15

15

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

8

8

Silence is Golden

For all your RMH needs:

dragontechrmh.com

7

7

Gerry Parent wrote:While helping Thomas to build the air frame for the shorty door today, when we got to laying out the air channels (particularly the main air inlet at the bottom) we wondered why it has two horizontal square tubes attached to each other which share the main air opening instead of just one.

The only thing we could think of is that maybe Peter wanted to give the door more surface area to seal against that one piece just wasn't going to be enough to provide.

regards, Peter

5

5

Peter van den Berg wrote:That reason you mention above was following from a couple of others: the first being to provide enough space for the air stream to split and going through two 90º bends, both left and right. The tube on its own proved to be too restrictive, as long ago as for the DSR2 prototype. The second reason was how to provide a threshold for the ashes to stay in the firebox. And last but not least room for the door seal. The air inlet in the lower part of the door, as shown in the pictures of DSR2, DSR3 and Shorty alike proved to be unpractical in the long run.

So far, the air frame looks good, please go on!

Silence is Golden

For all your RMH needs:

dragontechrmh.com

4

4

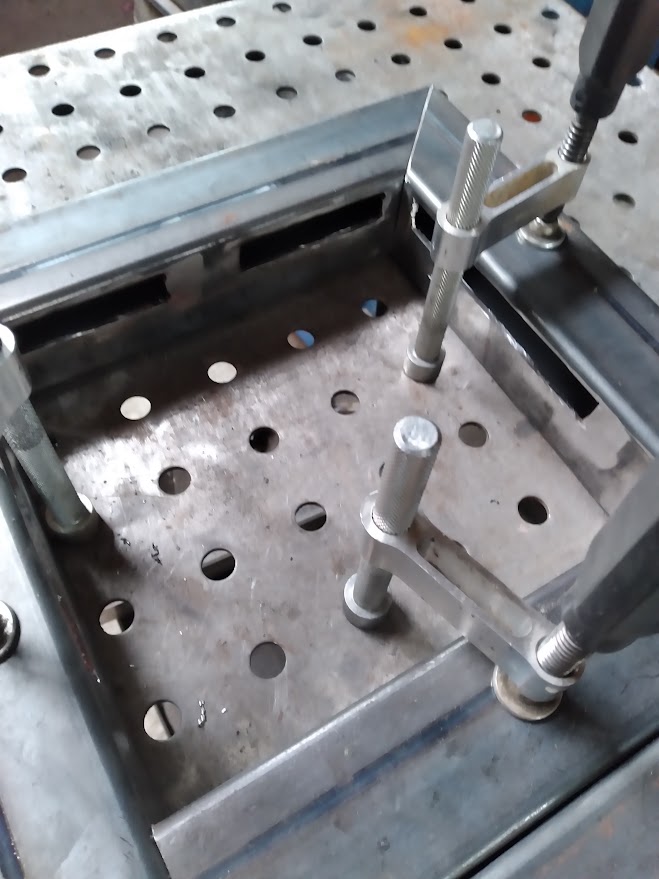

![Filename: 20240509_104334.jpg

Description: [Thumbnail for 20240509_104334.jpg]](/t/254292/a/238780/20240509_104334.jpg)

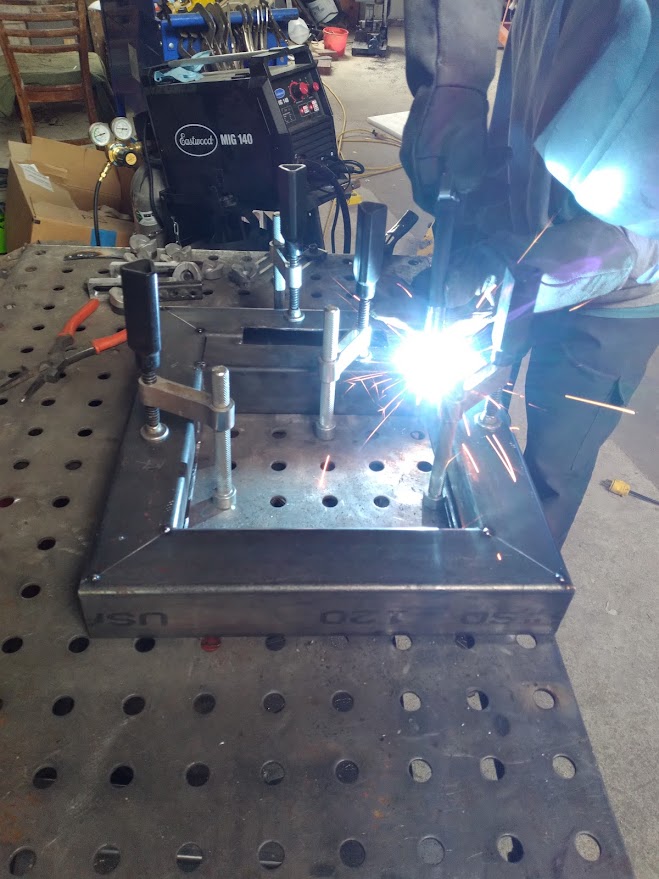

![Filename: 20240509_104330.jpg

Description: [Thumbnail for 20240509_104330.jpg]](/t/254292/a/238781/20240509_104330.jpg)

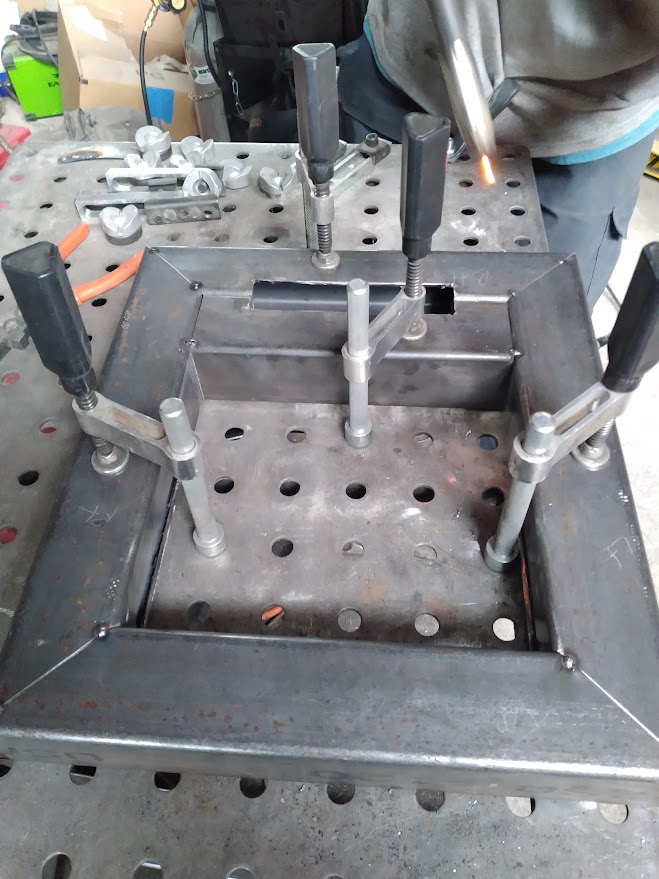

![Filename: 20240509_104350.jpg

Description: [Thumbnail for 20240509_104350.jpg]](/t/254292/a/238782/20240509_104350.jpg)

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

7

7

Rocket surgeon and soil builder... healthy plants are all about the soil.

- My 6" Batch Rocket specs and materials list: https://permies.com/t/248275/Batch-Rocket-Double-Skin-Bell

- Batch Rocket detailed build thread with Q&A: https://permies.com/t/238503/Batch-Rocket-Build

6

6

Peter van den Berg wrote:

That reason you mention above was following from a couple of others: the first being to provide enough space for the air stream to split and going through two 90º bends, both left and right. The tube on its own proved to be too restrictive, as long ago as for the DSR2 prototype. The second reason was how to provide a threshold for the ashes to stay in the firebox. And last but not least room for the door seal. The air inlet in the lower part of the door, as shown in the pictures of DSR2, DSR3 and Shorty alike proved to be unpractical in the long run.

So far, the air frame looks good, please go on!

5

5

Scott Weinberg wrote:I enclosed a few photos in case there are some not sure what this frame looks like. ( the door is off and not shown) Just the frame and then some airflow paths drawn in.

regards, Peter

5

5

Glenn Littman wrote:Following along with your process and thinking about building my door this summer. For the air slots on the inside of the frame I'm thinking it may be easier to drill 3/4" holes for the ends of the slots and then cut with the angle grinder. Any thoughts on this approach since you have experience cutting with the jig saw? I'm pretty sure I have a 3/4" drill bit.

Silence is Golden

For all your RMH needs:

dragontechrmh.com

|

And that's when I realized I wasn't wearing any pants. Maybe this tiny ad has pants:

Looking for cold-climate growers to join a GOOF livestream panel (Missoula)

https://permies.com/t/369111/cold-climate-growers-join-GOOF

|