2

2

1

1

1

1

Glenn Herbert wrote:The three-stone fire has been used forever, so longevity is not necessarily an indicator of efficiency. It is an indicator of effectiveness, sometimes in spite of drawbacks like pollution.

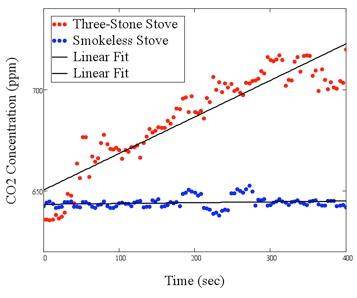

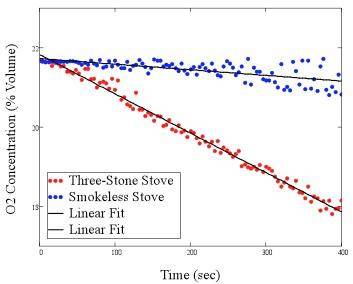

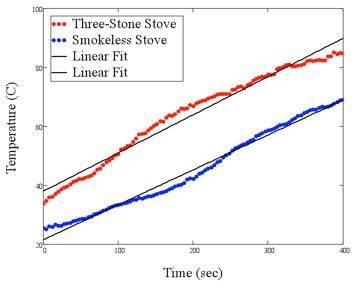

I don't see what relevance the comparative O2 and temperature graphs have in the MIT case... more info is needed to tell that. The CO2 concentration is nowhere near as low as the batch boxes that have been tested recently, which is an indicator of less than complete combustion. No visible smoke does not mean no smoke.

5

5

2nd to last paragraph-last sentence.Aaron Festa wrote:"I'm going back to simpler designs that do the same with out the issues.". Can you please elaborate and show us your specific build/design?

1

1

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

2

2

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

1

1

"You must be the change you want to see in the world." "First they ignore you, then they laugh at you, then they fight you, then you win." --Mahatma Gandhi

"Preach the Gospel always, and if necessary, use words." --Francis of Assisi.

"Family farms work when the whole family works the farm." -- Adam Klaus

William Bronson wrote: Metal stove pipe riser?

And it failed. Go figure.

I could post a bunch of videos showing failures of other stoves or long term success in rocket builds but I don't think that doing so will serve any useful purpose.

5

5

1

1

And build a beast or three outside and once you get a really good rocket stove design, start trying the other builds you wish to compare to it. Unless you have thousands of dollars for a Testo or similar gas analyser, there's only so much you will be able to measure. I do not know of a cheap and effective gas analyser, although that would be great!

And build a beast or three outside and once you get a really good rocket stove design, start trying the other builds you wish to compare to it. Unless you have thousands of dollars for a Testo or similar gas analyser, there's only so much you will be able to measure. I do not know of a cheap and effective gas analyser, although that would be great!

1

1

Glenn Herbert,

The fact that inflated or uneducated or unsupported claims have been made for RMHs does not invalidate the sober research and development that has been done on them, nor do the misled experiments posted on youtube.

~~~~~~~ snip ~~~~~~~

Yes, these will destroy metal, which is why metal is not used in durable builds by people who know what they are doing, but firebrick is very durable, and with matured practices the typical RMH might come to be designed like some masonry heaters, with a lining of firebrick at the highest-wear areas that is There is still research to be done.

Mistaken claims of metal "melting" temperatures aside, metal does distort and/or degrade at the reported temperatures in the presence of oxygen or combustibles. So nobody who knows what they are doing uses it in these areas. The reason there are so many failures is that this is a relatively new (to us, anyway) area with a lot of non-professionals experimenting. Some of them may hit on real improvements. Some already have. There are many, not just some, RMHs that work very well, and deliver heat with radically less wood than established technologies. That is a real-world measure of efficiency.

2

2

(go to about the 20 minute mark, and it's mentioned at 23:45 I think... But watch from 20:00. Their discussing the riser)

(go to about the 20 minute mark, and it's mentioned at 23:45 I think... But watch from 20:00. Their discussing the riser)

I found it in less than 24hrs once looking at inverted flue designs of the past. I knew all this was old, had been done before and someone might have left or wrote an Instructable. All, is not on the net, but some of it is... you just have to look for it.

I found it in less than 24hrs once looking at inverted flue designs of the past. I knew all this was old, had been done before and someone might have left or wrote an Instructable. All, is not on the net, but some of it is... you just have to look for it.

chase canadé wrote:

Which brings me back to the RMH...And that ugly ass 55 gallon drum. It's just got to go. Someone has to come up with something that looks like it belongs in the living room and not in a gas station work bay. A decorative box around it, something. Anything.

Just because is made out of recycled or waste materials, doesn't mean it has to look like it is.

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

2

2

1

1

“The most important decision we make is whether we believe we live in a friendly or hostile universe.”― Albert Einstein

John Weiland wrote:If you are looking for the ultimate permanence and performance in the unit, build it out of kryptonite, stoke it with di-lithium crystals, and give it the name "Messiah".

4

4

2

2

9

9

I'm going to have to respectful disagree with you

And I questioned myself, "what if everyone had one of these RMH's of rocket stoves?"

The answer is we'd be in serous trouble all over again. The planet especially.

The problem is more basic. Those burning wood as a primary fuel source need to be shown a new better solution.

CO2 is a major problem. We need all the plant life we can get.

And this is not to say the rocket stove or RMH isn't a valid technology worth noting and has use. But it does, in my conclusion, more harm than good.

There are more passive ways

2

2

1

1

"Never doubt that a small group of thoughtful, committed citizens can change the world; indeed, it's the only thing that ever has."-Margaret Mead "The only thing worse than being blind, is having sight but no vision."-Helen Keller

1

1

chase canadé wrote:@ Paul,

And someone stated, "this is not permiculture" and... their right.

- chase -

Freakin' hippies and Squares, since 1986

paul wheaton wrote:

In the meantime, for a conventional home, NOTHING beats a rocket mass heater for sustainability and what is better for pollution problems. NOTHING. You wanna do passive solar or a wofati, or AGS or PAHS etc. That requires building a whole new house.

You don't necessarily need to build a new house to save the planet

You don't necessarily need to build a new house to save the planet

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Living in Anjou , France,

For the many not for the few

http://www.permies.com/t/80/31583/projects/Permie-Pennies-France#330873

1

1

And this is the last we ever heard from this guy. A few years later, we created the "rocket mass heater myths" series: https://permies.com/t/72557/rocket-mass-heater-myths-youtube

David Livingston wrote:Antone

But you can have a straw roof ? in French -Chaume or as we say in English Thatched rooves

I agree about new vs old houses . I find here in France the availability of old solid houses built to last as opposed to new timberframed frankly wooden tents that I give 50 years max very interesting .

David

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

|

If I'd had more time, I would have written a shorter letter. -T.S. Eliot such a short, tiny ad:

New Year, New Earth Summit - register for free!

https://permies.com/t/367268/Year-Earth-Summit-register-free

|