PIP Magazine - Issue 19: Ideas and Inspiration for a Positive Future

will be released to subscribers in:

soon!

10

10

4

4

4

4

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

2

2

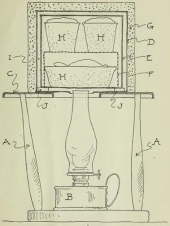

William Bronson wrote:I would favor the second iteration, for more more heat transfered to the inner oven.

I kinda doubt it will be an issue but it could lead to poor draw.

If it did, the solution is a bypass.

4

4

Benjamin Dinkel wrote:Hey Ian. That is a big bunch of soon to be ovens!

I second the juice box straw layout. More time for the heat to transfer to the oven.

But if it doesn’t work or the oven gets too small than I also think that with the efficiency of a rocket burn you can allow some heat to escape. At least you don’t blow up tons of smoke into your neighborhood.

7

7

Ian Thompson wrote:

William Bronson wrote:I would favor the second iteration, for more more heat transfered to the inner oven.

I kinda doubt it will be an issue but it could lead to poor draw.

If it did, the solution is a bypass.

Thanks for your input. What do you mean by bypass?

2

2

William Bronson wrote:

Ian Thompson wrote:

William Bronson wrote:I would favor the second iteration, for more more heat transfered to the inner oven.

I kinda doubt it will be an issue but it could lead to poor draw.

If it did, the solution is a bypass.

Thanks for your input. What do you mean by bypass?

Hmm, hard to put into words.

The second design will stratify the exhaust gasses, so only the gasses cooled by transferring their heat to the oven will sink low enough to exit the chimney flue.

This improves the efficient use of the heat , but thwarts the fastest flow of exhaust gasses.

This can be a problem that causes smoke back and inefficient burning when first starting the fire,but as the chimney flue heats up, it is unlikely to be a problem.

If your flue pipe had a tee opening into the space just above the inner container, exhaust gasses could flow almost directly into the the chimney flue.

Once the glue was hot,closing a damper located in the tee would force the gasses to satisfy.

This little added complexity l would give you the best of both designs.

5

5

3

3

|

All of the world's problems can be solved in a garden - Geoff Lawton. Tiny ad:

montana community seeking 20 people who are gardeners or want to be gardeners

https://permies.com/t/359868/montana-community-seeking-people-gardeners

|