1

1

Michael Jacobsen

1

1

Michael Jacobsen

7

7

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

2

2

3

3

2

2

Failure is a sign of activity and learning. It had nothing to do with under achievement

I never want to have a team member who has never failed - They are not doing!! 👍

1

1

thomas rubino wrote:Hi Michael;

We do not normally encourage folks to try heating water with a rocket stove.

The potential for water to flash to steam and implode/explode the water lines is high.

Having said that.

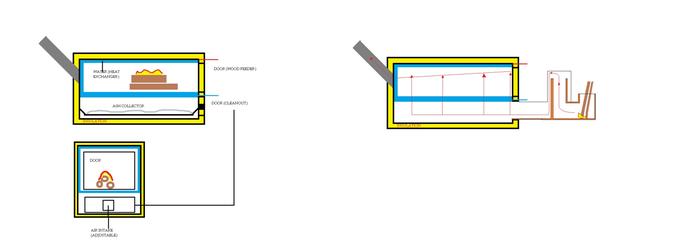

Consider heating a tank of water with a batch box RMH inside a brick bell, it is a proven safe system.

Pumping that water into other tanks would be safe and easy.

Michael Jacobsen

1

1

Steve Zoma wrote:I can think of a few quick problems you might have...

With a design that is completely dependent on flow of water.

Michael Jacobsen

2

2

Paul Fookes wrote:I have been watching this thread for a while. Steve's notes of caution are well founded.

Michael Jacobsen

I had a very smart plumber who said anything mechanical can break. The Shepherds crook eliminates the need for a mechanical relief valve. Our solar panels are 50% recommended and the water can boil during summer.

1

1

Invasive plants are Earth's way of insisting we notice her medicines. Stephen Herrod Buhner

Everyone learns what works by learning what doesn't work. Stephen Herrod Buhner

1

1

Anne Miller wrote:Something that might be a consideration is using the water as a mass and running it under the floor.

I have only read about this concept though I like it.

Michael Jacobsen

2

2

1

1

Glenn Herbert wrote:One important factor that I have not seen mentioned is that you are putting a heat exchanger around the burn tunnel/heat riser area.

Michael Jacobsen

Iterations are fine, we don't have to be perfect

My 2nd Location:Florida HardinessZone:10 AHS:10 GDD:8500 Rainfall:2in/mth winter, 8in/mth summer, Soil:Sand pH8 Flat

|

Today's lesson is that you can't wear a jetpack AND a cape. I should have read this tiny ad:

Learn Permaculture through a little hard work

https://wheaton-labs.com/bootcamp

|