2

2

positively optimistic 🙂 https://www.youtube.com/@613Builds

Self-Proclaimed Renaissance Man and Gizmologist.

positively optimistic 🙂 https://www.youtube.com/@613Builds

Self-Proclaimed Renaissance Man and Gizmologist.

1

1

Self-Proclaimed Renaissance Man and Gizmologist.

positively optimistic 🙂 https://www.youtube.com/@613Builds

1

1

Self-Proclaimed Renaissance Man and Gizmologist.

1

1

Self-Proclaimed Renaissance Man and Gizmologist.

1

1

Peter Chauffeur wrote:Hello Gerry,

I hope these answers satisfy your questions.

A1) The Primary cover is a repurposed glass pen holder with holes thru it that just so happen to give optimal burn and air mix that helps keep the burn chamber clear of ash (ash ends up being pushed down into the stainless steel burn pan directly under the primary burn chamber. There is no air adjustment per say, but I have found that sliding the pellet basket forward or backward in the burn chamber does allow for some heat output adjustment. Designing the pellet basket to allow for just the right size of ember to fall thru the grate down into the stainless burn pot.

Greetings from Brambly Ridge

1

1

Self-Proclaimed Renaissance Man and Gizmologist.

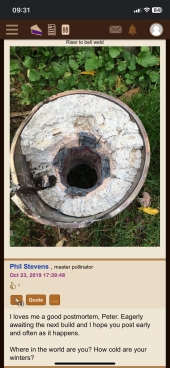

Peter Chauffeur wrote:My First Rocket Stove Fabrication!

Hello! I have completed my First Prototype Rocket Stove. It is capable of heating a 2000 square foot home and burns about 1.25 pounds of wood pellet fuel an hour. It is designed to run for hours at a time without fussing with it and requires no electricity to operate. It has unique feature that uses supersaturated steam to help with a cleaner burn and regulate the intense burn chamber temperature. The refractory acts as a mini thermal mass and stays warm for about 3 hours after the pellets burn off. The stove is started up in the morning using a propane torch and is shut down at nighttime. This stove has run for over two years now. I originally posted the build on Instructables for a metal build contest and it got 10k views in the month I had it on their site. I decided to take it down because I didn’t feel it was the appropriate site. I know that wood pellet isn’t exactly “salt of the earth “ homesteading but it is using a renewable resource. One would have to make a larger burn chamber for split wood.

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

Self-Proclaimed Renaissance Man and Gizmologist.

Self-Proclaimed Renaissance Man and Gizmologist.

1

1

Self-Proclaimed Renaissance Man and Gizmologist.

2

2

Self-Proclaimed Renaissance Man and Gizmologist.

1

1

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

1

1

Self-Proclaimed Renaissance Man and Gizmologist.

Self-Proclaimed Renaissance Man and Gizmologist.

1

1

![Filename: download.png

Description: [Thumbnail for download.png]](/t/123654/a/105720/download.png)

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

1

1

1

1

Self-Proclaimed Renaissance Man and Gizmologist.

Self-Proclaimed Renaissance Man and Gizmologist.

Self-Proclaimed Renaissance Man and Gizmologist.

Self-Proclaimed Renaissance Man and Gizmologist.

Self-Proclaimed Renaissance Man and Gizmologist.

Self-Proclaimed Renaissance Man and Gizmologist.

Self-Proclaimed Renaissance Man and Gizmologist.

Self-Proclaimed Renaissance Man and Gizmologist.

Self-Proclaimed Renaissance Man and Gizmologist.

1

1

Self-Proclaimed Renaissance Man and Gizmologist.

Self-Proclaimed Renaissance Man and Gizmologist.

Self-Proclaimed Renaissance Man and Gizmologist.

1

1

Self-Proclaimed Renaissance Man and Gizmologist.

5

5

Self-Proclaimed Renaissance Man and Gizmologist.

3

3

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

|

Never regret anything that made you smile. - Mark Twain / tiny ad

permaculture thorns, A Book About Trying to Build Permaculture Community - draft eBook

https://permies.com/wiki/123760/permaculture-thorns-Book-Build-Permaculture

|