3

3

1

1

2

2

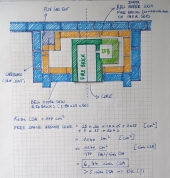

Erik Slagter wrote:We are not sure if we need to partition the air path going to the bench. Otherwise the air might just directly go outside, through the pipe, right? We want the cooler air, that has been through the bench, to go outside the pipe.

Erik Slagter wrote:We've not glued the firebricks, they are just dry fitted. I was thinking of using "Quick Fire" Masilla refractario , or do need to use actual refractory mortar? Or just clay /sand mix? Is this 'refractory paste' ?

regards, Peter

Peter van den Berg wrote:

The trick was that the exit opening was wide and low, lower than halfway up the bench' height. That's it, nothing more to it.

I guess you have experience and you get it

I guess you have experience and you get it

Peter van den Berg wrote:

In order to work well, the opening between bell and bench need to be full width and height, exactly as the inside of the bench. No ridge or lintel at all that's lower than the bench' ceiling.

Of course you are free to do what you see fit, build a separation wall inside or whatever. The only sure thing is that in that case the heat extraction part is posing friction in the smoke path which will in some way hamper this in my opinion already cramped heater

Peter van den Berg wrote:

I am unable to recommend any of the refractory mortar you are able to buy there. Have a look at the text on the bag or bucket, when it says aluminium cement it's quick drying mortar. So quick, that it dries on the brick as soon as you apply it. My advise: buy the smallest amount of all the brands available and try all of those.

1

1

Erik Slagter wrote:For us, we could not understand how it works looking at the Mallorca build. It's magic to me

I guess you have experience and you get it

Erik Slagter wrote:We are going to remove the partition for the exit pipe. But we need some way to support the bricks on top, is it ok to have the bricks in the middle in order to achieve that or will it that pose friction?

Erik Slagter wrote:We are going to see what we can get. Not sure: do you recommend the aluminium cement or not? We notice that even clay&sand dries almost instantly with the firebricks. Could we use clay&sand instead of refractory mortar?

regards, Peter

1

1

Scott Weinberg wrote:I do not mean to add a twist to this discussion, but much of the talk is about the bonding and setting of the fire bricks, thus my question

Can the Cordierite type of shelves be used in various areas requiring spans beyond the length of fire brick (almost always the tops of each design) with fire brick placed over top? These are often advertised as Kiln shelves and such.

Perhaps if any cutting is done to these shelves, they are no longer strong? Just wondering.

Fox James wrote:You dont have a huge choice when it comes to bonding the bricks together, fire clay mixed with two parts sand is a very popular method but can be very messy and does not add a strong structural bond however it will seal the bricks together and is easy to take apart should you wish to rebuild.

As I say this is what most people seem to use on mass heaters.

Fox James wrote:

Refractory cement (Fondue cement) mixed with four parts fine sand will offer a strong bond if used correctly but, requires soaking the bricks beforehand and can only be mixed in small batches because it sets very fast.

Fondue cement mix is not easy to use unless you have experience with brick laying and understand it cant be manipulated like a Portland cement mix can be!

Fox James wrote:

Home brew is a good alternative and can be used in medium heat areas up to 400c

This is a mix of fireclay, lime, portland cement and silica sand the ratio is 3 sand 1 cement 1 lime 1 fireclay powder.

Home brew is very user friendly and easy to clean up, making a neat job.

Home brew is the choice of brick oven (pizza ovens) builders so it is very proven.

In all cases the bricks need to be wetted with water just before being used and with the Fondue cement, soaked for 5-10 minutes.

A lot depends on your ability, confidence and especially …. how you want the finish to look.

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

2

2

Silence is Golden

For all your RMH needs:

dragontechrmh.com

regards, Peter

1

1

Fox James wrote:Eric, I wonder if you can fill the holes by in pouring in self levelling cement, this a product I use a lot and is a very low viscosity product that might just find its way down.

You should be able to find it very easily, you can mix it in a jug and pour it down, it goes hard in 20 minutes.

Whatever you decide, you most definitely need a hight mass material for the top!

PS i do feel for you as you are obviously trying hard to get it right …..

4

4

1

1

Fox James wrote:That is a difficult question without knowing what the temperatures will be….. any porous stone that carries moisture is likely to crack if the temperatures goes over boiling point, the moisture will turn to steam and expand at an alarming rate causing some stone to literally explode. (Granite is a good example)

If the stone is completely moisture free but has air pockets the same thing can happen.

So material like fire brick is very uniform and dense with no air pockets however, even fire brick can crack if exposed to rapid heating and the brick is wet!

For the same reasons made made materials like refractory cement or pizza stones, need to be cast carefully and vibrated to remove all chance of trapped air.

Adding steel is a common mistake as the metal will expend at a different rates to the surrounding material and almost always cause cracks.

However, a properly cast refractory slab will be a very safe bet, up to date methods use burn out fibres that melt at low temperature and allow moisture to escape and also use high temp fibres like carbon, that add strength.

Unfortunately this type on refractory is not easy to DIY.

In you case, living in Spain, I would look to pizza oven supplies as there should be able to at least recommend something suitable, if not supply you.

3

3

2

2

3

3

4

4

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

4

4

Erik Slagter wrote:I thought a 5cm spacing between the riser and the ceiling of the bell was the ideal, but we're not sure anymore. My wife thinks about 20cm (2 layers of bricks on the side). Can someone refresh us? I can't find the source anymore.

regards, Peter

1

1

4

4

1

1

4

4

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

1

1

1

1

|

He baked a muffin that stole my car! And this tiny ad:

Our PIE page has been updated, anybody wanna test?

https://permies.com/t/369340/PIE-page-updated-wanna-test

|