Dustin & Ping, Galt's Retreat. Voluntaryist Ecovillage

http://www.ic.org/advert/voluntaryist/

https://www.facebook.com/groups/286170261745393/

Dustin Krieger wrote:do I just pull it all back up until I am dealing with just ceiling joists and no endboards on them and then bring in the rafters ?

My opinions are barely worth the paper they are written on here, but hopefully they can spark some new ideas, or at least a different train of thought

Dustin & Ping, Galt's Retreat. Voluntaryist Ecovillage

http://www.ic.org/advert/voluntaryist/

https://www.facebook.com/groups/286170261745393/

Dustin & Ping, Galt's Retreat. Voluntaryist Ecovillage

http://www.ic.org/advert/voluntaryist/

https://www.facebook.com/groups/286170261745393/

2

2

Creating sustainable life, beauty & food (with lots of kids and fun)

Dustin Krieger wrote:Tried to post pictures but it won't load them from my phobe

Dustin & Ping, Galt's Retreat. Voluntaryist Ecovillage

http://www.ic.org/advert/voluntaryist/

https://www.facebook.com/groups/286170261745393/

Dustin Krieger wrote:I'm near a huge Amish community in tn lawrenceburg, I'll ask around. I plan to rebuild my roof correctly with a peaked roof style the cabin is roughly 8 x 16 any suggestions on how to correctly build a parts list for this diy and any suggestions on what angle to use? I wouldn't mind a little storage space in the attic area but I'm on cinderblocks on a hilltop in a forest maybe wind could be bad I'm not sure. I try to always ask advice on diy projects. P.s. If there is a way to get it done without having to move out of cabin it would go over better with the wife. Thanks guys,

I could upload pics if it would let me the phone says this app doesn't have permission and I haven't figured it out I'll try more

Dustin & Ping, Galt's Retreat. Voluntaryist Ecovillage

http://www.ic.org/advert/voluntaryist/

https://www.facebook.com/groups/286170261745393/

Creating sustainable life, beauty & food (with lots of kids and fun)

"...specialization is for insects." - Lazarus Long

Universal Introduction to Permies

How Permies.com works

Dustin & Ping, Galt's Retreat. Voluntaryist Ecovillage

http://www.ic.org/advert/voluntaryist/

https://www.facebook.com/groups/286170261745393/

2

2

Dustin Krieger wrote:How can I jack that building up affordably? Mind you I have to haul lumber or anything 300 feet uphill from the street so some heavy things might be out

Can I make a ridge board from multiple 2 by 8 s here ? And can anyone help me build a material list? I have to get this delivered

"...specialization is for insects." - Lazarus Long

Universal Introduction to Permies

How Permies.com works

1

1

Dustin Krieger wrote:How can I jack that building up affordably? Mind you I have to haul lumber or anything 300 feet uphill from the street so some heavy things might be out

My opinions are barely worth the paper they are written on here, but hopefully they can spark some new ideas, or at least a different train of thought

Dustin & Ping, Galt's Retreat. Voluntaryist Ecovillage

http://www.ic.org/advert/voluntaryist/

https://www.facebook.com/groups/286170261745393/

2

2

Dustin Krieger wrote: and stick rebar down into that pointing up (through the bottom sill plate?) would that be sufficient? would 2 corners (the downhill corners) be enough to maintain stability?

Never used concrete in my life, so all this is new to me. I wanna make sure I fully understand this before moving ahead.

My opinions are barely worth the paper they are written on here, but hopefully they can spark some new ideas, or at least a different train of thought

Dustin & Ping, Galt's Retreat. Voluntaryist Ecovillage

http://www.ic.org/advert/voluntaryist/

https://www.facebook.com/groups/286170261745393/

Dustin Krieger wrote:made first post (had to eyeball it for final height) sunk it 17-18 inches in ground and have 2 1ft rebar inside it near the top.

Back are on blocks as well, 1 on the 'right side (facing door from outside) and 2 on the left side due to slope. My goal was to post the left side front and back (the downhill side) and hope to sit it back down on those to keep it from ever sliding. Its not on the dirt, but only a few inches off it on the uphill side.

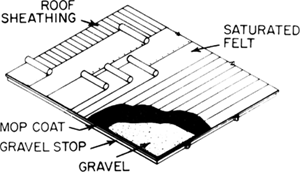

My next goal would be to get my solar setup and build a real roof, and add some siding. I was thinking of windlocked asphalt shingles (i read about em, no idea what they are yet, sound good)

My opinions are barely worth the paper they are written on here, but hopefully they can spark some new ideas, or at least a different train of thought

Dustin & Ping, Galt's Retreat. Voluntaryist Ecovillage

http://www.ic.org/advert/voluntaryist/

https://www.facebook.com/groups/286170261745393/

My opinions are barely worth the paper they are written on here, but hopefully they can spark some new ideas, or at least a different train of thought

Dustin & Ping, Galt's Retreat. Voluntaryist Ecovillage

http://www.ic.org/advert/voluntaryist/

https://www.facebook.com/groups/286170261745393/

My opinions are barely worth the paper they are written on here, but hopefully they can spark some new ideas, or at least a different train of thought

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

No rain, no rainbow.

Dustin & Ping, Galt's Retreat. Voluntaryist Ecovillage

http://www.ic.org/advert/voluntaryist/

https://www.facebook.com/groups/286170261745393/

Dustin & Ping, Galt's Retreat. Voluntaryist Ecovillage

http://www.ic.org/advert/voluntaryist/

https://www.facebook.com/groups/286170261745393/

Dustin Krieger wrote:Tile roof? Unfamiliar

No rain, no rainbow.

Dustin Krieger wrote:Trying to put a better roof than my friend did

1

1

Dustin & Ping, Galt's Retreat. Voluntaryist Ecovillage

http://www.ic.org/advert/voluntaryist/

https://www.facebook.com/groups/286170261745393/

No rain, no rainbow.

Dustin Krieger wrote:I could take that floor ceiling off, it's only caulked a bit to bugproof. I don't know that I could get trusses carried up there though!

My opinions are barely worth the paper they are written on here, but hopefully they can spark some new ideas, or at least a different train of thought

Glenn Herbert wrote:Clay tile is a beautiful material, but unless you have a ready supply of fine clay with few stones or other impurities (like Georgia clay beds), it will take a huge amount of processing before you can make tiles, and firing them hard enough to stand frost in damp climates is a much more intense process than the lovely kiln in the video.

No rain, no rainbow.

|

No one can make you feel inferior without your consent - Eleanor Roosevelt. tiny ad:

The new kickstarter is now live!

https://www.kickstarter.com/projects/paulwheaton/garden-cards

|