11

11

The first 8 or so posts here were copied off another thread, as it's a VERY interesting concept and wants to be discussed more.

Conversation started HERE https://permies.com/t/40/190249/heat-supply-chains-break#1571756 ; if you want the context.

4

4

jack vegas wrote:What about putting together a "Biomeiler" or compost heater? These can be built relatively inexpensively and quickly and will produce useful heat for several months. Just about any organic material can be used including wood chips, tree leaves, manure, tree trimmings, and yard waste. Unlike burning wood products, the fuel doesn't need to be dry. In fact, it needs to be wet! Also, relative to combustion devices, there is much less or even zero concern about permitting, insurance, certifications, and environmental regulation. I suspect usable fire wood might be in short supply as everyone looks to it as an alternative fuel. Far fewer people will be competing for organic waste products. Even if you can't produce all the heat you need it might significantly reduce the amount of additional heat needed from conventional sources.

Blazing trails in disabled homesteading

9

9

4

4

7

7

jack vegas wrote:Several years ago I built a very small indoor "pile" in a 55 gallon steel drum. It had a small computer fan to circulate fresh air and the exhaust was dumped through the kitchen ceiling fan vent. An automotive electric window motor was used to rotate the drum periodically to keep all material inside uniformly damp and break up any clumps. All this was enclosed in a box made of 2" foam insulation that allowed heat to build as the bacteria did its work. The heat produced soaked through the steel drum and heated the air inside the box. Once the temperature inside the box exceeded 130 deg-F a fan pulled air through the box and dumped the heated air into the room. If the box exhaust temperature dropped below 120 deg-F, the fan cut off. I kept it running continuously by feeding organic material daily. It actually worked relatively well and kept the house temperature between 55-60 deg-F. During the day I augment with electric heat.

jack vegas wrote:A more powerful "pile" that I'm considering building this winter would be contained in an insulated box 4 ft x 4 ft x 8 ft long that will sit in my backyard. No mechanical devices this time, just an insulted box filled with organic material. It will have two rods running through it with paddles welded along their length that I can hand crank periodically to stir the contents. This will be a closed box, painted to match my house and I doubt if anyone will notice or complain. Local regulation allow an un-permitted shed up to 120 sqft so I don't think this will break any codes and certainly no HOA regs (we have a few but sheds and even compost piles are allowed). I really think this is an approach that could work for just about any suburban house without raising many eyebrows. I'm hoping it will produce enough heat over 4 months to keep the house interior above 60 deg-F. If it does, sun on the house should raise daytime temperatures well above 65 deg-F.

jack vegas wrote:As might be noted, I'm not a fan of the Jean-Pain-style "pile."

Douglas Alpenstock wrote:This would make a great stand-alone thread though.

Blazing trails in disabled homesteading

4

4

Matthew Nistico wrote:

jack vegas wrote:First, my frame of reference - I live on a remote part of the Washington coast in a poorly insulated 750 sqft cottage on 1/4 acres in a small community of maybe 30 other houses. Outside city limits but within county jurisdiction where building and health codes are enforced. Winter temperatures are generally between 20 and 40 deg-F. Certainly not as cold as Germany (spent 3 wonderful years there when I was a kid) but cold enough.

I'm imagining several of these set up and running at once, one in each room perhaps, and I'll bet you'd need no other heat source in any decently-insulated, weather-proofed home. The only downside is the amount of square footage sacrificed. There is also some minimal daily maintenance (feeding more organic matter to the digester), though that would certainly be equal or less than the time needed to tend a woodstove.

Blazing trails in disabled homesteading

1

1

Matthew Nistico wrote:Still, I can imagine no social value from sitting around watching the compost digest.

5

5

Douglas Alpenstock wrote:

Matthew Nistico wrote:Still, I can imagine no social value from sitting around watching the compost digest.

Hahaha!

“The most important decision we make is whether we believe we live in a friendly or hostile universe.”― Albert Einstein

5

5

John Weiland wrote:

Douglas Alpenstock wrote:

Matthew Nistico wrote:Still, I can imagine no social value from sitting around watching the compost digest.

Hahaha!

On the other hand, if Dr. Doolittle could 'talk to the animals', perhaps this would be that golden opportunity to learn how to 'converse with the microbes'!

5

5

Gardens in my mind never need water

Castles in the air never have a wet basement

Well made buildings are fractal -- equally intelligent design at every level of detail.

Bright sparks remind others that they too can dance

What I am looking for is looking for me too!

4

4

sow…reap…compost…repeat

4

4

Visit Redhawk's soil series: https://permies.com/wiki/redhawk-soil

How permies.com works: https://permies.com/wiki/34193/permies-works-links-threads

4

4

Jay Angler wrote:I've been trying to come up with a urine system that will work - sawdust barrel with mostly urine added? I'm not sure compost really works when it's just wood carbon and nitrogen and little else.

Jay Angler wrote:So the question becomes, would the barrel idea work with just sawdust and some urine added on a daily basis? Would enough composting happen to create warmth? Would it just turn into a stinky mess? Is my thinking right that it would work better if the compost was damp to begin with?

Blazing trails in disabled homesteading

Blazing trails in disabled homesteading

7

7

1

1

3

3

3

3

jack vegas wrote:Digesters aren't easily throttled. The oxygen supply can be restricted somehat to slow things down, but generally they are either on or off, and if they are off, they usually need a couple days to get back up to temperature.

Blazing trails in disabled homesteading

6

6

2

2

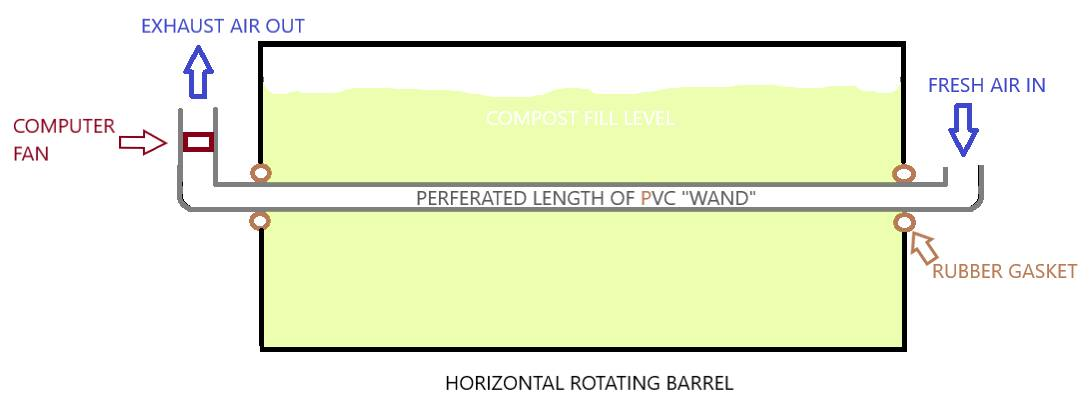

jack vegas wrote:I put together a more complete description of my "Barrel in Box" compost reactor to help people understand how it was built and how it worked.

Physical description with reference to the attached drawing:

The core of the unit is a 55 gallon steel drum with a removable head to facilitate loading and clean out.

Blazing trails in disabled homesteading

1

1

1

1

1

1

1

1

Lif Strand

New Mexico USA

1

1

2

2

2

2

Hans Albert Quistorff, LMT projects on permies Hans Massage Qberry Farm magnet therapy gmail hquistorff

5

5

1

1

jack vegas wrote:Rotating drum - many desirable mechanical adaptations were not possible due to the drum rotation and particularly due to the PVC pipe "wand" down its core. At first I thought the wand was a pretty clever way of solving the rotational seal problem, but it prevented filling the drum more than about 40 % full due to leakage through the gap between the drum and pipe. I'm fixed on the rotisserie approach because I think it does the best job of maintaining moist material and breaking clumps. I've considered internal paddles but power requirements to push material with paddles could be excessive. In my ideal design I'd use a stationary vertical drum, but I've never been able to adequately address all the issues to my satisfaction with that configuration.

jack vegas wrote:Feeding - As described above, it was tedious, required breaching the thermal cocoon, and it meant dumping a lot of cold material into the drum all at once. Ideally there should be a way of feeding small quantities of fresh material frequently or even continuously without breaching the thermal cocoon. Since a lot of my experimentation used wood pellets I considered a pellet feed setup similar to a pellet stove. That could probably be achieved but it would preclude using wood chips or yard waste. Wood chips are very inexpensive where I live and I can get large quantities free in the fall from tree trimming services. I also have a surprisingly large amount of yard waste on my property that I'd really like to use since I put so much effort into cutting it back in the fall.

jack vegas wrote:Clean-out at the end of a run was a pain. I'd remove the box, withdraw the wand, then tilt the drum up onto its sealed end. After that it was a simple job of rolling the drum outside on a hand truck, dumping the residue in the garden and hosing it out. The pain was disassembling the unit to get to the drum. I'm older now (72) and it would be neat to find a way of only handling the residue and not the whole drum. I keep noodling on ways of cleaning it out like a wood stove... except in this case the ashes would be moist soil that doesn't blow around!

jack vegas wrote:Using wood pellets I could load 40-50 lb of pellets and once running well they were consumed at a rate of about 1 lb/hour. This works out to an equivalent of about 8,000-9,000 Btu/hr depending on fuel quality. If I could have filled it more than 40% full I feel I could have pushed output to 15,000 Btu/hr.

Blazing trails in disabled homesteading

Hans Quistorff wrote:A lot of the complexity is unnecessary if it is to heat a greenhouse. I see using one of my old barrels that is solid on the sides but the bottom is rusted out. What water that comes out the bottom screen goes into a planting bed soil. It will replace one of the water filled barrels used for passive heat storage. The lid will be the top of a plastic barrel which I use for seed starting so the soil needs to be kept warm. I will screw in plastic pipes in the bung holes to let the air exit the top of the barrel. I will be using my riding lawn mower to gather leaves as they fall and dry grass from the field for fuel and add urine for nitrogen along with the wood based cat litter. Probably will put it between 2 water filled barrels and log the temperature of the 3 barrels while I am logging the high/low thermometer each day.

Lif Strand

New Mexico USA

2

2

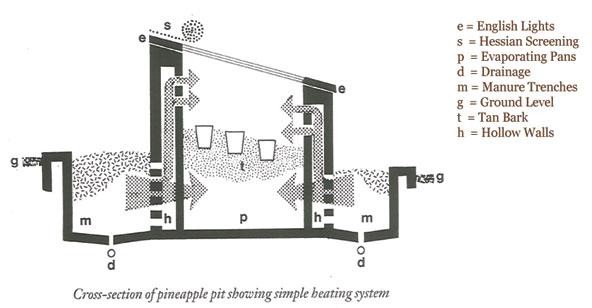

Joe Grand wrote:I found this same time ago, hope it is of some help:

The Victorian method of growing pineapples...

Lif Strand

New Mexico USA

1

1

2

2

Lif Strand wrote:

Joe Grand wrote:I found this same time ago, hope it is of some help:

The Victorian method of growing pineapples...

I found a webpage with a cross-section diagram for a pineapple pit at the Lost Gardens of Heligan https://www.heligan.com/news/the-story-of-the-10000-pineapple The equivalent of the $10,000 tomato that I'm so familiar with! Actually, that design looks basically like what I tried with my "bedroom" horse trailer. For it to work, though, there has to be lots of hot (freshly pooped) horse manure, and that means replacing cooked-out manure with freshly pooped, which would be a tough job if done by hand. I suppose the troughs for the manure could be constructed just wide enough to get a garden tractor with a blade in it.

Pineapple pit cross-section

Brick pineapple pit[/url]

I'm now musing on the idea of a long "pineapple pit heater" trough that butts up against my house, which is on short piers. I'm a low-tech kind of person due to my low skill-levels, and I'm also always looking for solutions that don't require additional power (I'm totally off-grid), so the pineapple pit idea seems like a real possibility to me.

1

1

to help keep the pile from clumping???(please clarify on this point, I’m not really sure what causes the clumping). You can put in a drain off valve, so you can easily drain off the moisture any time it becomes necessary.

to help keep the pile from clumping???(please clarify on this point, I’m not really sure what causes the clumping). You can put in a drain off valve, so you can easily drain off the moisture any time it becomes necessary.

2

2

Hank Fletcher wrote:Third, what does turning the pile actually do for the pile? Does it keep it from clumping up? Does it matter if it clumps up or not? Does turning the pile aerate the pile? Is it the aeration that matters or what matters most in turning the pile in keeping the pile working and keeping it producing the temperature output?

Hank Fletcher wrote:Think something like this, no drawing programs so I’m doing it crudely.

Hair dryer or computer fan to inject the heat down the PVC pipe

| |

| |

|---------------------------------------| screen to keep leaves/chip/pellets from blowing out when air is applied

| | | perforated |

| | | 1/2-2” |

| | | PVC |

| | | |

| | | |

| ============== | perforated PVC running sideway through the pile

| | | |

| | | |

| | | |

| ============== | perforated PVC running sideway through the pile

| | | |

| | | |

| | | |

| ============== | perforated PVC running sideway through the pile

| | | |

| | | |

| | | |

| ============== | perforated PVC running sideway through the pile

| |

|--------------------------------------| screen to allow the liquid to run down to the bottom of the bucket/drum

| |

| |\

|______________________________|\ \

\ \ drain plug to drain off the liquids

The drain plug could also be something as ease a hole in the bottom of the bucket which could drop right down into a container on the floor. This would eliminate any need for any kind of plumbing valve. Also as I mention, in questioning down below(rereading and editing this as I go) you could drill several holes in the sides of the bucket, down below the screen mesh to get rid of the CO2, or is it heavier than air, at which it would be gotten rid because you no have lid on top of the bucket/drum.

Blazing trails in disabled homesteading

Matthew Nistico wrote:...And you would likely want to incorporate some other features of Jack's from that diagram, like a way to selectively turn the heating element inside the forced-air-hair-drier on or off as necessary, based on a thermostat reading of the barrel's internal working temperature.

Blazing trails in disabled homesteading

1

1

![Filename: temp-controller.jpg

Description: [Thumbnail for temp-controller.jpg]](/t/190818/a/188998/temp-controller.jpg)

| I agree. Here's the link: http://stoves2.com |