posted 7 years ago

You will need to place the tank higher than the heat excanger at the heater, give it large enough waterways and it will flow just fine. A coil will not thermosyphon for you its a bank of traps like a drain trap uses to keep the pipe sealed.

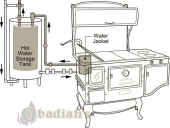

A heat exchanger that is a parallel manifolded riser set or a column will work. For single columns they need to be large, 3" is getting there. A tank with its lower third in contact with the stove will do the same. This allows a conveyor belt within the pipe (or tank) from heat source to a storage in the reverse of say, a double pane window, where the spacing of the panes (1/2 or less) stops gases from thermosyphon/convection heat loss.

At 3", liquids will have room for a circuit or conveyor belt for heat, warmed water rising and cooler water falling within one pipe. A pot of water does this on the stove!

For a heat exchanger on a wood heat plant without a pump or circulator, there would likely be several to dozens of vertical risers or pipes that have a common manifold head and foot horizontal, connecting them. A ladder on its side is a similar concept visually.

If you feed the diagonal opposed corner and place the bottom of the tank any higher than the outlet or at least theas high as the inlet, heat will drive a thermosyphon until you stop feeding the heater wood and it cools. This detail, parallel manifold, diagonal opposed inlet and outlet, causes fluid to flow evenly through all risers.

Even a small tank could be the HE, imagine a briefcase shaped tank pressed to the back of the stove or heater and two 1" pipes, (big is good but need not be) one feeding the bottom and one coming from the top and the storage tank in line and higher than the HE outlet. That machine will work too, possibly not exactly as laid out in that you may have the HE inside the heater or other details which i cant know.

I am absolutely not a physics professor, and not a fluid dynamics expert. I have though, installed quite a few thermosyphon solar heating systems for domestic hot water and space heat, air and hydronic.

My heater has a coil pressed into contact with a heat shield on the back of the outside of the stove and a circulator to run the heat to an unpressurized storage tank and dhw from an immersed coil. Great system, ivan labs circulator and an Art-Tec pv or battery powered differential thermostat.

The point of that is...... its coming out and i will arrange it as a thermosyphon system for the same reasons you have..... never going to have an overheat (produce steam pressure) caused by a failed controller or circulator, sensor, etc. !

1

1

1

1

4

4

5

5