Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

1

1

regards, Peter

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

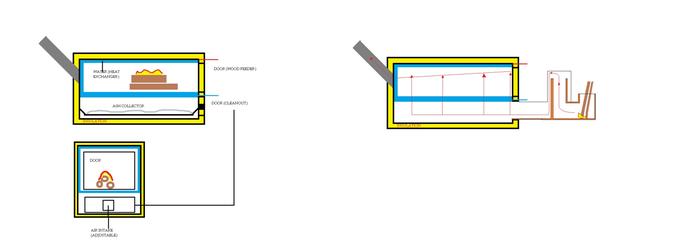

Peter Berg wrote:A suggestion: you are not interested in a mass heater, so your rocket stove should have no mass or at least as possible. Try this: the rocket and barrel in one room, and another barrel in the other. The exit of the first barrel at floor level, the inlet and outlet of the other at floor level as well. As long as those two openings in the second barrel are located at opposite sides, not beside each other this barrel will become hot as well, not a shadow of a doubt about that. This is called the bell effect, a concept some people here on this forum find difficult to grasp (or so it seems).

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

Xisca Nicolas wrote:Does the second barrel need to be insulated the same inside?

Xisca Nicolas wrote:Also, hasn't the naked pipe the advantage of releasing heat farther on?

regards, Peter

whereas a pipe would spread heat more evenly into the room.

whereas a pipe would spread heat more evenly into the room.

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

regards, Peter

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

regards, Peter

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

Peter Berg wrote:It's perfectly possible to build a stove in the floor, it has been done before. But... you are (again) unclear about where the barrel-like construction is located relative to the feed tube.

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

allen lumley wrote: You talk about putting ''tuff'' under the rocket for insulation. ... tell me what is the right word ! Don't you have pumice rock ?

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

allen lumley wrote: Xisca N.: I finally understand that it is important to you to build your Rocket Stove with as few pieces of material that would need to be imported, You want to build something That your neighbors can copy and use ! That is a Great Idea and you should keep trying to make that happen, I will help all I can !

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

allen lumley wrote: When I sent you a post about building A Rocket Stove outside, I wanted you to create your Rocket stove outside FIRST, and test It there and prove to yourself that Your Model of A Rocket Stove is going to work, this includes the use of a barrel, and as much Pipe with all the elbows in place as you will use when you bring the Rocket Stove inside!

After you can get it to work outside is soon enough to think about moving it inside !

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

allen lumley wrote:.... the Western side of one of the Islands ... a large Tsunami capable of endangering the East cost of North America !

... certain types of the Islands Rock were so porous ... Is it possible to get some of this kind of light-weight volcanic rock ?

allen lumley wrote:Yes, you could use any organic ash, Ashes from any commercial heating plants operation, using ether coal or coke

... still have a sulpher-y rotten egg smell, not what you might want in a home !

I would go with any type of perlite over vermiculite, you might find that a local greenhouse operator can get you a better price than you can get any place else on your Island!

allen lumley wrote:I can only recommend that you try to find a light weight stove pipe, as a round pipe should better flow the hot exhaust gases and transfer the heat energy to the Thermal Bench, better than a square ductwork made out of the smoothest stone and sealed with lots of care to keep the internal walls nice and smooth!

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

allen lumley wrote: Xisca : On May 6th, in an answer to Peter Burg you talk about '' the book ", can I assume that you have a Copy of Jackson and Evans' Great book 'Rocket Mass Heaters' ?

allen lumley wrote: CROSS SECTIONAL AREA '' This must be kept wholly constant through out the entire Rocket Stove Build"

every time, every place as you move from Square, to Rectangular, and to Round !

allen lumley wrote:what are your plans NOW for This '' very big plastic pipe '' (?), you have to understand that this type of pipe is insulating, and it will melt if used inside the bench too close to the Rocket Stove ! Also attempting to use this piece of pipe makes it the single controller of what size the rest of your stove gets built to, even if that means Your Stove will be too large or too small for your Actual wants and needs ! What is its internal diameter, and how long, and does it have 'specially - shaped ends'

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

, Good luck with removing the pipe after you use it for a form !

, Good luck with removing the pipe after you use it for a form !

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

allen lumley wrote:Xisca: Great ! as long as you understand that you have to honor the CSA and keep it Wholly

, Good luck with removing the pipe after you use it for a form !

A good example of a brick tower under construction

in Chris and Jenn Reinhart’s house.

A fortress of brick is mortared in to support the barrel.

Xisca - pics! Dry subtropical Mediterranean - My project

However loud I tell it, this is never a truth, only my experience...

So what I was talking about was probably on the bottom of your 43 ! Most everyone who still builds a Heat Riser /

So what I was talking about was probably on the bottom of your 43 ! Most everyone who still builds a Heat Riser /

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

| I agree. Here's the link: http://stoves2.com |