3

3

Dirty hands + a sweaty handkerchief = hope for the future.

7

7

6

6

6

6

.

.

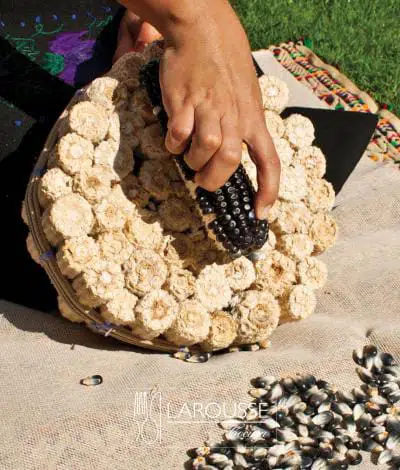

which can also be used to grind the lime-soaked corn. Though usually that is taken to the village gas-powered mill to be ground.

which can also be used to grind the lime-soaked corn. Though usually that is taken to the village gas-powered mill to be ground.pax amor et lepos in iocando

3

3

Dirty hands + a sweaty handkerchief = hope for the future.

3

3

5

5

Phil Stevens wrote:The hand cranked mills like the Victoria and the Corona are for wet nixtamalized corn. They are almost identical to a meat grinder. Trying to do dry flint corn in one of these would be torture for the contraption and the person doing the work.

I put a small amount of flint corn in with my wheat when I'm using the stone mill to make flour. This works OK as long as the ratio is at least 20:1, but trying to grind corn alone really punishes the machine so I don't do it.

pax amor et lepos in iocando

2

2

8

8

7

7

![Filename: burrs.jpg

Description: [Thumbnail for burrs.jpg]](/t/223896/a/276449/burrs.jpg)

4

4

| I agree. Here's the link: http://stoves2.com |