While not a "big" system, the efficient use of exhaust gases to fuel the fire seems quite appealing for the example shown at

https://permies.com/t/19523/Charcoal-Bio-char-Production-Utilizing#281042 and at

http://www.carbon-negative.us/burners/backtap.htm

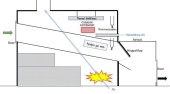

I would think you could create a brick rocket stove, and attach a half barrel to the top of the riser, and sit some spacers on the top of the riser. You then insert a slightly smaller, sealed barrel holding the biochar materials into the half barrel, ensuring that the CSA isn't limited here using those spacers. There would be an exhaust tube coming out of the lid of your biochar container, and you run that down to an intake port that feeds into the very bottom of the heat riser. Once your starter fuel gets the retort to start off gassing, that exhaust feeds back into the burn tunnel and no more fuel needs to be used to keep it burning. Once all the gasses are used up, the fire will go out.

As mentioned in those links, there's excess gasses relative to what's needed to keep the system self-fueled. Perhaps the feed pipe could split, with a smaller diameter feed to the original burn tunnel, and a second line which feeds a second heat riser. You could have a second retort filled up and waiting, and light those gasses to start a second burn while the first one is running, but that seems to be getting complicated between 2 systems linked together and timing it. I think just getting the burn to self-fuel after the initial heating helps a bunch, especially if you can fill up a 55 gallon barrel with material.

You would need to size one barrel to fit inside the other without too much spacing between them for the hot gasses to help heat up the sides of the retort. Inserting a 55 gallon barrel (or whatever size you plan to use) into another barrel, even when empty, isn't going to be easy for everyone. Having something to stand on, or burying the burn tunnel underground can help. Then you can fill up the retort, attach the lid, and then attach the exhaust pipe to the heat riser. If buried, you would have that pipe coming up out of the ground and maybe it's level with the outer barrel lip, which would make the retort lid have a much shorter attached pipe that's easier to handle. After the burn you remove the barrel full of biochar, or empty the char out first depending on the weight.

This would be a stationary system, which is an obvious downside. But I can imagine you could make the outer barrel detachable, same as the retort, so you could cover the burn tunnel and it wouldn't be taking up space. You could also tip over the outer barrel while the retort is inside of it, to pour out the biochar and you could also insert the empty retort into the outer barrel while on its side, then lift them back into standing position (instead of picking the barrel up to head height). I think I would just have a portable cover or just a tarp though to protect it from the weather, and set it up out of the way myself. This seems like it could be an affordable setup which minimizes wood waste relative to the amount of biochar, all depending on the size of barrel you can use and get a full offgassing.

. So I want to get a few opinions on a device I am building. Currently, I'm building a microwave heated BioChar kiln. Although, I don't have a lot of experience making BioChar, I wanted to know a few things about people's experiences:

. So I want to get a few opinions on a device I am building. Currently, I'm building a microwave heated BioChar kiln. Although, I don't have a lot of experience making BioChar, I wanted to know a few things about people's experiences:

1

1

1

1

1

1