8

8

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

12

12

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

7

7

Welcome to the serfdom.

3

3

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

6

6

Visit Redhawk's soil series: https://permies.com/wiki/redhawk-soil

How permies.com works: https://permies.com/wiki/34193/permies-works-links-threads

6

6

A company on Vancouver Isl uses a chain saw (don't know if it's some sort of special one) and cuts a wedge out of the upper log and fills it with insulation (I think they were using artificial stuff). They didn't alter the lower log, but left it round. As you say, 2 round logs make for difficulty getting insulation to stay put very well. However Jeff Steez's point of not wanting moisture to pool also makes sense to me.Build the walls by laying the logs on top of each other (like normal). Use natural chinking between the logs, only since you cut flats on them, they have a fair bit of flat surface area to sandwich the chinking.

Visit Redhawk's soil series: https://permies.com/wiki/redhawk-soil

How permies.com works: https://permies.com/wiki/34193/permies-works-links-threads

5

5

6

6

Whoah!! Check out this permie deal!! https://permies.com/w/homesteading-bundle?f=232

"The only thing...more expensive than education is ignorance."~Ben Franklin. "We can easily forgive a child who is afraid of the dark; the real tragedy of life is when men are afraid of the light." ~ Plato

9

9

Welcome to the serfdom.

5

5

John Daley Bendigo, Australia The Enemy of progress is the hope of a perfect plan

Benefits of rainfall collection https://permies.com/t/88043/benefits-rainfall-collection

GOOD DEBT/ BAD DEBT https://permies.com/t/179218/mortgages-good-debt-bad-debt

4

4

yet another victim of Obsessive Weeding Disorder

7

7

2

2

6

6

"If you always do, what you always did, you'll always get, what you always got!" Mike S.

"It's easy to chop out excess trees. It's really hard to get a mature tree today." Joseph Lofthouse

2

2

Thomas Michael wrote:Mike: in Alaska at a weekend show I saw a log cabin built out of 2 flat 4x3x8 garden timbers. They built it butt and pass an put a 3inchx1/4" close cell foam strip between the log layers. I think it was a floor pading for a floating engineered floor system. Made a neat little garden shed / ticket booth. I remember doing the math and it was about 70% the cost of stick and plywood shed $, and self standing, no floor on the asphalt parking lot. Tom

Become extra-civilized!

3

3

Rez Zircon wrote:So about logs cut flat for the chinking... seems to me if you can cut them so they lie at a little angle, any water that gets in will run back out. It's not getting wet that's an issue, it's staying wet.

Become extra-civilized!

3

3

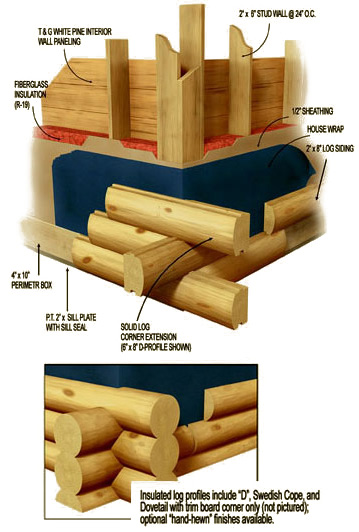

Steve Zoma wrote:If a person is going to do that, why not just frame the walls conventionally, and then put log siding on the outside (2 inches thick) and then pine on the inside? No drafts, R-19, standard thickness walls for standard windows, wiring that is easier to do, no settling, additions can be added at a later date that is easier to do, etc,

Become extra-civilized!

4

4

Coydon Wallham wrote:

Thomas Michael wrote:Mike: in Alaska at a weekend show I saw a log cabin built out of 2 flat 4x3x8 garden timbers.

Is that "2" a typo?

If butt and pass is what it sounds like, did they have anything securing the logs to the ones above and below them besides weight? Jenga?!?

"If you always do, what you always did, you'll always get, what you always got!" Mike S.

"It's easy to chop out excess trees. It's really hard to get a mature tree today." Joseph Lofthouse

3

3

Coydon Wallham wrote:You mean if a person is going to use styrofoam like your uncle? I think mikes idea is based on the premise of using as many local/natural materials as practical.

6

6

"Ah, but a man's reach should exceed his grasp,

Or what's a heaven for?"

Andrea del Sarto by Robert Browning

10

10

4

4

Eino Kenttä wrote:Okay, that book does look interesting, but there is one very big omission in the project Jeff showed (unless it's mentioned somewhere I couldn't see). A roof like that would traditionally always have a few layers of overlapping sheets of birch bark below the sod layer, as a water barrier. Without this, the roof will leak badly, and rot quickly.

The birch bark is waterproof and pretty much never rots, but doesn't handle UV light very well. So, the sod provides insulation and protects the birch bark from light, while the birch bark stops the inhabitants from getting wet...

Become extra-civilized!

4

4

2

2

Thomas Michael wrote:

Coydon Wallham wrote:

Thomas Michael wrote:Mike: in Alaska at a weekend show I saw a log cabin built out of 2 flat 4x3x8 garden timbers.

Is that "2" a typo?

If butt and pass is what it sounds like, did they have anything securing the logs to the ones above and below them besides weight? Jenga?!?

Not a typo top and bottom flat as Mike described in the first post.

Become extra-civilized!

8

8

Coydon Wallham wrote:Have you seen that topic described in any other books or websites?

"Ah, but a man's reach should exceed his grasp,

Or what's a heaven for?"

Andrea del Sarto by Robert Browning

9

9

"Ah, but a man's reach should exceed his grasp,

Or what's a heaven for?"

Andrea del Sarto by Robert Browning

7

7

"Ah, but a man's reach should exceed his grasp,

Or what's a heaven for?"

Andrea del Sarto by Robert Browning

12

12

"Ah, but a man's reach should exceed his grasp,

Or what's a heaven for?"

Andrea del Sarto by Robert Browning

10

10

Kevin Olson wrote:Actually, I suspect if you had an entire structure worth of left hand twist logs, it wouldn't matter so much, but mix-n-match is potentially a bad combo with the twists working against each other, and since most logs are somewhere between straight (minimal twist) and right hand twist (for whatever reason, the chirality is preferentially right handed), avoiding left twist logs can help prevent tortured walls and drafty buildings.

"Ah, but a man's reach should exceed his grasp,

Or what's a heaven for?"

Andrea del Sarto by Robert Browning

6

6

Kevin Olson wrote:

Having only just recently received my copy, I can report that Robert Chambers, in his "Log Construction Manual" book, asserts that all needle leafed (coniferous) young trees have left hand twist, but that most gradually acquire a right hand twist as they get older. He also asserts that this is genetically determined (nature, not nurture). Those trees which do not change "handedness", and remain left hand twist later in life, are much weaker in bending, per Chambers. He also claims that the lower trunk of a tree may have right hand twist, and the upper portion (crown) left hand twist, due to the younger age of the crown. He also says that left hand twist logs will twist more as they dry to equilibrium moisture content, whereas right hand twist logs will be more stable (presumably due to the inner and outer twists counteracting each other - also why the bending strength would be improved, I suppose).

Become extra-civilized!

4

4

Coydon Wallham wrote:

Does he explain the environmental conditions that cause this "twisting"? I'm thinking of something like sunflowers following the sun's track, but that wouldn't seem to make sense for a tree. Any idea if trees raised in plantation settings would be more or less likely to develop those characteristics?

Become extra-civilized!

7

7

Coydon Wallham wrote:I just read the linked article- some speculation about Coriolis effect but no solid answer.

I do have Dire Straits "Twisting by the Pool" stuck in my head now, thank you very much...

"Ah, but a man's reach should exceed his grasp,

Or what's a heaven for?"

Andrea del Sarto by Robert Browning

7

7

Coydon Wallham wrote:Have you seen that topic described in any other books or websites?

"Ah, but a man's reach should exceed his grasp,

Or what's a heaven for?"

Andrea del Sarto by Robert Browning

6

6

Mike Haasl wrote:I have a weird idea for a way to build a log cabin. Take the logs and run them through a bandsaw mill to take opposing slabs off of them. Make them all either 10", 12" or 14" thick (depending on your log sizes).

Build the walls by laying the logs on top of each other (like normal). Use natural chinking between the logs, only since you cut flats on them, they have a fair bit of flat surface area to sandwich the chinking. Do whatever corner connections you want.

This seems like a simple way to build a log cabin that gives you a broad chink area for less air infiltration. One downside is you're limited to the length of the sawmill.

One possible downside is that the logs may twist between when they're cut and when you build the cabin? I'm very curious if that would be likely. I'm thinking, for my area, red pines would be the ideal species.

Thoughts?

Become extra-civilized!

6

6

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

5

5

Mike Haasl wrote:Alternately you could splice two logs together with a scarf or spline joint of some sort.

"Ah, but a man's reach should exceed his grasp,

Or what's a heaven for?"

Andrea del Sarto by Robert Browning

6

6

Coydon Wallham wrote:I thought an Alaskan style mill might be workable for this, but shopping around they seem to max out about the same as portable bandsaw mills, well under 20'. Can they be hacked to work longer logs, or would this be a matter of hand hewing or 'freehand' chainsawing? I'm not sure if the 'spacer' method from the ProjectHighlander videos works on long logs, I'm only through the first video there...

"Ah, but a man's reach should exceed his grasp,

Or what's a heaven for?"

Andrea del Sarto by Robert Browning

4

4

"Ah, but a man's reach should exceed his grasp,

Or what's a heaven for?"

Andrea del Sarto by Robert Browning

3

3

"Ah, but a man's reach should exceed his grasp,

Or what's a heaven for?"

Andrea del Sarto by Robert Browning

|

Politics n. Poly "many" + ticks "blood sucking insects". Tiny ad:

35 Ac. Homestead for Sale - Near Roanoke, VA – Asking: $995,000

https://thehopkinsgroup.biz/?page_id=501&et_fb=1&PageSpeed=off

|