posted 9 years ago

To respond to the original questions:

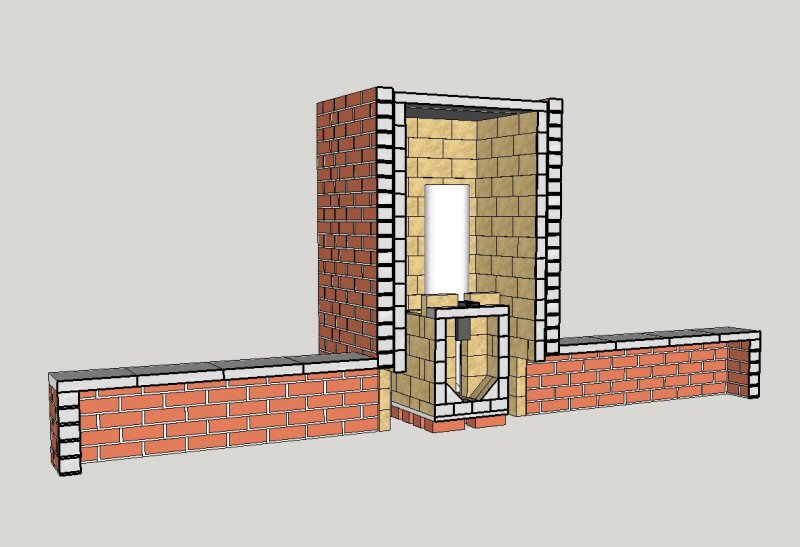

Yes, dual benches have been built. Symmetry appeals to a lot of people. There have also been multi-duct exhausts, with a true "manifold" dumping exhaust into as many as 7 or 12 separate pipes fanning out under a floor. Some of these systems re-gather at a single chimney, but others just dump the exhaust outside somewhere with no chimney advantage. These multi-flue systems might be similar to some of the k'ang or hypocaust layouts, which often had a proto-chimney or chimneys embedded in masonry walls, rather than a single chimney. It is almost impossible to achieve totally symmetrical passive flow, just as it is highly improbable to find a major river that "splits" and does not re-converge; usually, one path 'wins out' under any given conditions, and becomes stronger flowing, and therefore gathers other advantages to itself (in the case of the river, a deeper channel; in the case of the chimney, a hotter flue). In both cases, the less-traveled path tends to silt up, further reducing its advantage.

However, it's perfectly possible to artificially tinker with the flow, and even it back out to any practical degree. The old sub-floor method might involve a random brick or two placed to partially block the over-heated flue or channel. A pivot damper will give you similar control with less soot, but possibly greater impediment to cleaning unless you plan around that. There's a school of thought among masonry heater builders to avoid sliding dampers, as they jam up easier than pivot ones; all good designs will anticipate and make it easy to remove fly ash (floating small particles of mineral ash and soot).

Whether or not you will get the necessary draft advantage for the system to draw properly depends on a LOT of factors, some of which I will detail below.

The big question is whether your two chimneys will become as warm as a single chimney. The flow equation for chimney draft is given in one of the appendices of our book, and it's also available from engineeringtoolbox.com. Briefly, the temperature, area, and height of the chimney all affect draft. Area has the biggest effect, but that has to be balanced against the available heated exhaust from your particular firebox. If temperature (or more accurately relative density) becomes too cold/dense, and especially if you get below the condensation point for the water in the exhaust, your chimney(s) will draft backwards.

Yes, benches longer than 20 feet have been built. There is no hard and fast limit, and it varies with system size. A 4" system rarely has enough spare heat or draft to push exhaust through 4" channels; some 4" j-style projects have been successful using a bell and a 5" exit chimney. They are fiddly. 5" systems can have a short bench using the pipe layout. 6" systems are good up to about 20-30 feet of horizontal pipe, assuming an average chimney after that. 8" systems can push up to 30-50 feet of horizontal pipe, with a decent chimney. There have been systems built 60 feet or longer, but these often turn out to need special conditions for success (fans, downward-flowing exhaust on the lee side of a building, or some magical-seeming natural advantage with the building structure or prevailing wind direction).

There have also been systems built in the "standard" ranges (20-30 feet of pipe) that failed for "mysterious" reasons, most often relating to the building height, chimney design, etc.

If you have a 14 foot bench and a 28-foot bench, you will have dynamic draft differences due to different amounts of heat being removed (or added) by the different benches. You will always be adjusting for wind direction, indoor and outdoor temperature, etc. The total length of both benches, assuming they both have some bends in them, is pushing the limit as far as the length of pipe that one 8" firebox can typically heat. You may find it's simpler to run one bench until it's hot enough, then the other. As a consequence, the part of the room heated directly by the barrel may become unpleasantly hot before both benches are at full comfort temperature.

Another consequence, if you use dual chimneys, is that the same available heat will need to prime more surface area. (Surface area is generally a drawback: total surface exposures contribute to heat loss, friction/drag, and other costs that detract from the system's total energy budget.)

Your exit chimneys will logically be cooler than they might otherwise be, and therefore draft more slowly/poorly. I'm not sure whether you plan to size them each to the system size (for example 8" diameter), or slightly smaller so the total area is comparable to the system size (say two 6" chimneys for an 8" system). Since you may want to run either side alone, the full 8" size would make sense I think. I don't see any advantage to running two parallel 6" chimneys, and some disadvantages.

The bends where you connect the chimneys represent some added friction/turbulence/drag, so two dogleg chimneys are not going to flow as easily as a smoother Y or single chimney.

I would guess that if you run the 14' side of the bench while the 28' side is mostly shut down, there will be plenty of heat to overcome these drawbacks, and you may want to start the system this way at the beginning of the season or in any marginal conditions.

If you run both sides simultaneously under marginal operating conditions (cold start where the benches are relatively cool; unfavorable winds or outdoor temperatures; cold chimneys; etc) your exhaust may become too cold to rise, causing parts of the system to run backwards. In a linear system this would choke the fire on its own smoke (and the occupants); in this combined system there are more degrees of freedom, and perhaps one side of the bench would run backwards or stall while the other side ran; or you might see slow or delayed choking, or priming problems. You can get very weird bounce effects during chimney stall conditions even with a linear or bell system.

Under ideal operating conditions (both benches and chimneys significantly warmer than outside air, very dry firewood, house height and building draft dynamics working with you not against you) you may be able to run this system with both benches drawing simultanously. It's not outside the realm of what's possible, just beyond what's been reliable for predictable success in the past.

The added complexity might also make it a one-operator stove - something that the original builder can operate and love, but that other housemates or future tenants would struggle to operate successfully. That's because the different settings for different conditions can make it hard for a new person to learn the stove. If you always do the same thing to light the stove, and it always more-or-less works, you can have a wider range of people operate the stove successfully. Rocket stoves are already upside-down and sideways from "normal" woodstoves, and even the batch box rockets take more care to operate properly than a regular box stove. So adding complexity has costs, not just in extra parts, but also in extra difficulty for future operators.

There's also the intrinsic risk of taking a proven method and changing it - chances of failure are higher with the change than with the proven system.

(Having seen a few other dual bench prototypes, some of which were scrapped and cannibalized due to never working properly, I would say this experiment has something like a 75% chance of working worse than a single/linear bench. I have seen more that failed than succeeded, but I have seen a few that succeeded to their owners' satisfaction. If that 25% chance of a ground-breaking result is worth the effort, and you can proceed safely and have the time/energy/resources to re-do a couple times if needed, then go for it.)

The most likely benefit of this experiment that I can see would be to discover in a direct and practical manner whether a 14-foot bench, a 28-foot bench, or a 42-foot dual bench is the right size for your situation. Since you may find that the dual bench is too long, and remove one or the other extra bench for better heating balance, I would anticipate the possibility that you might only need one chimney at the end of the whole game.

If you hope for the experiment to be useful to other people not just your own situation, the most popular experiment would be a symmetrical dual bench, with the same length, pipe size, and number of turns in each wing. This configuration is interesting and relevant to more people (based on past questions), and in my opinion has a slightly higher chance of being able to balance the flow in both benches.

I do think you're wise to bring the chimneys back by the barrel (for self-priming); this is my favorite configuration, especially for longer benches.

Without getting into the building height, climate, etc, that's most of what I would consider on this project.

More important than all of the above are safety considerations. Especially with experimental systems, where the chimney temperature is less predictable, and you might end up running the firebox longer to heat both benches, I would recommend following all relevant guidelines for safety clearances, material thickness, etc. Chapter 6 in our Builder's Guide goes into detail on these. The basics are: allow at least 9" from any pipe to a combustible wall, with at least 4" of that as an air gap, and 5" masonry thickness around the bench pipes.

(The proper distance for single-wall stovepipe is 18", but this can be reduced to 9" in most areas by using good heat shielding or double-walled pipe.)

For bare metal, or masonry thinner than 5", or un-certified wood heaters of any type, some areas call for 36" to combustibles. Depending whether they recognize modified clearances, this can sometimes be reduced to 18" with good heat shielding, or as little as 12" with very excellent, double heat shielding with double air gaps. If you put any bare metal less than 12" from a combustible wall, you must heat shield that area, and check your work to ensure that the heat shielding is effective (the combustible wall's surface (paint, wood, wallpaper, plaster over wood, etc) should stay below about 160 F, or cool enough to touch).

Parts of your system will heat up more at different times, and the dynamics will change as you adjust flow and so on. So please allow excellent safety clearances so you can be surprised intellectually, rather than catastrophically.

Because the system may have irregular draft, your chances of a chimney fire are higher. The word "rocket" does not confer magical protection against chimney fires, nor does any individual element of rocket-type design, especially when tinkering and experimenting beyond well-trodden paths. The whole system has to balance itself in order to produce the smokeless fire that provides most of the safety margin against creosote buildup in the heat-exchange flues.

So again I would caution you to install the chimney(s) completely properly, according to manufacturer directions, including appropriate fasteners, fittings, insulation, shielding, etc. Minimum 3 screws per joint, for single-wall. Pipes warp with heat, and may be damaged by repeated re-configuration. Sections that go through walls, roof, chimney, or are exposed to outside air should be properly insulated class-A chimney, and note the manufacturer's recommendations about whether to add further insulation by building a 'chase' around exposed outdoor sections.

Many people under-estimate the dangers of a cool chimney, which can collect creosote when fire conditions are not optimal. When the draft of a rocket stove changes substantially, the risk of smoke and creosote is higher. And once a creosote fire starts, there may be significant damage to even the best chimney. House fires suck. Please take all available precautions to prevent a chimney fire from progressing into a house fire.

Yours,

Erica W

1

1

I'm not sure why this 20 foot number exists... and the Tipi build at the Lab seems to defy this with Paul's super long underground extension... so I'm not sure.

I'm not sure why this 20 foot number exists... and the Tipi build at the Lab seems to defy this with Paul's super long underground extension... so I'm not sure.

2

2

2

2

if you want to quote me, then QUOTE me, and there find your answer. It's disheartening to read "Chad Sentman wrote:" followed by NOT MY WORDS.

if you want to quote me, then QUOTE me, and there find your answer. It's disheartening to read "Chad Sentman wrote:" followed by NOT MY WORDS.

1

1

2

2