"To oppose something is to maintain it" -- Ursula LeGuin

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

"To oppose something is to maintain it" -- Ursula LeGuin

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

1

1

Paramount Natural Design-Build Architect, Engineering Services, GC, LLC.

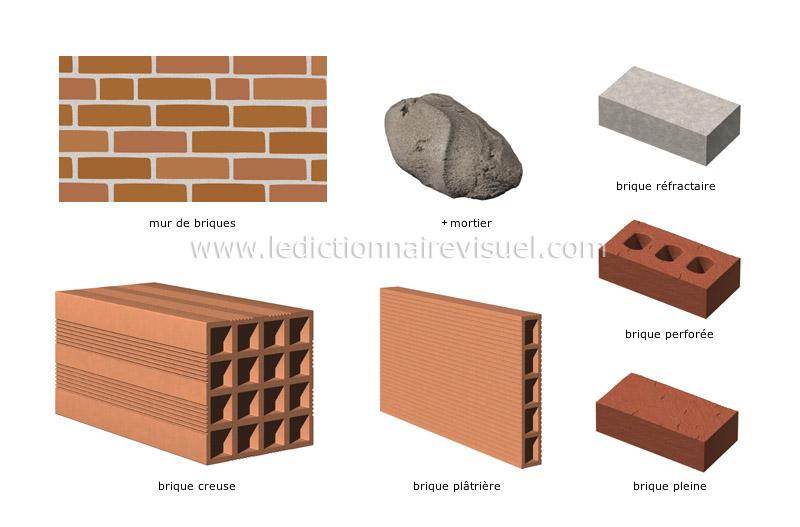

It's just, that theses blocks are "convenient". Same width as a bale on edge, load bearing, critter proof. Water proof.

It's just, that theses blocks are "convenient". Same width as a bale on edge, load bearing, critter proof. Water proof.

Furthermore where i live, there's snow, so no bales near the ground!

Furthermore where i live, there's snow, so no bales near the ground! God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

1

1

Paramount Natural Design-Build Architect, Engineering Services, GC, LLC.

2

2

1

1

Paramount Natural Design-Build Architect, Engineering Services, GC, LLC.

1

1

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

1

1

Hey, I need to get back to the breathable wall thread thanks for sticking with me on it, I need to do some more research and get back on it. It has woke up my knowledge, even reading some of the SIPs claims with MGO which are up coming up.....I hope to address and find better alternatives with it and geo-polymers. I wonder what happen to Jay, kinda miss the em

Hey, I need to get back to the breathable wall thread thanks for sticking with me on it, I need to do some more research and get back on it. It has woke up my knowledge, even reading some of the SIPs claims with MGO which are up coming up.....I hope to address and find better alternatives with it and geo-polymers. I wonder what happen to Jay, kinda miss the em  We got more Timbers coming in and I'm heading back to that 6 million $ job site Monday you can view in the Timber section. What a moisture mess! SIPs wrap.

We got more Timbers coming in and I'm heading back to that 6 million $ job site Monday you can view in the Timber section. What a moisture mess! SIPs wrap.

Love the place tho.

Love the place tho.

Paramount Natural Design-Build Architect, Engineering Services, GC, LLC.

"To oppose something is to maintain it" -- Ursula LeGuin

1

1

Paramount Natural Design-Build Architect, Engineering Services, GC, LLC.

"To oppose something is to maintain it" -- Ursula LeGuin

1

1

Paramount Natural Design-Build Architect, Engineering Services, GC, LLC.

"To oppose something is to maintain it" -- Ursula LeGuin

1

1

Paramount Natural Design-Build Architect, Engineering Services, GC, LLC.

"To oppose something is to maintain it" -- Ursula LeGuin

1

1

Paramount Natural Design-Build Architect, Engineering Services, GC, LLC.

|

When I was younger I felt like a man trapped inside a woman's body. Then I was born. My twin is a tiny ad:

permaculture bootcamp - gardening gardeners; grow the food you eat and build your own home

https://permies.com/wiki/bootcamp

|