1

1

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

Travis Johnson wrote:I like a 18 inch bar and chain because it is a whole lot less teeth to file, and the bar and chain are cheaper to buy. The biggest reason though is, I get far more power. I have 6 inches of less drag on a 18 inch bar over that of a 20 inch bar, (2 inches longer on the top, bottom and nose to make 6 inches) so I get more power to the chain to cut through wood. Again I so seldom cut massive trees so having more power 99% of the time makes up for the few times I have to...wait for it...cross to the other side of the log and finish the cut. Oh the horrors of that! (insert sarcasm here)

Today I will do what others won't, so tomorrow I can do what others can't.

Will Meginley wrote:

Kate Downham wrote:What is the ideal way to maintain and use a chainsaw for firewood to minimise having to replace parts?

Back to the original question: Having to go get more gas today reminded me of a couple items that hadn't been brought up yet.

Most "gasoline" sold in the United States has 10-15% ethanol content. Leaving out the fact that current technology requires 1.25 gallons of gasoline to produce 1 gallon of ethanol, it's really bad for your saw. It gums up your carburetor and erodes plastic fuel lines. If you're trying to limit repair needs, use only non-ethanol gasoline in chainsaws - and other gas powered equipment. It can be hard to find. The nearest station from me that sells it is 45 minutes away so I always take a jerry can and grab five gallons at a time to limit the amount of driving involved. Often, if a station has it, only the premium grade fuel will be non-ethanol. Near the coast it's often labeled as "boat fuel" or "recreation fuel." If you don't know of a station near you, you can try pure-gas.org. If worst comes to absolute worst, most saw shops sell a product called "TRUFUEL" that's pre-mixed 50:1 non-ethanol gasoline. It's a colossal rip-off though - usually costs about 20 bucks a gallon.

Along the same lines, if you're going to store your chainsaw for more than a handful of days before the next use, purge it of fuel. Pure gasoline will also erode fuel lines over time, just not as fast as ethanol. The less you have gas in the fuel lines, the longer that will take. Gasoline with additives can also evaporate and leave residue in the carburetor. Some of the tubes in a chainsaw carburetor are only the width of a human hair, so they don't take much to gunk up. To purge the saw: use a funnel to empty the contents of the fuel tank into your spare fuel container. Then start the saw and let it run until it dies. This shouldn't take more than a few seconds.

Sourdough Without Fail Natural Small Batch Cheesemaking A Year in an Off-Grid Kitchen Backyard Dairy Goats My website @NourishingPermaculture @KateDownham

Kate Downham wrote:I hadn't heard of this before. I am in Australia, normal car fuel here is 92%, and that's what we use for the chainsaw. There is usually a 95% option too - would this 95% fuel be worth it?

Today I will do what others won't, so tomorrow I can do what others can't.

Will Meginley wrote:

Travis Johnson wrote:I like a 18 inch bar and chain because it is a whole lot less teeth to file, and the bar and chain are cheaper to buy. The biggest reason though is, I get far more power. I have 6 inches of less drag on a 18 inch bar over that of a 20 inch bar, (2 inches longer on the top, bottom and nose to make 6 inches) so I get more power to the chain to cut through wood. Again I so seldom cut massive trees so having more power 99% of the time makes up for the few times I have to...wait for it...cross to the other side of the log and finish the cut. Oh the horrors of that! (insert sarcasm here)

A smaller bar results in fuel savings also. I have both an 18 and a 20 inch bar for my saw. The same tank of gas gets me 45 minutes of saw time with the 20" or an hour with the 18." Fifteen extra minutes for giving up two inches of cutting length.

One situation where having a larger bar is nice, though, is if you're doing a lot of thinning (cutting small trees and brush from around and under larger trees). The extra bar length means you don't have to bend over as far, which really saves your back over the course of a long day. In the past, I've been known to slap a 24 inch bar onto an 036 at work if I knew I was going to be out thinning all day. I wouldn't use that setup to cut anything over about twelve inches, though. WAY underpowered. But eight inches was usually the upper limit of our prescriptions, anyway, and it saved my back. Burns more gas. Like always, there's a trade off somewhere.

Mike Jay wrote:Thanks again Travis! I just have two white pines that I need to cut down.

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

Mike Jay wrote:It's good to know that white pine is easier on the chainsaw mill.

My buddy has a sawmill and when he cuts white pine he puts dishwashing soap along with water in the blade lube drip system. He cut 1200 board feet of pine for me and I didn't see any big pitch problems. That was on winter cut pine and we were sawing in mid summer (if it matters).

2

2

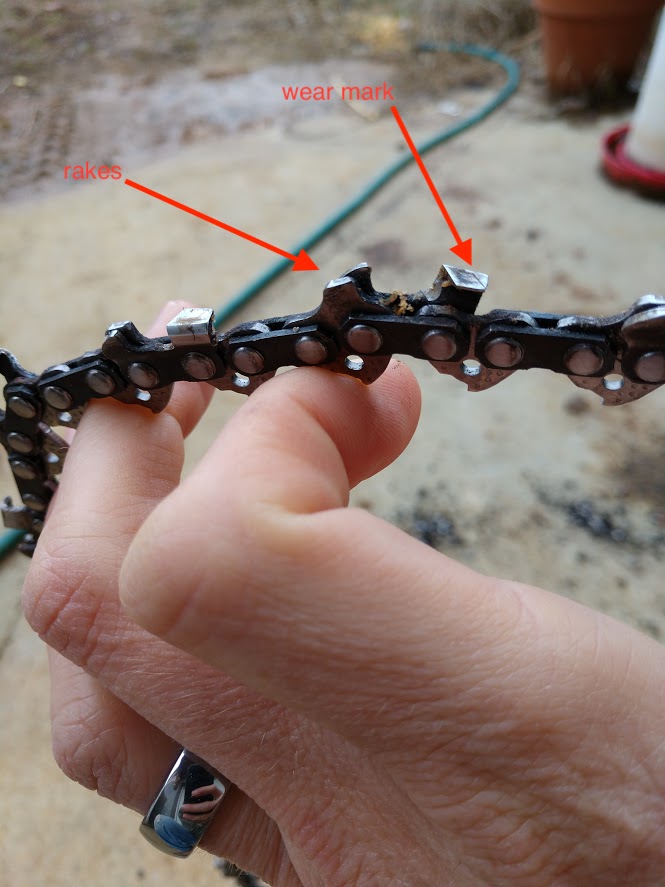

![Filename: IMG_20190723_151032100.jpg

Description: [Thumbnail for IMG_20190723_151032100.jpg]](/t/116619/a/83978/IMG_20190723_151032100.jpg)

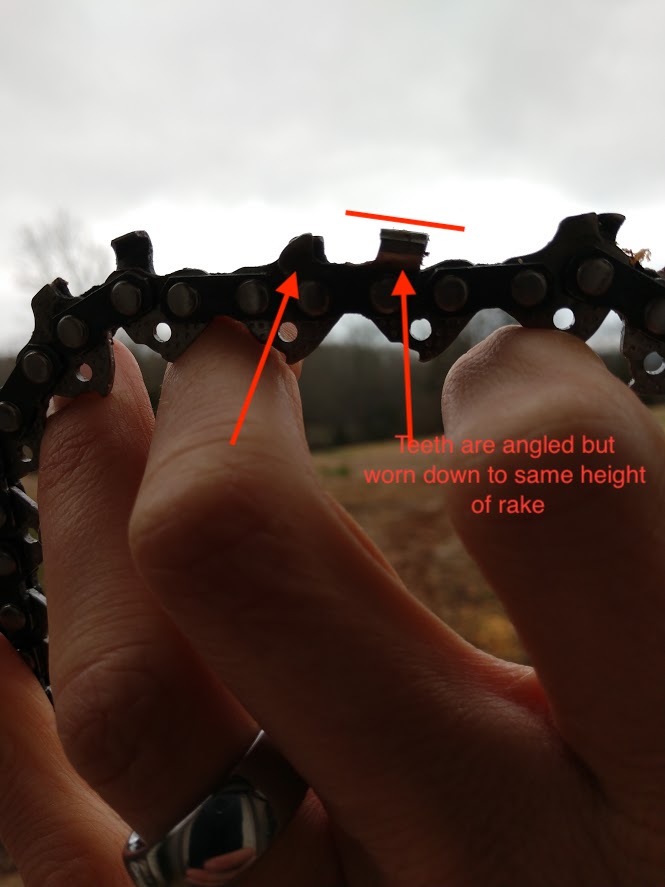

![Filename: IMG_20190725_133358247_HDR.jpg

Description: [Thumbnail for IMG_20190725_133358247_HDR.jpg]](/t/116619/a/83979/IMG_20190725_133358247_HDR.jpg)

"Study books and observe nature; if they do not agree, throw away the books." ~ William A. Albrecht

1

1

"Study books and observe nature; if they do not agree, throw away the books." ~ William A. Albrecht

2

2

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

Sourdough Without Fail Natural Small Batch Cheesemaking A Year in an Off-Grid Kitchen Backyard Dairy Goats My website @NourishingPermaculture @KateDownham

4

4

“Uncertainty is an uncomfortable position. But certainty is an absurd one.”

― Voltaire