2

2

2

2

Cerbu Ulea wrote:very helpful, thanks . A flying threshold it's ok? I mean a 2-3 centimeters high bar of thin fire brick just under the front of the roof , So when the door is open the roof does not open directly to the room, I had it in previous build and reduces smells when refueling

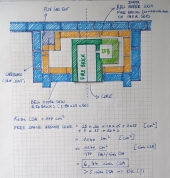

The front of my core will look like that, 36/44 cm measures the contour for the frame

2

2

3

3

3

3

Cerbu Ulea wrote:hello, today I want to start the brick work, I will not use a tension frame for the core , for the airframe it is ok 4 studs trough the front wall? a square frame on the inside of the wall around the core would hold them

regards, Peter

4

4

6

6

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

5

5

6

6

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

5

5

7

7

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

6

6

7

7

8

8

7

7

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

4

4

6

6

Cerbu Ulea wrote:hello, how do you reckon I should lay core's base on the plate? clay&sand , superwool?

regards, Peter

2

2

![Filename: od3Q28K.png

Description: [Thumbnail for od3Q28K.png]](/t/286849/a/273252/od3Q28K.png)

4

4

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

5

5

4

4

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

4

4

6

6

regards, Peter

4

4

5

5

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

8

8

Cerbu Ulea wrote:I can grind two sides to 50 with ease , the part above the port I can change the brick piece ; should I grind at an angle to make the enlargement slower?

Cerbu Ulea wrote:Another question please , seeing riser's big thickness, even if covered in superwool what is the expected time to kick in to a good burn rate?

regards, Peter

5

5

8

8

Cerbu Ulea wrote:...than if you wont mind i'll ask what to do with the air intake after the fire is out , but coals still red, cooking inside the core I saw you wrote is a good option, maybe you have a testo diagram of the embers faze

regards, Peter

6

6

7

7

Cerbu Ulea wrote:but being hot I suppose a bread would cook on the extinct coals, i'll try , it is not a must

regards, Peter

6

6

8

8

Cerbu Ulea wrote:I'm splitting an oak and a horse chestnut tree I was given this January, would this piece be too big ?

regards, Peter

6

6

8

8

Cerbu Ulea wrote:nice , mine being a sidewinder affects somehow the position of the top lighting pattern , or the position of the air slits?

regards, Peter

8

8

5

5

7

7

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

5

5

7

7

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

5

5

|

Remember to always leap before you look. But always take the time to smell the tiny ads:

Play Your Way to a Sustainable Lifestyle: Uncover Permaculture Principles with Each Card

https://gardener-gift.com/

|