Apologies if this posted twice.

Ted:

Unfortunately there is quite a bit of misdirection in the replies below and not wanting to offend anyone I will try to give you some guidance in principle and for your application. Please everyone, tolerate my alternative interpretations as just that.

>I remember somebody saying that if you close up a chimney with a baffle that is just a metal plate that closes over it, that it would be friction and slow down the fire.

This is correct, such a device is called a chimney damper for the reason that you "dampen the fire" in the sense of slowing down the burn rate. A damper is quite permissible provided that it is not able to close off the chimney completely. There are often regulations about this where the area can be reduced by 2/3 leaving 1/3 open when fully closed. This is essential for late fire emissions to escape. Most stoves (including rocket mass heaters) have poor combustion in the late fire due to high excess air (far too much air for the fire's requirement) and poor control over it.

Mostly, it is not a good way to control a fire's burn rate. In all cases possible, the system should be constructed so as to limit the ingress of air, not the egress of gases. When the entrance is limited, and the chimney is pulling, any leaks permit air to enter the stove, whereas in the opposite case the gases inside try to leak out. A negative draft maintained on the top of a fire should be about 20 pascals if you can arrange it. That is very little, but it means a warm chimney pulling and air entering the stove through the controller with the entrance as the restriction on the system.

CO leaking out of the stove into the room is not heavier than air. CO2 (44 mole mass) is and sinks, but not CO. CO is almost exactly the same density as air (28 mole mass) and disperses very effectively throughout the room causing problems. The mechanism is it displaces oxygen on the red blood cells so it lowers the oxygen carrying capacity of the blood.

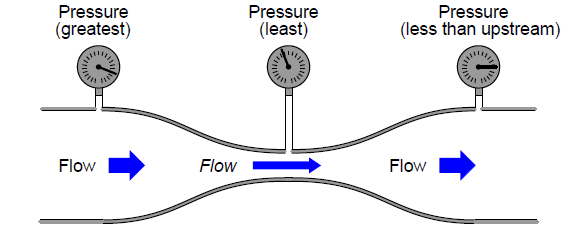

>Does a hose nozzle work as a venturi or a restriction?

Anything that reduces the flow up a chimney will reduce the exhaust gas flow rate. The temperature of the chimney above and below the restriction will change if you change the amount of that restriction. This will affect the total draft on the stove. Generally speaking, all stoves in the USA have exhausts that are too large in diameter to work properly, the chimneys are too large in cross-section, and the exit temperature is too low to be effective. That is a pretty broad condemnation, but it is just how it is. Most stoves require a barometric draft regulator but do no get it. If the chimney is hot enough to work properly it tends to generate thermal runaway: more heat leads to more firepower leads to more heat in the chimney leads to more firepower. That is not how most people want their devices to operate.

Draft in a chimney is a source of "power". You could use a fan, but a warm chimney is capable of "doing work". So a chimney is really a natural fan. The power available can be directed in various ways: You could turn the energy into a "suction" on the fire and the air entrance (the preferred option). You could dissipate the energy creating a high velocity flow gases past the restrictive plate you are considering, slowing down the total flow. Given any constant temperature in the chimney, the available energy could pull a lot more air quickly, or more slowly but having a high flow rate past the restriction point. You may have a reason for wanting that. You could use a small diameter chimney so the energy was dissipated along the whole pipe length limiting the flow to a certain desirable rate. Usually that is a good idea. The main point is there is energy available and you can choose were it is applied. It might be at the secondary air entrance adding velocity (one of my favourite design ideas.)

Now for your main motivation:

>...also at the same time be a restriction that would allow soot to burn up completely (actually in a restriction that speeds it up, soot particles should shrink just on that).

What you describe is a fire that is not burning cleanly, followed by some attempt to fiddle with the flow rate of the gases in order to reduce the smoke generated. It is already too late. If the fire is not burning cleanly in the first place, it is far better to burn better than to try to clean up what should not be there. Slowing down the gas flow rate in the chimney is very unlikely to correct a bad combustor design. That is not how things work. Poor combustion has several classic causes so addressing them is a better approach.

>...but really burn up those soot particles and shrinking them too

Smoke particles don't "shrink". They grow, rapidly. You are quite correct that they are combustible. Smoke is almost entirely made up of unburned fuel and water vapour. A small amount of a typical stove's emissions is ash, not the products of incomplete combustion. Creating good operating conditions for combusting biomass requires meeting certain conditions.

One is an oxygen level of about 8% to 10% in the exhaust. This is air which is not required to burn the fire. Biomass is not as easy to burn as gaseous fuels which can tolerate very low excess air levels (even 1% or less O2). If you have 18% O2 in the exhaust, that is 600% excess air and it FAR too much to burn cleanly.

The calculation is: Measured Oxygen %/(21% minus measured Oxygen %) The answer is the excess air factor, so multiple by 100 to get %.

Note that it is not the total air demand, which is Excess air + 100% also called "Lambda".

All that unwanted excess air cools the combustion. Slowing down the exhaust does not guarantee the O2 level will drop. It might, it might not. It depends on the architecture of the stove. But one thing for sure, it should not be more than 10% when running on high power. If you have a technically sophisticated burner, you can get it down to 6% but that is not for the ordinary hacker. Instrumentation is required.

You are correct that if you burn the smoke it will yield more heat. However burning the CO gives far more heat than burning the smoke. C to CO yields about 8 MJ per kg of fuel. CO to CO2 gives more than 24 MJ/kg. So if you lose a lot of energy to CO (bad combustion), you can get it back by burning the CO instead of carefully venting it outside. Emitted CO is a called a "chemical loss".

To keep CO burning needs about 820 C above the combustion zone. This is NOT provided by blowing harder on the air supply, which will just force more cold air though the chamber, cooling the fire. Blowing on a charcoal or coke fire like a blacksmith usually create a lot more heat, but huge amounts of CO. Such a fire is not a good example of clean combustion at all. Hot, yes, but not clean.

To get a clean, hot burn, your fuel load should match the grate area and a lot of other things. Most stoves have:

too large a grate

too large a fire chamber for the typical fuel load

too much primary air

too large a chimney diameter

too little insulation around the combustion zone to maintain a hot fire needed to light the CO produced

too low an operating temperature

too little draft or

Too much draft without a barometric draft regulator

Putting an air control at the air entrance is how to control the fire intensity.

Secondary air (if supplied) should be approximately twice the primary air supply and where possible, preheated. If you want to burn wet wood, the primary air has to be preheated (big emissions reduction).

Most stoves have far too much primary air so any secondary air is just a waste of energy as the air goes in, is not used or needed, and carries heat up the chimney.

Very clean burns can be obtained without any grate - see Masonry Heaters available from the Masonry Heater's Association website. If the floor of the chamber is made from firebrick, effective combustion can be maintained for a long time. Recent developments in combustion include placing a layer of small stoves (20-30mm) over the whole fuel bed (still no grate). This may not suit people burning 24/7 however, try it and see the difference. It reduces smoke generation a lot in some cases.

Very high performance stoves (called HELE for high efficiency low emissions) have a surprisingly low chimney gas velocity of 150 to 250mm per second in a chimney that is about 1 square inch (6.5 cm^2) per kW of firepower. When you compare that with what is usually provided or "required" you may be surprised.

General rules are: burn first, clean and hot. Then transfer heat to some surface, then vent what is needed to operate the chimney properly. Do not use a chimney as a heat exchanger save for the first few feet. Once heat enters the chimney, keep it there to operate the draft into the stove properly. You gain nothing from a warm chimney after it departs the heated envelope, i.e. above the ceiling.

Good luck with your investigations. Modern HELE stoves can be see (drawings and all) in the Library of www.newdawnengineering.com under Library / Stoves, then by country. One you might check out is the KG2.5 under Kyrgyzstan. Have a look at the function of the "flame tube" which burns smoke and CO as it enters the heat exchanger. It is so effective that the top of the heat exchanger serves as a third cooking position. The Kyrgyzstan project is quite interesting. You can read about the development of the main stoves here:

https://openknowledge.worldbank.org/handle/10986/31282

(click the download button)

A precis is available at

https://openknowledge.worldbank.org/bitstream/handle/10986/31774/Beyond-the-Last-Mile-Piloting-High-Efficiency-Low-Emissions-Heating-Technologies-in-Central-Asia.pdf

And the dramatic impact it produced on people here:

https://www.nature.com/articles/s41533-019-0144-8.epdf

Stay well.

Crispin

4

4

8

8

3

3

2

2

2

2

2

2

2

2