tom Brue wrote:Is anyone using solar dehydrators in the gulf coast or other very humid areas? I saw mention on one of the radiant heat designs (black metal over single layer trays) about the high humidities in the Midwest. Down here is Houston, the humidity is almost always around 80% or more. If you walk outside and the humidity is oddly low, it's a miracle blessing! Those are "sick" days from work!

Anyway, would the solar driers work if the incoming works ready 80-90% saturated? Would they just be less efficient? Or not dry fast enough? I'm wondering if it's even worth building one here.

Please, Gulf States cooks and gardeners, or those from the humid Southeast, reply with practical tips!

Do you dehydrate? Does dehydrated food keep, or do you have to seal or freeze it afterwards anyway?

If you currently keep and use dehydrated foods such as raisins, sundried tomatoes, tomato paste, etc, and you grow these foods in your garden, then it might be worth doing a solar dehydrator to produce your own.

What follows here is speculation, as I've spent most of my life in Western states with dry summers.

We often get summer relative humidity below 10%, rising to above 25% only at night, which creates extreme fire danger. But food dries pretty darn quick no matter where you put it.

In winter, the same west-coast climates typically have 75% to 100% humidity. Keeping buildings, clothing, and dehydrated food from going moldy requires good design for ventilation, air-sealing during summer, and/or supplemental or passive-solar heat.

You can affect humidity by heating the air.

When air gets warmer, all other things being equal, the relative humidity should decrease. (the gulf heating up and releasing more moisture into the air in summer is the sort of thing that is not "equal" everywhere.)

The question is: how hot would you need to get your air in order to have a low enough humidity to dehydrate the food?

To deal with your humid climate, you will basically be cooking your foods hotter while drying them. Herbs can be more sensitive to heat than, say, tomatoes or meat jerky.

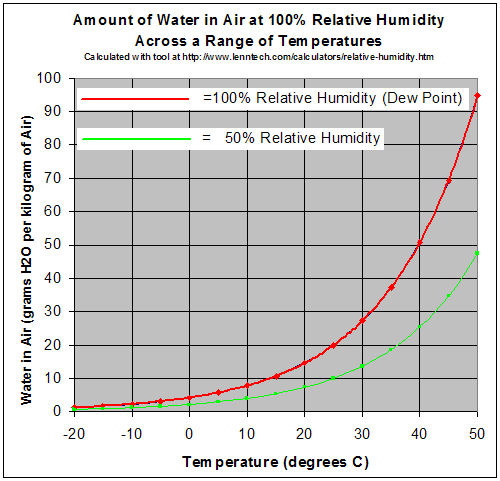

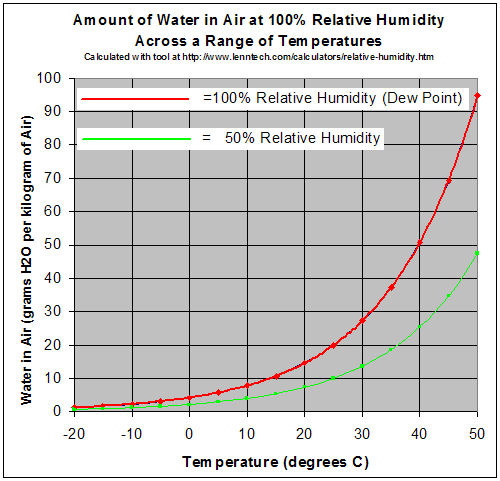

Here's a graph showing how much water is in the air at 100% and at 50% relative humidity.

Citation: "Relative Humidity" by English Wikipedia user GregBenson. Licensed under CC BY-SA 3.0 via Wikimedia Commons -

http://commons.wikimedia.org/wiki/File:Relative_Humidity.png#/media/File:Relative_Humidity.png.

To take an example temperature that most of us have experienced, 80 F would be 27 C, or so.

30 C is about 86 F.

40 C is 104 F, fever temp, a warm-ish bath, or time to find some shade to avoid heatstroke. (Hot bath might be 110 F / 45 C).

50 C is 122 F, a safety threshold to avoid scalding for tap water; for dry surfaces it's hot but comfortable to touch; as a weather condition it could be lethal to be outside too long.

60 C would be 140 F, quite hot, and above about 65 C / 150 F it's too hot to touch.

... You are in some danger of burning or caramelizing things if they bake long enough at these temps.

100 C is 212 F, the boiling point of water. Wet foods like soup or paste won't burn at this temp

as long as they remain wet, but the edges of uneven-thickness pieces could carmelize or degrade if they stay this hot after they are mostly dry.

Most ovens bake at 300 to 450 F, or 150 to 230 C. Expect browning and softening of cell structures at these temperatures; herbs will lose color and flavor, but other foods may concentrate and sweeten.

Hold a ruler or bookmark up to make a horizontal line along the graph.

If you were 100% humidity at 27 C (80 F), then you raised the temperature of that same air to 40 C (104 F), you'd be less than 50% humidity. If you can raise it further, to 50 C (122 F), you'd be at less than 25% humidity if I'm reading the graph right. Most things will dehydrate under those conditions, with enough air movement.

However, a dehydrator that gets to 120 F on a hazy day when it's 80 degrees out could become dangerously hot on a sunny day when it's 105 F to begin with. I might think about including a reflector (like those car window-shades) to block some sun from the dehydrator as needed.

Other tricks for high-humidity situations:

Physical or chemical moisture absorbers:

A friend with leaky car windows kept a bag of cat litter in her car to help de-fog the windows in our rainy season.

(Clean, unused, bentonite clay cat litter without perfumes and dyes. Pond, well, and oil-drilling companies also use a rougher grade of bentonite clay for their processes if cat litter squicks you out.)

Rock salt will also absorb some humidity, though it's more corrosive to store. There are chemical dehumidifiers that absorb even more.

When the clay or salt is too moist to be useful any more, you can dry it again in a kitchen oven or solar oven to drive off the moisture and re-use it. (Don't try this with chemical dehumidifiers unless they come with instructions to do so.)

A bag or tray of cat-litter in the air intake, to absorb moisture from incoming air before it is heated, could be enough to get good results from any common dehydrator design.

Air movement helps - if the same air remains over wet food and doesn't move, it will get saturated with moisture and no more water will evaporate. But if the air is already saturated, the same thing happens. Changing the temperature of the air helps adjust the saturation, but air movement will generally make a bigger difference than temperature once it's working at all. Most of the successful designs include a lot of air movement. At your working temperatures, expect the hot air to continue moving upward even while collecting moisture from the food. Consider a bigger solar chimney to accelerate air movement - this might help protect food from burning by letting you keep the temps a little lower while removing moisture faster.

Freeze-dried air - if you have a way to cool the air, so it can't hold as much moisture, then warm it back up, you can get the same de-humidifying effect at lower temperatures. Some foods will readily dehydrate in the freezer; if you can seal them well enough to avoid off flavors, you might get better results in the freezer than outdoors. An indoor dehydrator that takes advantage of air-conditioned air could also be an asset - maybe consider putting your dehydrator next to the air outlet vents from your house, if you use AC. (If you dehydrate indoors your AC would have to work harder, just like it does when you cook or make sauces indoors. But it could still be a tactic worth considering if the food is delicious enough to justify indoor cooking.)

Likewise, your dehydrator might work better in winter, when air temperatures and total moisture content of the air is lower.

Surface area: if you are able to get successful but slow dehydration, cutting the food smaller or drying thinner layers of pastes will increase the surface area and help speed moisture removal. Consistent size chunks will also help things dry at the same rate. It's easy to burn the edges, or the thin spots on a tomato slice, when drying with higher temperatures.

Is it worth it?

What would you be gaining from doing this?

I spent a couple months in San Antonio last year (August-October), and had a tiny cupboard and a single fridge drawer to cook from. We had to check the cupboard frequently to eliminate spoiled foods.

Storing dehydrated foods may be an even bigger concern than passive dehydration - if you just leave them out, they'll go moldy or slowly

compost.

Glass jars might work if you get the moisture low enough, or you might add salt or sugar or smoke to deter molds and insect pests. I brought some dehydrated tomatoes from home in Zip-loc bags and they stored fine for a month or more.

If you are going to have to pressure-can or freeze the food to keep it, it might not be worth doing the separate step of dehydrating, except to make foods you really like or to reduce your storage volume. Canning in an outdoor kitchen might be more effective for bulk storage, and you might want to save up for emergency power to keep the fridge or freezer running.

However, if I was living from the garden and wanted to keep my fuel needs down, I might still find it worth using a solar dehydrator or solar oven to make tomato paste, fruit leather, or fruit 'candies' like raisins, dried apricots, and dried pears. Some foods are treats when dehydrated, even if you don't dry them all the way to the crispy potato-chip-like texture that's required for preservation.

You also have the luxury of growing more foods year-round than some of the northern climates, so your total volume of preserved food doesn't need to be as much. You might be able to do a smaller dehydrator and use it indoors.

If you do try it, please share the results!

Yours,

EKW

1

1

.

.  1

1

1

1

1

1

.

1

1

2

2

2

2

![Filename: RelativeHumidity-27C.png

Description: Modified drawing- Relative Humidity graph with 27 C marked out. [Thumbnail for RelativeHumidity-27C.png]](/t/21134/a/28364/RelativeHumidity-27C.png)