15

15

My journal documenting my time living on the Stone Baerm Homestead in summer 2021: https://permies.com/t/160807/Stone-Baerm-Adventures

10

10

My journal documenting my time living on the Stone Baerm Homestead in summer 2021: https://permies.com/t/160807/Stone-Baerm-Adventures

1

1

No man is an island.

4

4

My journal documenting my time living on the Stone Baerm Homestead in summer 2021: https://permies.com/t/160807/Stone-Baerm-Adventures

9

9

My journal documenting my time living on the Stone Baerm Homestead in summer 2021: https://permies.com/t/160807/Stone-Baerm-Adventures

2

2

John Daley Bendigo, Australia The Enemy of progress is the hope of a perfect plan

Benefits of rainfall collection https://permies.com/t/88043/benefits-rainfall-collection

GOOD DEBT/ BAD DEBT https://permies.com/t/179218/mortgages-good-debt-bad-debt

1

1

John C Daley wrote:I assume the standing position with the long handle is more comfortable than the hand and arm system.

My journal documenting my time living on the Stone Baerm Homestead in summer 2021: https://permies.com/t/160807/Stone-Baerm-Adventures

1

1

John Daley Bendigo, Australia The Enemy of progress is the hope of a perfect plan

Benefits of rainfall collection https://permies.com/t/88043/benefits-rainfall-collection

GOOD DEBT/ BAD DEBT https://permies.com/t/179218/mortgages-good-debt-bad-debt

1

1

John C Daley wrote:Would a simple knob at the top work, I have a road tamping tool with one and it helps.

My journal documenting my time living on the Stone Baerm Homestead in summer 2021: https://permies.com/t/160807/Stone-Baerm-Adventures

1

1

Zone 6, 45 inches precipitation, hard clay soil

2

2

May Lotito wrote:

How heavy is the sledge hammer? I use my sledge hammer for crushing stuffs too. It is heavy at 8 # so I put things on a 1 ft tall tree stump, sometimes with a cardboard box for containing. With this height, I am able tobstand straight up with both hands holding the handle and smash with a up and down motion. It's not hurting my back or wrist this way. I guess if the hammer is light enough with one hand, a knob will work. Otherwise, maybe weld a horizontal bar on top for both hands to hold?

My journal documenting my time living on the Stone Baerm Homestead in summer 2021: https://permies.com/t/160807/Stone-Baerm-Adventures

1

1

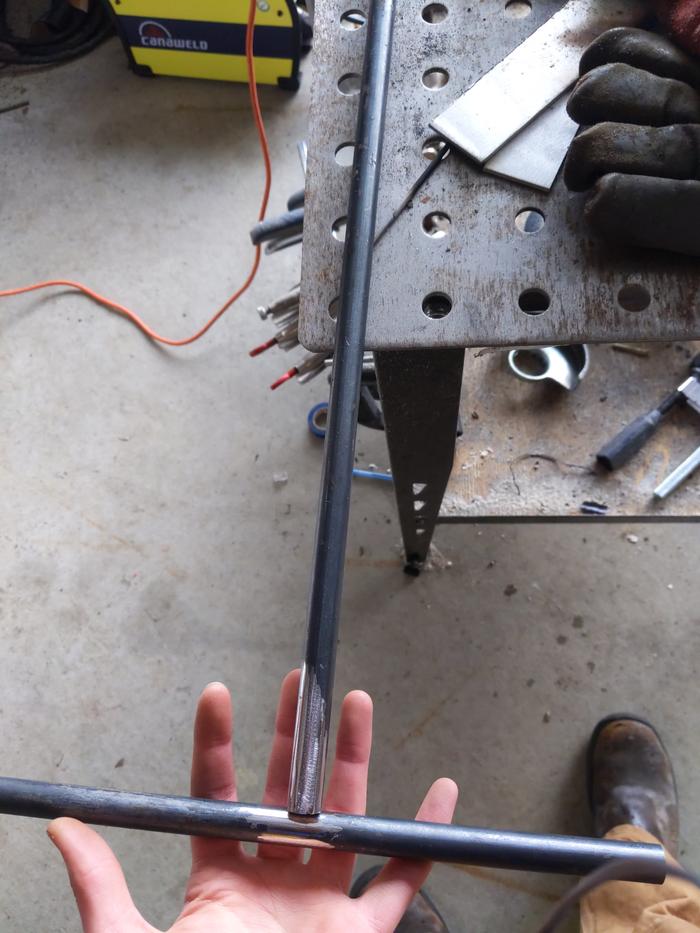

Cam Haslehurst wrote:This tool has been a while in the making, but I'm just about done making it. The idea came from struggling to crush bones and eggshells in large quantities. An 8lb sledge was used originally, but it got tiring to keep a good grip on it. So I'm basically adding a handle to make things much easier to grip. I guess you could say it's one part of a giant mortar and pestle. It's all from scrap, so the first little while was spent hunting around the property for handle materials. Once I found a tube that would work, I cleaned it, measured, and cut it. I also cleaned the rust off the hammer head. In addition I ground down one end of the head down to bare steel to make sure I got a good connection for the welding. It takes some extra time, but makes the weld both easier to do and it ends up being stronger. Today I welded them together, succesfully I might add. I did several small beads to avoid burning through, and so I could rotate the tool. It was an awkward set up but it ended up working well.

Now to just add the rectangular cap to seal stuff in and it will be ready to get crushin'.

Passionate advocate for living at a human scale and pace.

Help me grow the permaculture presence in Indiana https://permies.com/t/243107

Concise Guide to Permies' Publishing Standards: https://permies.com/wiki/220744

3

3

Jim Garlits wrote:You made the analogy of a mortar and pestle. I think that is apt. What if you added a cylindrical steel pestle into which the mortar fit pretty snugly? Could even put a small sliding door at the bottom to clean out the finer contents at the bottom when you're done smashing. I think that the increased pressure per square inch might yield a smaller, finer output.

) Notice my very expensive "chop saw". This won't cut anything thicker than 3/4" thick or so, and it is very slow. But it was only $25, as opposed to $300+ for an actual chop saw. For my at-home messing about purposes it is perfect.

) Notice my very expensive "chop saw". This won't cut anything thicker than 3/4" thick or so, and it is very slow. But it was only $25, as opposed to $300+ for an actual chop saw. For my at-home messing about purposes it is perfect.

But it just means that after welding, I did a small weld on where my other welds ended. Often, a little divot is left at the end of a weld.

But it just means that after welding, I did a small weld on where my other welds ended. Often, a little divot is left at the end of a weld.

My journal documenting my time living on the Stone Baerm Homestead in summer 2021: https://permies.com/t/160807/Stone-Baerm-Adventures

2

2

"The best fertilizer is the gardener's shadow"

Anonymous Agrarian Blog

3

3

This happened a couple times to me when I was living on the homestead.

This happened a couple times to me when I was living on the homestead.

My journal documenting my time living on the Stone Baerm Homestead in summer 2021: https://permies.com/t/160807/Stone-Baerm-Adventures

2

2

“It’s said war—war never changes. Men do, through the roads they walk. And this road—has reached its end.”

Cam Haslehurst wrote:

Jim Garlits wrote:You made the analogy of a mortar and pestle. I think that is apt. What if you added a cylindrical steel pestle into which the mortar fit pretty snugly? Could even put a small sliding door at the bottom to clean out the finer contents at the bottom when you're done smashing. I think that the increased pressure per square inch might yield a smaller, finer output.

Excellent idea Jim. Potentially a properly dimensioned pipe welded or bolted to some flatbar that one could stand on to hold it steady.

Passionate advocate for living at a human scale and pace.

Help me grow the permaculture presence in Indiana https://permies.com/t/243107

Concise Guide to Permies' Publishing Standards: https://permies.com/wiki/220744

|

"To do good, you actually have to do something." -- Yvon Chouinard

Learn Permaculture through a little hard work

https://wheaton-labs.com/bootcamp

|