9

9

1

1

Permaculture...picking the lock back to Eden since 1978.

Pics of my Forest Garden

3

3

1

1

Life on a farm is a school of patience; you can't hurry the crops or make an ox in two days.

Henri Alain

'Theoretically this level of creeping Orwellian dynamics should ramp up our awareness, but what happens instead is that each alert becomes less and less effective because we're incredibly stupid.' - Jerry Holkins

2

2

2

2

1

1

'Theoretically this level of creeping Orwellian dynamics should ramp up our awareness, but what happens instead is that each alert becomes less and less effective because we're incredibly stupid.' - Jerry Holkins

2

2

"The rule of no realm is mine. But all worthy things that are in peril as the world now stands, these are my care. And for my part, I shall not wholly fail in my task if anything that passes through this night can still grow fairer or bear fruit and flower again in days to come. For I too am a steward. Did you not know?" Gandolf

2

2

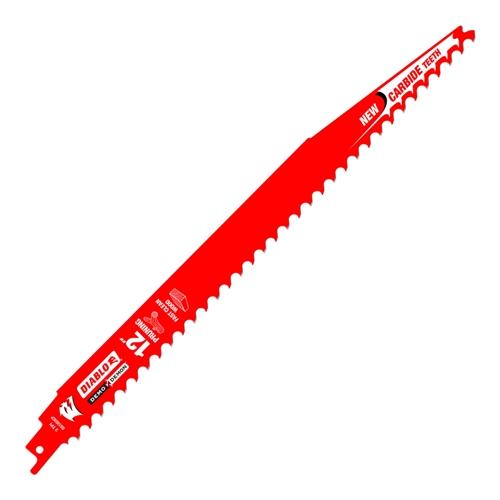

Dale Hodgins wrote:I used some of the carbide metal cutting blades today and they were a colossal disappointment. Tried them on an old hot water heating system. The teeth came off relatively quickly when I tried to cut those pipes and steel gas line. I thought it might just be that those were somehow hardened materials, so I tried another blade on rebar with the same effect. So perhaps the Diablo carbide metal cutting blades are useful for cutting mild steel I-beams, but they are certainly not suitable for anything I've tried so far. Perhaps the teeth did stay sharp, but since they got knocked off, those sharp little bits are somewhere on the floor.

As for them lasting 20 times longer, I used a standard Milwaukee hacksaw blade on the same rebar and got more cuts out of it before it went dull. I will get some pictures if I can find those blades.

The video shows a nice smooth cuts being made. I'm often in places where there's lots of bouncing, until the blade scores the material. Perhaps it's the bouncing that the teeth can't take. I am never in a shop type situation, where I could prevent that. I don't know that I've ever been so completely disappointed with a product that held so much promise.

Life on a farm is a school of patience; you can't hurry the crops or make an ox in two days.

Henri Alain

Dale Hodgins wrote:I bought two nine inch blades and one 12. The only time I ever expect to use the 12in, would be if I'm cutting a large stump or if I have to make a beam cut in a difficult location. I think most of the time that extra length would just get in the way.

For pruning of fruit trees and other small maintenance, the six inch blade would probably be better.

The 9-inch was perfect for the stuff I did yesterday, since I had to cut some seven in stumps and some 8in posts.

Diablo blades are usually quite strong and they don't break off very easily at the point where they enter the power unit. But a big long blade that's flopping around a lot, might be more prone to metal fatigue at that point. Most DeWalt blades that I have used, broke off at that point before the teeth were dull, and DeWalt go dull easily. I never by low-quality crap like that, but sometimes people leave them behind, so I use them up. Better than tin foil, and perfectly suitable for cutting butter or jello :-)

Nails are sold by the pound, that makes sense.

Soluna Garden Farm -- Flower CSA -- plants, and cut flowers at our farm.

Check out my podcast! https://allaroundgrowth.buzzsprout.com/ ~ Community Group Chat: https://t.me/allaroundgrowth

1

1

Dale Hodgins wrote:We managed to cut those steel and wood beams. It took about 5 minutes per side. It was necessary to have a 6 in space between the portion of the house being lifted and the portion that will be left behind. So 10 minutes for each beam of actual cut time. And at least another five minutes of monkeying with blades and moving the ladder Etc.

We ended up using jack posts, so that it didn't have to be done while the crew waited.

The Diablo carbide metal cutting blades might be slightly faster than the thinner Milwaukee blades. After making two cuts, the carbide blade was still in good shape. But then it broke, so ultimately didn't cut any further than the Milwaukee metal cutting blade. It was a difficult spot, where there was some bending at the point where the blade inserts into the Sawzall. In a shop situation, I'm sure the carbide blade would last much longer, since the teeth on the Broken Blade are still in perfect condition.

Father of two, DIYer and a Philomath @ TheSawingYard

4

4

|

Quick! Before anybody notices! Cover it up with this tiny ad:

Learn Permaculture through a little hard work

https://wheaton-labs.com/bootcamp

|