1

1

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

“The most important decision we make is whether we believe we live in a friendly or hostile universe.”― Albert Einstein

1

1

1

1

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

5

5

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

2

2

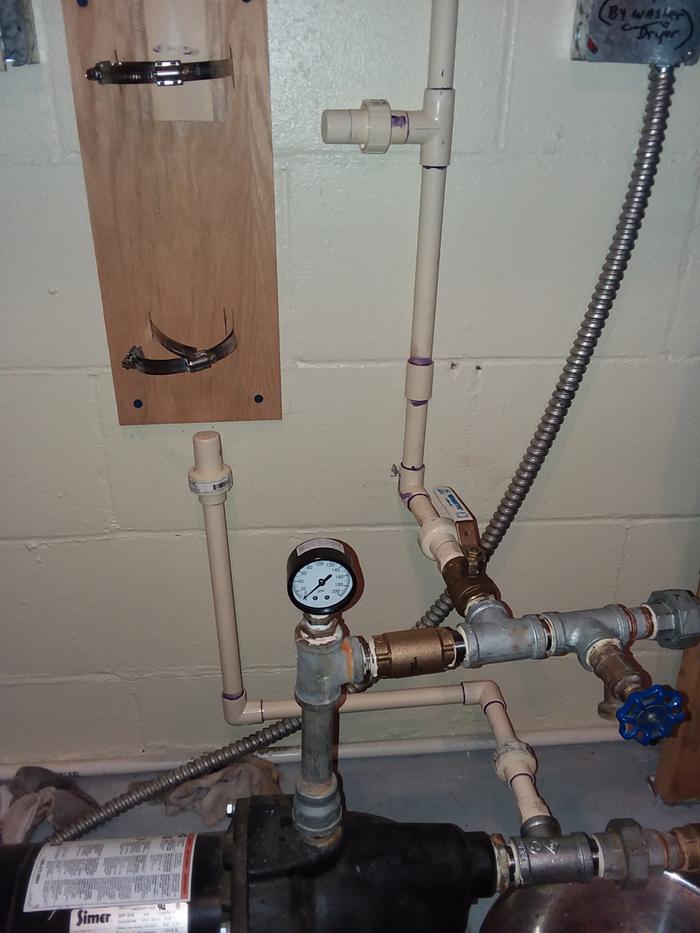

Mike Haasl wrote:So in the morning I'll pick up a ball valve to replace the check valve. Then if the power's out I just have to close that valve to use the hand pump...

Nails are sold by the pound, that makes sense.

Soluna Garden Farm -- Flower CSA -- plants, and cut flowers at our farm.

3

3

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

1

1

John Daley Bendigo, Australia The Enemy of progress is the hope of a perfect plan

Benefits of rainfall collection https://permies.com/t/88043/benefits-rainfall-collection

GOOD DEBT/ BAD DEBT https://permies.com/t/179218/mortgages-good-debt-bad-debt

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

1

1

'What we do now echoes in eternity.' Marcus Aurelius

How Permies Works Dr. Redhawk's Epic Soil Series

1

1

Mike Haasl wrote:Ok, I thought I knew what I was doing... I am adding a hand pump to my house plumbing so that if the power is out I can still pump water from my shallow (sand point) well.

“The most important decision we make is whether we believe we live in a friendly or hostile universe.”― Albert Einstein

2

2

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

1

1

John Daley Bendigo, Australia The Enemy of progress is the hope of a perfect plan

Benefits of rainfall collection https://permies.com/t/88043/benefits-rainfall-collection

GOOD DEBT/ BAD DEBT https://permies.com/t/179218/mortgages-good-debt-bad-debt

2

2

2

2

1

1

I want to be 15 again …so I can ruin my life differently.

4

4

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

|

Watchya got in that poodle gun? Anything for me? Or this tiny ad?

permaculture bootcamp - gardening gardeners; grow the food you eat and build your own home

https://permies.com/wiki/bootcamp

|