Small Sustainable housing: Tiny Houses, Tiny Living: TheTinyLife.com

Check out my Primal Prepper blog where I talk about permaculture, prepping, and the primal lifestyle... all the time!

Small Sustainable housing: Tiny Houses, Tiny Living: TheTinyLife.com

2

2

Small Sustainable housing: Tiny Houses, Tiny Living: TheTinyLife.com

Check out my Primal Prepper blog where I talk about permaculture, prepping, and the primal lifestyle... all the time!

1

1

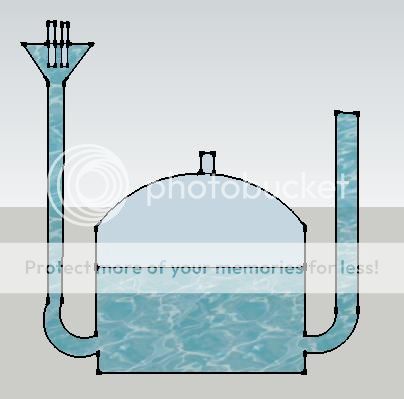

Joel Francis wrote:Here is a video of a guy using a trompe for cleaning mine waste water by increasing the dissolved oxygen.

I think an over-looked application is actually refrigeration, preservation of food, and energy storage. Air conditioning is a good secondary use after first being used for refrigeration. Also air conditioning (cooling) can be done with cooling tubes buried underground in conjunction with solar towers, but it's hard to find an alternative for active refrigeration (freezing) to preserve food year-round. Root cellars work, but not in Louisiana where I am. Bill Mollison said in the video that a property of compressed air as an energy storage medium is that the energy doesn't degrade over time and can be distributed without losing power unlike electricity. I can imagine large banks of low-pressure air tanks for storage and networks of piping throughout a community for distribution.

1

1

1

1

permaculture wiki: www.permies.com/permaculture

Those are great ideas and I will post my results. For those of you that are way smarter than me I need to be able to take whatever air comes out of there and then do a secondary compression but I can't seem to find any resources on manual compression in DIY context. Get gaskets etc to hold that much pressure may not be available on a smalls scale.

Those are great ideas and I will post my results. For those of you that are way smarter than me I need to be able to take whatever air comes out of there and then do a secondary compression but I can't seem to find any resources on manual compression in DIY context. Get gaskets etc to hold that much pressure may not be available on a smalls scale.

permaculture wiki: www.permies.com/permaculture

permaculture wiki: www.permies.com/permaculture

Thanks Katherine, I'll keep at it.

Thanks Katherine, I'll keep at it.permaculture wiki: www.permies.com/permaculture

permaculture wiki: www.permies.com/permaculture

Joel Francis wrote:Here is a video of a guy using a trompe for cleaning mine waste water by increasing the dissolved oxygen.

I think an over-looked application is actually refrigeration, preservation of food, and energy storage. Air conditioning is a good secondary use after first being used for refrigeration. Also air conditioning (cooling) can be done with cooling tubes buried underground in conjunction with solar towers, but it's hard to find an alternative for active refrigeration (freezing) to preserve food year-round. Root cellars work, but not in Louisiana where I am. Bill Mollison said in the video that a property of compressed air as an energy storage medium is that the energy doesn't degrade over time and can be distributed without losing power unlike electricity. I can imagine large banks of low-pressure air tanks for storage and networks of piping throughout a community for distribution.

2

2

1

1

Tom Robertson wrote:There was a mine that used this to create compressed air for work in the mine.

The water was pumped down a 8 inch pipe that went to the bottom of the mine.

The pipe had numerous small pipes inserted at a 60 degree angle

This allowed air into the water.

A heavy concrete tank at the bottom allowed air out.

The pressure of the air equaled the water pressure.

Water is .404 psi.

So 40 psi at 100 ft

80 psi at 200

1000 ft is 400 psi.

I believe I read about this in whole earth review

Tom Robertson wrote:With electricity, it becomes an inefficient tech.

But I can see it for back to the land movement

Any micro hydro instalation can be modified slightly to produce air pressure.

Just add air intraining

Put a tank next to the generator......

Tom Robertson wrote:Micro to me is small installations

100 ft head from 4 inch pipe.

Imagine adding air entraing.

The plastic could not handle it but a concrete 'tank' could.

I think a heavy duty tank would let the air escape the water but the water should still have its energy

I no longer have access to the family farm so I can't experiment any more with free flowing water.

I'm all for old tech finding new uses.

A epa engineer is using the air to oxidize heavy metals.

Ty Morrison wrote:Brian Whites design is interesting and relevant to this discussion thread. In fact I am still surprised.

I am really surprised at the dearth of info on pumps on Permies. Aside from getting water with your property, how to move it seems to be the next big thing that we deal with in design. Not everyone will be so fortunate as to have a site on a slope from top to bottom with enough 'head' to make a RAM pump work. So what's left? Grid driven electric? Fuel driven electric? Solar driven electric? Hand power? Gravity?

What I have discovered is that a RAM pump is pretty cool, but takes at least 18 inches of head pressure to run, And then, very slowly. This means that a storage tank or basin will be required in addition to 'head' Or you will need to use a water wheel of some sort. In Boise there is a lifting wheel design on display that was used years ago before electricity. Nothing else?

Windmills, manual or electric? This means storage too.

Screws, Siphon, Sprials...the Rife River Pump (no successful copies by DIY yet. No testimony by Permies on these either! Still storage issue.

I guess this is one of those places where electricity driven pumps is the most AT?

Thoughts?

| I agree. Here's the link: http://stoves2.com |