Redecorating 5 rooms

2000sqft of wall, 700+ sqft of ceiling, many doors and a heck of lot of trim

I learnt doing the

sand and

straw nest badges that Otis likes a house to be a home. When we bought this house it had been empty for three years. The previous owner kept a lot of cats and was a heavy cigar smoker. Even with my

experience completing the Nest badges I wasn’t going to remove all the filth left behind and besides, wall colour is something deeply personal and we really wanted to make this house a home.

We started with Pinterest, collecting ideas. Having lived in the tropics with very bright sunshine and white walls we decide to go for deep dark rich warming colours that wouldn’t have looked out of place in the 1850’s when our house was built. I also wanted my bedroom to be dark as I’m super sensitive to light. Dark blue sits opposite golden yellow on the colour wheel, and we had white pine boards to restore, so a perfect and harmonious match.

We both like simplicity, so rather than pick a different shade for trim, we decided to paint all the trim the same colour as the walls. It also makes painting a little easier as you don’t have to tape up edges even though we used a trim paint for the woodwork and an eggshell paint for the walls. I did wanted to strip and restore the doors but they have many layers of lead paint, so after much research and

discussions on Permies I decided to paint them and document my findings for the next owner of the house. I may revisit the doors when I have a safe space or process to remove the paint. This was also part of another Permies discussion.

My son picked a lighter blue for his room. We went for a sumptuous green blue for my wife’s office. It’s very calming and looks absolutely gorgeous.

I had another

conversation on Permies about least evil paint. I have to be practical and match reality and my wife’s wishes with

permaculture aspirations. I wasn’t going to be making my own paints this time, so I went for the best manufactured options that kept everyone happy. We settled on Clare an online only paint company.

Here’s their blurb about the paint.The big brand paint companies have eco / green lines but still produce a huge volume of toxic ick. All of Clares paints meet the same standard. And they had colours we loved.

Next up, I needed a way to easily paint high ceilings, so

I built a couple of saw horses I could use with a plank.

I did my best to keep my environmental impact as small as practical using

wood, metal and natural materials rather than plastic for paint trays, poles, rollers etc. I upcycled textiles when I need to protect floors from drips. I also bought really good quality and expensive brushes which I meticulously cleaned after ever session and are still in excellent condition.

| Room | Dimensions | Ceiling | Perimeter | Height | Wall Area |

|---|

| Master Bedroom | 15’04” x 14’08” | 225 | 60 | 10’ | 600 |

| Red Room | 15’04” x 11’00” | 169 | 53 | 10’ | 530 |

| Home Office | 10’08” x 11’01” | 118 | 44 | 10’ | 440 |

| Bedroom One | 11’07” x 8’07” | 99 | 40 | 4’ - 7’ | 240 |

| Bedroom Two | 11’08” x 8’07” | 100 | 41 | 4’ - 7’ | 240 |

For each of the five rooms I worked through the following steps:

- Assess and put together a task list

- Remove nails, hooks, door furniture etc.

- Remove cable TV cables and sockets

- Remove phone cables and sockets

- Strip wallpaper (study only)

- Remove

cast iron radiators

- Clean trim, doors, window woodwork etc.

- Use feather duster to remove all cobwebs

- Make good, filling and sanding all dinks, holes, cracks

- Remove doors - left on until after sanding to minimise dust spreading into the rest of the house

- Turn off electrics, remove anything attached to the ceiling -

lights, ceiling fans and smoke alarms.

- Run extension cables from another room and set up lots of clip on lights for maximum visibility

- Typically two coats on the ceiling

- Reinstall or replace lights, fans, smoke alarms, turn on electrics

- Tape ceiling edge

- Two coats on ceiling trim in the rooms that coving

- Two coats on the walls

- Two coats on remaining trim and doors

- Replace light switch and electric socket plates (this is still ongoing to due to budgetary constraints and is a being documented for a different oddball).

- Install door stops

- Reinstall door furniture

- Reinstall doors

- Reinstall radiators

- Make good on any ‘holidays’. When I was a kid helping my dad decorate, he used to call any areas where the paintwork need touching up ‘holidays’. I don’t know if it’s just my dad or it’s a generic if not slightly esoteric description.

- I was also restoring all the floors so the baseboard trim was painted and installed last.

I worked on these five rooms over an eight week period as I had to juggle lots of other priorities including:

- Relocating

- Making good at the rental property

- Restoring the floors

- Plumbing emergencies

- Feeding the family!

Paint also takes time to dry and I wanted to make sure the previous coat was bone dry first before continuing with the next task.

Here are some pictures that show the process I went through.

Research stored on pintrest

Research stored on pintrest

Study Before

Study Before

Master bedroom before

Master bedroom before

Red room before

Red room before

Bedroom 1 before

Bedroom 1 before

Bedroom 2 before

Bedroom 2 before

Saw horses

Saw horses

Making good in the red room

Making good in the red room

More making good in the red room

More making good in the red room

Making good in the master bedroom

Making good in the master bedroom

Painting coving / ceiling trim

Painting coving / ceiling trim

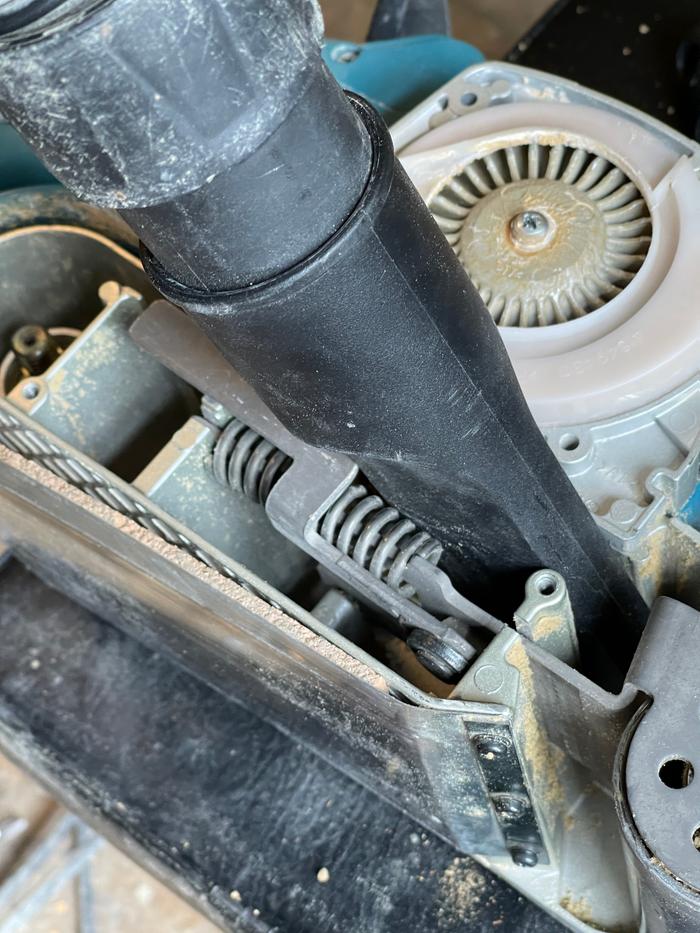

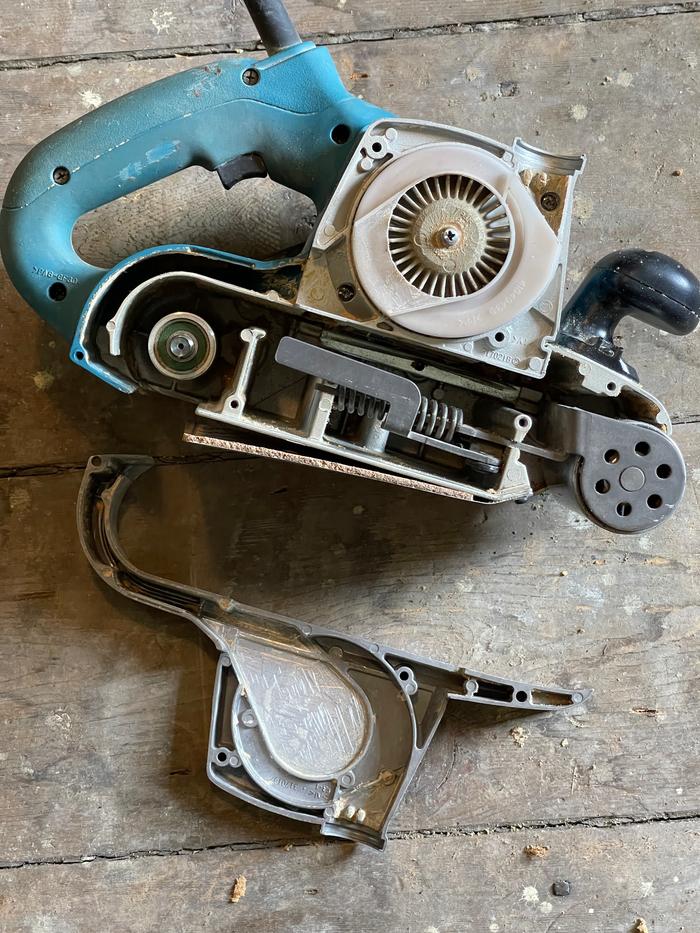

Radiator removal

Radiator removal

Ceiling fixtures removed

Ceiling fixtures removed

No more red in the red room

No more red in the red room

Bedroom one painted

Bedroom one painted

Bedroom two painted

Bedroom two painted

Study painted

Study painted

Master bedroom painted

Master bedroom painted

3

3

5

5

1

1

5

5

2

2

3

3

2

2

2

2