15

15

Gardens in my mind never need water

Castles in the air never have a wet basement

Well made buildings are fractal -- equally intelligent design at every level of detail.

Bright sparks remind others that they too can dance

What I am looking for is looking for me too!

5

5

4

4

“It’s said war—war never changes. Men do, through the roads they walk. And this road—has reached its end.”

4

4

Almond Thompson wrote:Pearl, have you heard of LowTech Magazine? It is a website devoted to this kind of stuff, but they have print-on-demand books of their entire website available as well. I think you'd love it!

And have quoted it here on permies a lot

And have quoted it here on permies a lot Gardens in my mind never need water

Castles in the air never have a wet basement

Well made buildings are fractal -- equally intelligent design at every level of detail.

Bright sparks remind others that they too can dance

What I am looking for is looking for me too!

10

10

Jordan Holland wrote: Though I've never heard the part about it not unwinding, I suppose that would require a certain amount of friction in the bearings without some form of pawls or ratchet.

Gardens in my mind never need water

Castles in the air never have a wet basement

Well made buildings are fractal -- equally intelligent design at every level of detail.

Bright sparks remind others that they too can dance

What I am looking for is looking for me too!

6

6

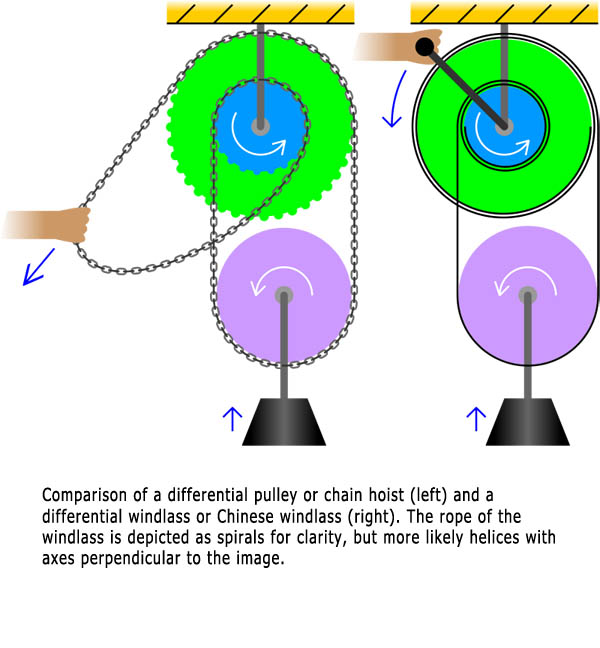

Pearl Sutton wrote:This morning's rabbithole was on differential windlasses.

Basically, by making the shaft of the windlass asymmetrical and winding the rope different ways on each section you not only need less force to lift it, but it doesn't fall if you let go of the crank, which may be the best part as far as I am concerned.

Neat tech!

$10.00 is a donation. $1,000 is an investment, $1,000,000 is a purchase.

5

5

Cécile Stelzer Johnson wrote:

That's really neat. And just in time for deer season too! We have a simple hoist and it is a pain to try and lift the deer while holding it. we don't have a rachet. It takes 2 people as someone has to prevent the slack and the deer coming back down! It seems that the less difference in radius between the 2 cylinders, the less effort it would take to lift the deer?

I am wondering if suspending the whole contraption from the ceiling will operate differently, rather than having it rest on the ground [I'm referring to the 2 As that were used as a frame] The winding cylinders would have to hang down horizontally low enough to allow the crank to rotate.

I'm really pumped to try and build something like this. Hubby should love it too!

Thanks!

4

4

Cécile Stelzer Johnson wrote: And just in time for deer season too! We have a simple hoist and it is a pain to try and lift the deer while holding it. we don't have a rachet. It takes 2 people as someone has to prevent the slack and the deer coming back down! It seems that the less difference in radius between the 2 cylinders, the less effort it would take to lift the deer?

I am wondering if suspending the whole contraption from the ceiling will operate differently, rather than having it rest on the ground [I'm referring to the 2 As that were used as a frame] The winding cylinders would have to hang down horizontally low enough to allow the crank to rotate.

Visit Redhawk's soil series: https://permies.com/wiki/redhawk-soil

How permies.com works: https://permies.com/wiki/34193/permies-works-links-threads

11

11

“It’s said war—war never changes. Men do, through the roads they walk. And this road—has reached its end.”

7

7

Jordan Holland wrote:Jay, it could be flipped around where the crank and drums were the movable part and the sheave block the stationary part.

Gardens in my mind never need water

Castles in the air never have a wet basement

Well made buildings are fractal -- equally intelligent design at every level of detail.

Bright sparks remind others that they too can dance

What I am looking for is looking for me too!

4

4

Are you thinking you'd put spindles between your legs and have a crank on each end offset by 180 degrees, or set up a short chain?Pearl Sutton wrote: So the pedals would be with the different sized spindles, and the rope goes around a stationary thing with a pulley.

I want something I can pedal that will take me up a sloped surface on wheels. Think winch on a soap box derby car.

Visit Redhawk's soil series: https://permies.com/wiki/redhawk-soil

How permies.com works: https://permies.com/wiki/34193/permies-works-links-threads

2

2

Jordan Holland wrote:Jay, it could be flipped around where the crank and drums were the movable part and the sheave block the stationary part. Here's a highly professional drawing to clearly illustrate. I added an extra sheave to make the rope wind more evenly. With the hooks on each end, you can see how it could be easily reversed to whichever way is more convenient.

7

7

Freyda Black wrote:

I love your highly professional drawing, Jordan. I can actually see how it works! However, it also makes me realize there is another problem to solve Although you have brought the crank down to within reach when you begin hoisting, it will inevitably still have to rise above the highest part of the deer, well out of reach. Is there a way to secure the cranking mechanism within reach and run the rope being lifted (as in the video of the windlass) over another pulley so that it can lift the deer (or whatever other weight) overhead without the operator having to follow it upward?

“It’s said war—war never changes. Men do, through the roads they walk. And this road—has reached its end.”

2

2

6

6

Jay Angler wrote:

Are you thinking you'd put spindles between your legs and have a crank on each end offset by 180 degrees, or set up a short chain?Pearl Sutton wrote: So the pedals would be with the different sized spindles, and the rope goes around a stationary thing with a pulley.

And wrote:

I want something I can pedal that will take me up a sloped surface on wheels. Think winch on a soap box derby car.

Theoretically, wouldn't you be able to pedal yourself back down as well? You'd need to be able to, or the "car" would be stuck at the top once you pedalled up there?

Gardens in my mind never need water

Castles in the air never have a wet basement

Well made buildings are fractal -- equally intelligent design at every level of detail.

Bright sparks remind others that they too can dance

What I am looking for is looking for me too!

7

7

Pearl Sutton wrote:

Jordan Holland wrote:Jay, it could be flipped around where the crank and drums were the movable part and the sheave block the stationary part.

That's what I want to do, why I was looking it up. I want something I can pedal that will take me up a sloped surface on wheels. Think winch on a soap box derby car. Something along those lines. So the pedals would be with the different sized spindles, and the rope goes around a stationary thing with a pulley.

Nails are sold by the pound, that makes sense.

Soluna Garden Farm -- Flower CSA -- plants, and cut flowers at our farm.

5

5

Gardens in my mind never need water

Castles in the air never have a wet basement

Well made buildings are fractal -- equally intelligent design at every level of detail.

Bright sparks remind others that they too can dance

What I am looking for is looking for me too!

5

5

Kenneth Elwell wrote:

There is a chain hoist version of this as well, a hook and double pulley at the top with the two different sized chain gears, and a smaller chain pulley at the bottom with a hook for the load. An endless loop of chain goes over one gear, down to the pulley , back up and over the smaller gear, and down again to complete the loop. the loop outside the pulleys is how you operate it, pull on one side to raise, the other side to lower.

3

3

Kenneth Elwell wrote:There is a chain hoist version of this as well, a hook and double pulley at the top with the two different sized chain gears, and a smaller chain pulley at the bottom with a hook for the load. An endless loop of chain goes over one gear, down to the pulley , back up and over the smaller gear, and down again to complete the loop. the loop outside the pulleys is how you operate it, pull on one side to raise, the other side to lower.

![Filename: chain-block.jpg

Description: [Thumbnail for chain-block.jpg]](/t/232774/a/226207/chain-block.jpg)

“It’s said war—war never changes. Men do, through the roads they walk. And this road—has reached its end.”

9

9

Gardens in my mind never need water

Castles in the air never have a wet basement

Well made buildings are fractal -- equally intelligent design at every level of detail.

Bright sparks remind others that they too can dance

What I am looking for is looking for me too!

4

4

8

8

Freyda Black wrote:Thank you for this great illustration! If I am reading it properly, the differential pulley has one continuous chain can run in grooves on the "gears" and one pulls the chain that runs to the larger gear by hand. It could be mounted on a crossbeam above and used two left I heavy object like a deer for processing.

Gardens in my mind never need water

Castles in the air never have a wet basement

Well made buildings are fractal -- equally intelligent design at every level of detail.

Bright sparks remind others that they too can dance

What I am looking for is looking for me too!

6

6

And because your a safety first type as well. If the consequence of a failure is ugly, please everyone, put safety first! There's a reason some accidents are labelled "preventable". In the case of cars, Hubby refuses to call them "accidents" and uses the term "collisions".Pearl Sutton wrote:You might want to put a secondary line just so butchering motion doesn't move it, but they hold up engines without a back up (although I'd put a backup, just because, I'm a belt and suspenders type. )

Visit Redhawk's soil series: https://permies.com/wiki/redhawk-soil

How permies.com works: https://permies.com/wiki/34193/permies-works-links-threads

1

1

Pearl Sutton wrote:

One more question. Since the gears are above one's head, can there be excess chain so that it can be reached from below? I would also assume that this arrangement would require something hook the pulley chain to in order to hold the object aloft?

Length of extra chain is irrelevant, use the amount you need. You can probably buy one sold as an engine hoist, you might check.

The load should not unwind on it's own. That's what these are made for. You might want to put a secondary line just so butchering motion doesn't move it, but they hold up engines without a back up (although I'd put a backup, just because, I'm a belt and suspenders type. )

3

3

Freyda Black wrote:

Aha, thank you, Pearl, for causing me to consider the chain hoist diagram again in relation to the length of the chain. I think I finally understand how it works. Please let me know if I am correct.

When the small cylinder (holding the hook) is at its lowest point, the chain has no slack. As you pull the chain going to the large gear, it lifts the cylinder/hook and slack is created in the chain as the smaller gear does not move. When you want to raise the hook, you would need to pull the chain running from the hook/cylinder to the small gear, not the slack part of the chain. This would necessitate reaching above the hook, unless you had an additional piece of chain or rope attached to that section of chain above the hook cyclinder. Is this correct?

“It’s said war—war never changes. Men do, through the roads they walk. And this road—has reached its end.”

1

1

It's also drawn with the "pink" moving part very close to the toothed gears to keep the picture small. If you picture the pink part 10 inches down so there's room for the hand to pull it up, along with the longer chain Jordan's describing, that might help also.Jordan Holland wrote:In the pic of the differential chain hoist that Pearl posted, the total length of the chain can be as long as you wish. Imagine the slack part hanging down where the hand is holding it, that part can hang down as long as you wish. As the load is raised, the amount of slack will actually increase and hang down lower, and vice versa.

Visit Redhawk's soil series: https://permies.com/wiki/redhawk-soil

How permies.com works: https://permies.com/wiki/34193/permies-works-links-threads

8

8

Visit Redhawk's soil series: https://permies.com/wiki/redhawk-soil

How permies.com works: https://permies.com/wiki/34193/permies-works-links-threads

4

4

Gardens in my mind never need water

Castles in the air never have a wet basement

Well made buildings are fractal -- equally intelligent design at every level of detail.

Bright sparks remind others that they too can dance

What I am looking for is looking for me too!

4

4

A friend of mine built a tripod (unless it had 4 legs... maybe) out of metal well pipe and various fittings to hold his chain hoist. He was working on old diesel engines as he's into biodiesel. I don't know if it's still assembled, but I can ask questions if it would help.Pearl Sutton wrote:Honestly, I haven't even opened it yet, as I have no way at this rental to even hook it up, there's nothing structural I trust in this place. But I will get there.

I have plans, she said darkly....

Visit Redhawk's soil series: https://permies.com/wiki/redhawk-soil

How permies.com works: https://permies.com/wiki/34193/permies-works-links-threads

5

5

:max_bytes(150000):strip_icc()/suncast-hose-reels-storage-cpljnf17524-64_1000-a8919887e15a46ccbf3e5cc1e47e7d44.jpg)

Gardens in my mind never need water

Castles in the air never have a wet basement

Well made buildings are fractal -- equally intelligent design at every level of detail.

Bright sparks remind others that they too can dance

What I am looking for is looking for me too!

3

3

Visit Redhawk's soil series: https://permies.com/wiki/redhawk-soil

How permies.com works: https://permies.com/wiki/34193/permies-works-links-threads

|

No prison can hold Chairface Chippendale. And on a totally different topic ... my stuff:

Learn Permaculture through a little hard work

https://wheaton-labs.com/bootcamp

|