32

32

Set your house in perfect order before you criticize the world

Assume that the person you are listening to might know something that you don't

Abandon Ideology

Be grateful in spite of your suffering

10

10

11

11

12

12

6

6

Phil Stevens wrote:Awesome. I'm already thinking about finding a source of quicklime so that I can try this.

Set your house in perfect order before you criticize the world

Assume that the person you are listening to might know something that you don't

Abandon Ideology

Be grateful in spite of your suffering

7

7

Fish heads fish heads roly poly fish heads

11

11

“It’s said war—war never changes. Men do, through the roads they walk. And this road—has reached its end.”

11

11

5

5

Best luck: satisfaction

Greatest curse, greed

4

4

3

3

1

1

1

1

Dan Fish wrote:A concrete breakthrough seems like a bad thing to me.

$10.00 is a donation. $1,000 is an investment, $1,000,000 is a purchase.

3

3

Steve Zoma wrote:Wow, that would really help with hydrodams if the concrete was self-healing on cracks.

I know dams have a huge amount of rebar in them, not because they need the rebar for strength per se, but to help eliminate microcracking. If concrete could be self-healing in terms of cracking, they could use a lot less rebar offsetting the higher cost of hot-mixing.

Very interesting.

$10.00 is a donation. $1,000 is an investment, $1,000,000 is a purchase.

5

5

Phil Stevens wrote: Clasts are pretty much nonexistent in aged lime putty and the process of turning into stone is slow. The restorers of heritage structures have found that mortar on the interior of thick stone walls was still plastic centuries after they were built.

My alter ego who has a potty-mouth wrote a book. Check it out here: https://www.amazon.com/Adulting-101-your-straight-succeed/dp/1732148503/ref=sr_1_5?crid=3FBIUWQCJQAPM&keywords=adulting+101&qid=1675194062&sprefix=adulting+101%2Caps%2C96&sr=8-5

6

6

2

2

1

1

There will come a day of self-sufficiency, freedom, and divine living. But for those men for whom wisdom is possible, and who do seek it, such men may truly live as gods. For men of wisdom, all things can be full of justice and mutual love. From the Wall of Oinoanda

1

1

1

1

2

2

1

1

Thomas Crow wrote:Cheers for sharing! I've always assumed that Roman Concrete was our first (so far) confirmed example of geopolymers, and this seems to confirm that.

We live on volcanic soils, so super stoked to try this out sooner rather than later.

2

2

Phil Stevens wrote:@Thekla - both processes are energy intensive but cement production requires higher temperatures and uses considerably more.

4

4

john pannacciulli wrote:Amazing...what other simple technologies have we actually lost to time?

$10.00 is a donation. $1,000 is an investment, $1,000,000 is a purchase.

4

4

3

3

2

2

Best luck: satisfaction

Greatest curse, greed

1

1

1

1

Best luck: satisfaction

Greatest curse, greed

1

1

Phil Stevens wrote:Jordan, I think the key difference here is in the mixing process. Quicklime + water = slaked lime, which over time will carbonate and turn back into limestone. If you mix the quicklime with water by itself and let it sit, you get lime putty, which is the preferred form for masonry work and plasters. Stores of lime putty have been found in old European buildings that were centuries old and still usable...it improves with age and there were even Roman laws requiring a minimum of three years of sitting after mixing before it could be used. Clasts are pretty much nonexistent in aged lime putty and the process of turning into stone is slow. The restorers of heritage structures have found that mortar on the interior of thick stone walls was still plastic centuries after they were built.

Because of this accumulated knowledge, the people researching Roman concrete assumed that lime putty was the basis of the product. The assumption up until now has been that the pozzolan was the secret sauce, but in the discovery and analysis of the clasts we're seeing that they most likely threw in some quicklime when the rest of the mix was finished. I would guess that this acted a lot like putting a handful of flour all at once into a pan of gravy that's cooking: you get a lot of lumps. So next time I have a project that fits the bill, I'll giving this a spin.

The ancient Romans used a form of lime mortar that has been found to have self-healing properties.[3] By 2014, geologist Marie Jackson and her colleagues had recreated the type of mortar used in Trajan's Market and other Roman structures such as the Pantheon and the Colosseum and studied its response to cracking.[4] The Romans mixed a particular type of volcanic ash called Pozzolane Rosse, from the Alban Hills volcano, with quicklime and water. They used it to bind together decimeter-sized chunks of tuff, an aggregate of volcanic rock.[3] As a result of pozzolanic activity as the material cured, the lime interacted with other chemicals in the mix and was replaced by crystals of a calcium aluminosilicate mineral called strätlingite. Crystals of platey strätlingite grow in the cementitious matrix of the material including the interfacial zones where cracks would tend to develop. This ongoing crystal formation holds together the mortar and the coarse aggregate, countering crack formation and resulting in a material that has lasted for 1,900 years.

“It’s said war—war never changes. Men do, through the roads they walk. And this road—has reached its end.”

3

3

Thomas Crow wrote:Cheers for sharing! I've always assumed that Roman Concrete was our first (so far) confirmed example of geopolymers, and this seems to confirm that.

We live on volcanic soils, so super stoked to try this out sooner rather than later.

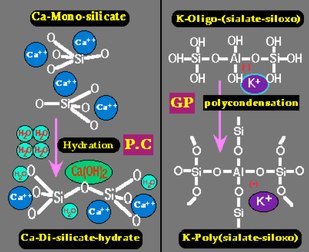

John Craig wrote:Sounds like a form of geopolymer like Davidovits has researched. An aluminosilicate rock powder or volcanic or fly ash reacted by a strong alkaline solution and then heated to form a strong polymeric structure.

“It’s said war—war never changes. Men do, through the roads they walk. And this road—has reached its end.”

2

2

John Craig wrote:Cecile:

You asked where would you get volcanic ash where you live? You don't need volcanic ash. You need a pozolan, of which volcanic ash is one kind. Pozolans are a broad category of aluminuno silicate compounds like feldspar, clays, zeolite, diatomacious earth, perlite and other aluminosilicates, many of which you can purchase at pottery supply stores. They are mixed with strong alkaline solutions of water and things like NaOh ( sodium hydroxide or lye crystals) KOh ( potasium hydroxide crystals). Both of which are used in soap making. You can also use quick lime which is also highly alkaline.

If you are interested, Google "geopolymers" or go to Steve Shelton's post on LTGS (low temperature geopolymer systems) in the rocket mass heater thread on Permies.

$10.00 is a donation. $1,000 is an investment, $1,000,000 is a purchase.

Moderator, Treatment Free Beekeepers group on Facebook.

https://www.facebook.com/groups/treatmentfreebeekeepers/

Michael Cox wrote:OK, I get that it is interesting that we might be able to reproduce "roman concrete". I'm just not sure why that is significant. It just seems like a slightly "better" form of modern concrete (and I'm not clear why it is better). It is relatively easy to design smaller projects (eg homes) without large amounts of conventional concrete anyway, and that will still be an environmentally better option than less-bad alternative form of concrete.

But where concrete gets used on massive scales, this is a non-starter. Architects won't be designing large projects around it's use because it is insufficiently consistent in it's behaviour to be guaranteed safe and predictable in it's behaviour.

At best I think this will be a niche concept for individual enthusiasts.

2

2

Michael Cox wrote:OK, I get that it is interesting that we might be able to reproduce "roman concrete". I'm just not sure why that is significant. It just seems like a slightly "better" form of modern concrete (and I'm not clear why it is better). It is relatively easy to design smaller projects (eg homes) without large amounts of conventional concrete anyway, and that will still be an environmentally better option than less-bad alternative form of concrete.

But where concrete gets used on massive scales, this is a non-starter. Architects won't be designing large projects around it's use because it is insufficiently consistent in it's behaviour to be guaranteed safe and predictable in it's behaviour.

At best I think this will be a niche concept for individual enthusiasts.

1

1

arianna higgins wrote:

Michael Cox wrote:OK, I get that it is interesting that we might be able to reproduce "roman concrete". I'm just not sure why that is significant. It just seems like a slightly "better" form of modern concrete (and I'm not clear why it is better). It is relatively easy to design smaller projects (eg homes) without large amounts of conventional concrete anyway, and that will still be an environmentally better option than less-bad alternative form of concrete.

But where concrete gets used on massive scales, this is a non-starter. Architects won't be designing large projects around it's use because it is insufficiently consistent in it's behaviour to be guaranteed safe and predictable in it's behaviour.

At best I think this will be a niche concept for individual enthusiasts.

Ever hear of the Parthenon? Roman concrete held for MILLENNIA. Our concrete only holds for maybe a century at most.

https://news.mit.edu/2023/roman-concrete-durability-lime-casts-0106

They think it's something about the calcium in seawater having self healing properties, havent done ll my reading yet.

1

1

John Craig wrote:Sounds like a form of geopolymer like Davidovits has researched. An aluminosilicate rock powder or volcanic or fly ash reacted by a strong alkaline solution and then heated to form a strong polymeric structure.

Perpetual Growth Regenerative Horticulture. Grow in peace.

Perpetual Growth Regenerative Horticulture. Grow in peace.

Perpetual Growth Regenerative Horticulture. Grow in peace.

| I agree. Here's the link: http://stoves2.com |