Wonderful questions!

And that video does want a little follow-up, since it's been several years.

Thanks for being willing to take the answers in a public forum.

Mort Smith wrote:So I sent Erica an email and she requested I post them here to make the discussion more available to people - so here goes!

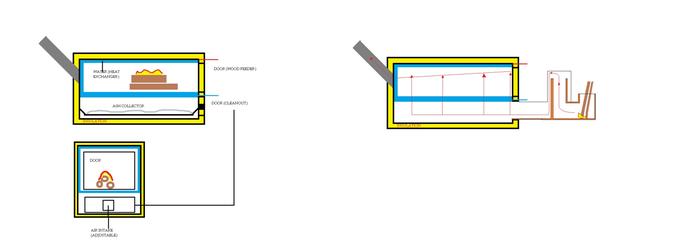

So I saw a video on youtube (https://www.youtube.com/watch?v=6lUCOowOmJ8) where you were installing and demonstrating using a rocket heater as an underfloor heating system and the switch between the short path exhaust and the long path to heat the subflooring area. I thought it was brilliant.

So -

1. - How did that turn out? Was it as successful as you expected? Did the heating dry out the wood floors? Would another floor surface work better?

The first thing I have to admit is that the particular heater in question was an experiment in an abandoned sheep-shed. There were grand plans for some co-owners to refurbish it and live there... but it turns out refurbishing an abandoned sheep-shed is a substantial amount of work, and making it livable even more so.

Some things that were not as successful as we hoped included

- the chimney (a bit short, any chimney under the eaves tends to get puffs of backdraft from passing winds).

- the insulation (a lot of the volunteer help, over time, seemed to have no idea that it should remain in place, and we weren't out there directly supervising)

- the follow-through.

Some things that worked well, given their limited testing:

- the bypass to prime the chimney did work, which is a nice thing given how we had to improvise the flapper for it.

- the mix of cob/dirt over the pipes did hold a fair amount of heat, once warmed up

- allowing for the crappiness of the chimney, the performance from that relatively long loop of pipe seemed OK. I would consider using the same layout, with a more vertical/indoor chimney, for a future project.

Mort Smith wrote:

2. How much floor space would a system built that way heat? I'm looking to build an oregon cob home (in Oregon or Washington, land prices/availability at the time kind of deciding where I purchase this year) with an internal floor space of approximately 20'x25'. Ish. Subject to some minor revision - but the end result will still be in that ballpark for total sqft or smaller. It's a lot of cob to make after all. EDIT: In fact, it's hella a lot of cob to make and I'm seriously considering straw bale instead - it's already covered in the Oregon building code (permits! YAY!) and much easier and faster to do.

That sounds like about the size that our shed was - maybe 20 x 20 if I recall.

If you find land you can afford in the milder coastal climates, it would be no problem with any decent building envelope.

If you end up in the harsher winters inland, straw bale would definitely be the way to go. You could probably enhance the heat capture off the barrel by making sure that wall was about 8" of cob behind the barrel, with strawbale or another form of insulation between that and the outdoors. Personally, I'd put the barrel up against a non-combustible interior wall and heat two spaces (but don't plaster the barrel into the wall! It is a bear for later maintenance.)

Mort Smith wrote:

3. Would that be too much space for one underfloor "long path" to handle? I understand that there is a limit to how far the exhaust can be pushed/pulled through the system and don't want to overload it - math is not my strong point, but I definitely get it enough to know there are limits.

Seems like part of the question above...

Building Heating loads are not really about square feet of space - they're much more about how fast the building loses heat to its surroundings.

Major factors are:

wall surface area (and window/door areas)

wall R value (insulation) (and window/door R values)

ceiling and roof exposed surface and R value (affected more greatly by both infiltration and radiant heat loss)

floor - mostly depends on whether perimeter is well-insulated, but sometimes you figure crawl spaces and basements and slab-on-grade differently.

seals or gappiness of construction

how cold the climate is, compared with how warm you want the building to be - average is called HDD or Heating Degree Days

how hot the climate is, when you want to cool the building (called CDD or Cooling Degree Days)

You can also calculate out various advantages - like passive solar heat gain from well-placed windows, vs. added insulation from drapes...

and you can game the system. a round wall has a lot less exposed surface than flat walls, let alone those weird little pseudo-additions and gables they put on lots of homes these days.

There are other factors that are not taken into account when calculating heating loads by modern engineers: to my mind, they all add up to:

- how easily you can stay warm without heating the building up as much.

A contact surface (radiant floor or heated seating) allows you to keep the room air much cooler.

Radiant heat allows you to conserve heat in people and things, and sacrifice less heat to the air (and the necessary ventilation for health).

Air movement tends to cause evaporation, and has a chilling effect- so if you're heating with hot air, the "comfort" temperature is going to require hotter air than with other methods.

Mort Smith wrote:

Here's my thought if it was - since you created that whole nifty switch thingy - what if there were two separate "long path" duct systems built under the floor - could you heat one, then the other using the switching system? Say I want the kitchen and main living area toasty toes primarily during the day, but then I want my sleeping area on the other end warmed up before bedtime. Or if it's really butt ass cold outside - do one and then the other right after, alternating the firings as needed.

Is this a viable idea? Because I really want it. Since cob requires a solid foundation anyway, putting in a subfloor shouldn't be an issue. I was thinking about a tiled floor, but I am totally open to suggestions that would enhance the heating properties.

Thanks!

Mort Smith

I would definitely do the tile floor rather than a wood floor, if you have the option. Integrating combustible (and rot-prone) wood alongside masonry is just kind of a hassle. They move differently, so tend to crack and wear on each other, and they are not easy neighbors in contact. Detailing it well, so you can get them in close contact, takes experience and patience; you can always go back and re-plaster, or carve out expansion joints, where you don't get it right the first time though. Just try to stabilize any expansion cracking at its widest, so there's room for it to expand that wide again.

Two switched paths should be do-able. Two design considerations:

1) Can you design the switch(es) in such a way that there is always 100% flow to the outdoors? The more handles and knobs you put on something with a fire in it, the more likely that you will end up trying to solve damper-logic puzzles in a room rapidly filling with smoke. Unfortunately, most people get more stupid when a) panicking and b) oxygen-deprived, so this sort of logic-puzzle strikes me as kind of a cruel joke that mostly happens to "smart" people (people who are more intelligent than they are wise).

When I do a bypass, I always do it so that either open or shut, the fire still has an escape route without backflow. I have used swivel-flapper valves on most of the bypasses we've done, but a two-loop path might require something else like a slider or something. This limits my design options, but given that a lot of my experiments are left for someone else to deal with, it gives me a great deal of peace of mind.

Two other bypasses we've done have worked well for their owners.

One replaced the original bypass with a bunch of more robust controls that do require a modicum of 'smart' to operate, but they allow him to really test out the different responses of the system. To my mind that's fine in a lab (or in an office/lab, in his case) but I would not do it in a sleeping space... I try not to take more than 1 or 2 steps toward danger with any given experiment.

2) Thermal mass vs. radiant heat: Roughly half the heat of the stove is put out via the barrel. Cobbing the barrel makes the system not work as well (you didn't ask, but others will and have).

So if you are switching back and forth to slowly charge up two thermal masses, each of which has a long response time, the room with the barrel in it is going to get very hot meanwhile.

I tend to like to manage these sort of time-and-use questions passively if possible:

Can I put the bedroom above the evening-heat area, so that I can open a stairwell door or loft door to take advantage of that naturally rising heat at bedtime?

Can I manipulate the thickness of masonry on each side of the heated pipes, such that the maximum heat reaches one side later than the other?

The biggest question is usually, Where can I put that radiant barrel so that it is in line-of-sight with as many rooms as possible?

Because if it's in a tiny room at one end of the house, and there is a tiny room three walls away at the other end, you are never going to warm up the far room (duct path or not) before the barrel room is way to hot for sane comfort. Most people don't want a barrel smack-dab in the middle of the room, however. And my new second-favorite thing to do is get a massive vertical slab (like an interior wall or half-wall) on one side of the barrel, to soak up all that radiant heat and share it with an adjacent, but perhaps more private, room.

Having the barrel in line of sight usually puts the fuel feed in sight too, which means you can conveniently operate the heater from several rooms, while doing all manner of other things.

If you are looking at running one barrel-unit to heat two mass-units, you will be running the barrel a long time, so you might have something like adjustable heat-shield wings or doors around the barrel to reflect that excess heat to the various spaces too.

Hope that helps!

I do think an under-floor design is a good experiment, and I would continue working with this design.

We did a fairly standard rocket mass heater buried in a new sub-floor to be covered with concrete slab up in the Olympic peninisula a while back, and I have not heard from them so I imagine all is well. (The organizer was a conscientious guy and I believe he would have let me know immediately if there were problems.. but I should check in to see how it's going.)

Other under-floor rocket mass heaters I've seen or heard about have often involved radiating manifolds with lots of smaller pipes, embedded in a cob floor. I know of one 12" heater with something like 11 4" pipes coming off it (however it worked out, the smaller pipes combined had a bit more cross-sectional area than the heater's firebox and manifold). Another was I believe an 8" heater with about 7 5" pipes. I think you could do an 8" system with 4 5" pipes, if that was convenient, manifolding them out near the barrel and then re-joining them to a single 8" chimney. You want the manifolds to be big, accessible boxes where you can pop a lid and fiddle around inside.

If one area is too hot or too cold, you can restrict flow to certain areas just by sliding a stone or brick across that pipe's entrance.

Then there is the 'plenum' idea, where the whole floor is tile supported on masonry pillars over a cavity. These are used with big honking fireboxes for the k'ang, ondol, and hypocaust systems. But there is a constant concern and various techniques for making sure the hot exhaust doesn't creep through floor cracks into the room. Some use layers of tile, clay, and tarpaper or oilcloth with more clay over that. Then you have to tear out the floor periodically to clean the plenum...

I think the 'zone heating' idea has a lot of promise, though. Much easier to keep the flows consistent with same-sized pipes, and a standard set of options where you can easily track the results of different settings over time.

I wonder if it would be worth making it so you could do 4 different paths:

- zone 1 only

- zone 2 only

- longest path: zone 1 first followed by zone 2

- longest path: zone 2 first followed by zone 1

Whichever path is shortest could double as a priming route, or there could be an option 5: bypass from combustion to exit-chimney through the junction of all zones.

If you pull too much heat off the exhaust, it can get foggy and sluggish. (Come to think of it, I do too.)

So in a system with 2 loops, I'd adjust our rules of thumb like this:

Usually with an 8" system, I could do a 50' linear path, or a 40' path with 2 90-degree bends (down and back), or a 30' path with four 90 degree bends (like an L-shaped bench with two 90's and a 180 at the end).

We subtract about 10 feet for each 180 degree turn, or 5' for each 90-degree turn. This is all with smooth, not corrugated, metal duct or stovepipe liners.

I would want the total longest possible path, not just the longest loop but including any paths from the combustion area to the junction, and junction to exit chimney, to fit within the above rules. Those are the maximum workable length. The under-floor system in the video was one of the test cases for that max - it's about 40 feet linear, and has 2 45's, 2 90's, so it's about 5 feet over its hypothetical max length.

So the longest the 'longest loop' could likely be would be about 30 feet, assuming it returns where it started, and the heater is maybe 1/3 of the way from a wall (more centered) instead of being completely on an exterior wall.

I would want to allow maybe 5 or 10 feet to spare, assuming the junction system will not be perfect, and may create some unexpected drag on the system.

I would be tempted to make each 'zone' not more than 20 feet long, with a 180 total turn angles, so that I could play with running both loops or just one.

But if you need one long and one short loop for some reason, that could work too.

I would be tempted to do a vertical chimney, near the barrel, so that part of the barrel's excess heat will boost chimney draft and pull heat through the loops faster. There could be other thing that would make sense, but this is my starting point so I don't need to concern myself with priming. Also I like how the chimney tells people "hey look, it's a stove!" hopefully before their 3-year-old runs up the bench and melts his shoes on the barrel. (Your 3-year-old running up my couch to jump on my barrel has other problems, too.)

I have just realized it is 5 am. So technically, this is not "free advice in my free time" - it's "free advice of dubious quality while sleep deprived, during time that should be rightly reserved for sleep."

I hope it is somewhat useful anyway, and I am going to post it in case actual "free time" does not occur in the near future.

Yours,

Erica W

1

1

1

1

1

1