a GOOF livestream panel (Missoula)

https://permies.com/t/369111/cold-climate-growers-join-GOOF

|