29

29

4

4

5

5

Like my shiny badges? Want your own? Check out Skills to Inherit Property!

4

4

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

2

2

Ashley Cottonwood wrote:Do you have any current thoughts on how best to sterilize the substrate?

Ashley Cottonwood wrote:In terms of hardwood as one of the substrates, would there be a hardwood of preference?

3

3

Mike Haasl wrote:Could they be used below grade for foundation insulation? The products available for below grade insulation are pretty limited currently.....

6

6

6

6

Mary Cook wrote:You're talking about a homestead scale operation. I'm not sure that's realistic but I'd like to see this as a small business providing perhaps a couple of local jobs. One question is whether a larger-scale factory would devour too much organic matter from the area.

5

5

7

7

6

6

3

3

4

4

Mary Cook wrote:One thing I'm wondering, You mention oyster and there is an image of Reishi mushroom spawn. But these are fruiting mushrooms...wouldn't you want non-fruiting fungi for this (is there such a thing?) I don't know that much about mushrooms, and have grown my own shiitake and oyster mushrooms with bought spawn, but that's as adventurous as I am.

4

4

3

3

Christopher Weeks wrote:It seems like the structural degradation you're talking about could actually improve the sound/heat insulating capacity if it's creating extra cavities throughout. The risk seems like it's only to the ability of the panel to remain intact.

5

5

4

4

I make a Maple Syrup instructional movie! Check it out HERE

SKIP books, get 'em while they're hot!!! Skills to Inherit Property

See me in a movie building a massive wood staircase:Low Tech Lab Movie

4

4

Mike Haasl wrote:A big hurdle for natural building is roofing materials. Might this material be a candidate for an insulated, waterproof roof? And/or in conjunction with a living roof (unlikely)?

8

8

4

4

Beau Davidson wrote:

5) Potential to include conductive metals in substrate, which may subsequently be metabolized and woven throughout mycelium structure, yielding a electromagnetically conductive building envelope to shield inhabitants from nnEMF.

Permaculture...picking the lock back to Eden since 1978.

Pics of my Forest Garden

4

4

Joshua Rimmer wrote:This is a fascinating concept! In my various construction projects are the property, insulation is always one of the biggest costs, as it can be difficult to locate recycled. I will be watching with great interest!

On a side note, how does one acquire those airline tubs? I can see many potential uses for something that size!

2

2

Greg Martin wrote:

Beau Davidson wrote:

5) Potential to include conductive metals in substrate, which may subsequently be metabolized and woven throughout mycelium structure, yielding a electromagnetically conductive building envelope to shield inhabitants from nnEMF.

Super neat project Beau! Have you seen reference to fungi metabolized metals being deposited in a metalic state for EMF shielding? If the metals were in a dry ionic state I would expect them to not be an effective EMF shield...but data is king :)

Another option if metals don't end up working may be to incorporate wood charcoal formed at 800C throughout the substrate to act as the EMF shielding. As a bonus your panels would be even more carbon negative.

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7758945/

https://www.biochar-journal.org/en/ct/3

4

4

Beau Davidson wrote:Concerning the possible use of mycelium insulation panels in a high temp environment

?

3

3

PRI PDC Grad Nov 2021

Tim Mackson wrote:

Beau Davidson wrote:Concerning the possible use of mycelium insulation panels in a high temp environment

?

I wonder if you could somehow use starlite, either mixed, or as a layer on top of your mycelium?

Cool Tim, thanks for that. I had considered various forms and mixtures of glass, silica, and clay, but not a treatment like those mentioned in these videos. Thanks for the input.

1

1

Brian Guetzlaff wrote:

For the heat riser tube (or any of the forms), how much shrinkage do you expect between the original form shape and the final result after drying? Also, as ambient moisture levels change, how do you expect the panels (or blocks, tubes, whatever) to respond? I can see how they'd either swell/shrink as a whole due to the permeability, or just on the surface (in which case the air pockets could serve as an internal buffer, giving room for the dimension changes at the surface).

If the moisture does end up staying primarily at the surface, do you expect there to be any warping or bowing effects (imagining a flat panel here).

Brian Guetzlaff wrote:

One last one for now: Is it possible to form the final products such that typical wood joinery techniques can be used to lock them together (or strategically use wood pegs to lock them in place), hopefully avoiding gaps and/or shifts due to shrink/swell? I'm not thinking these would be carved into shape, but rather pre-formed in the correct shape.

6

6

1

1

J Rubins wrote:Specifically I’m working on insulation for structures, and even more specifically for my ger/yurt.

J Rubins wrote:Project at the moment is using Pleurotus ostreatus (common oyster) but I might give Flammulina velutipes (enoki/velvet foot) a try too. I isolated a local strain here in Illinois and it is a very fast colonizer, faster than oyster and almost as quick as Morel. I’m using a mix of hardwood sawdust and straw (maybe some wood chip) for the substrate and shooting for panels 2” thick. Forms are urethane coated lumber on the base and sides, top side either polycarbonate or plastic sheet with holes spaced and covered with micro pore tape for gas exchange.

J Rubins wrote:For now I’m not planning on letting the mycelium fruit. My understanding is many in the past who are making insulation this way avoid this as it will release spores(lots and lots of them in the case of oysters). Also having done some building in the past, insulation will almost always accumulate condensation due to humidity and delta T. Water + food, substrate+ spores= renewed mushroom growth, not something too desirable in walls for me at least. My understanding is the insulation panels are also often heat-treated in order to ensure the mycelium is inactive, read dead. I believe spores are more heat tolerant than mycelium, too.The one thing about having that air mycelium skin that’s heat treated is that it is pretty hydrophobic, too, a plus, eh?

But some thoughts: there are commercial varieties of oysters I think that are low spore producers and I think some may not produce any at all ( the spores of oysters in particular can lead to growers developing lung ailments/allergies which is why such unique strains are sought after). Forgive me if I missed that detail in reading about your work so far, but it is a concern for air quality, and longevity of the insulation.

I do like the idea of first getting a crop and then getting an insulation board or infill block from that one stone thrown! Maybe those cultures are worth looking into?

2

2

1

1

Tom Philips wrote:Could you use CLO2 for sterilization instead of steam? Should be much faster and easier to get better results. It is the gold standard for water treatment, food processing, even used for Anthrax removal.

1

1

3

3

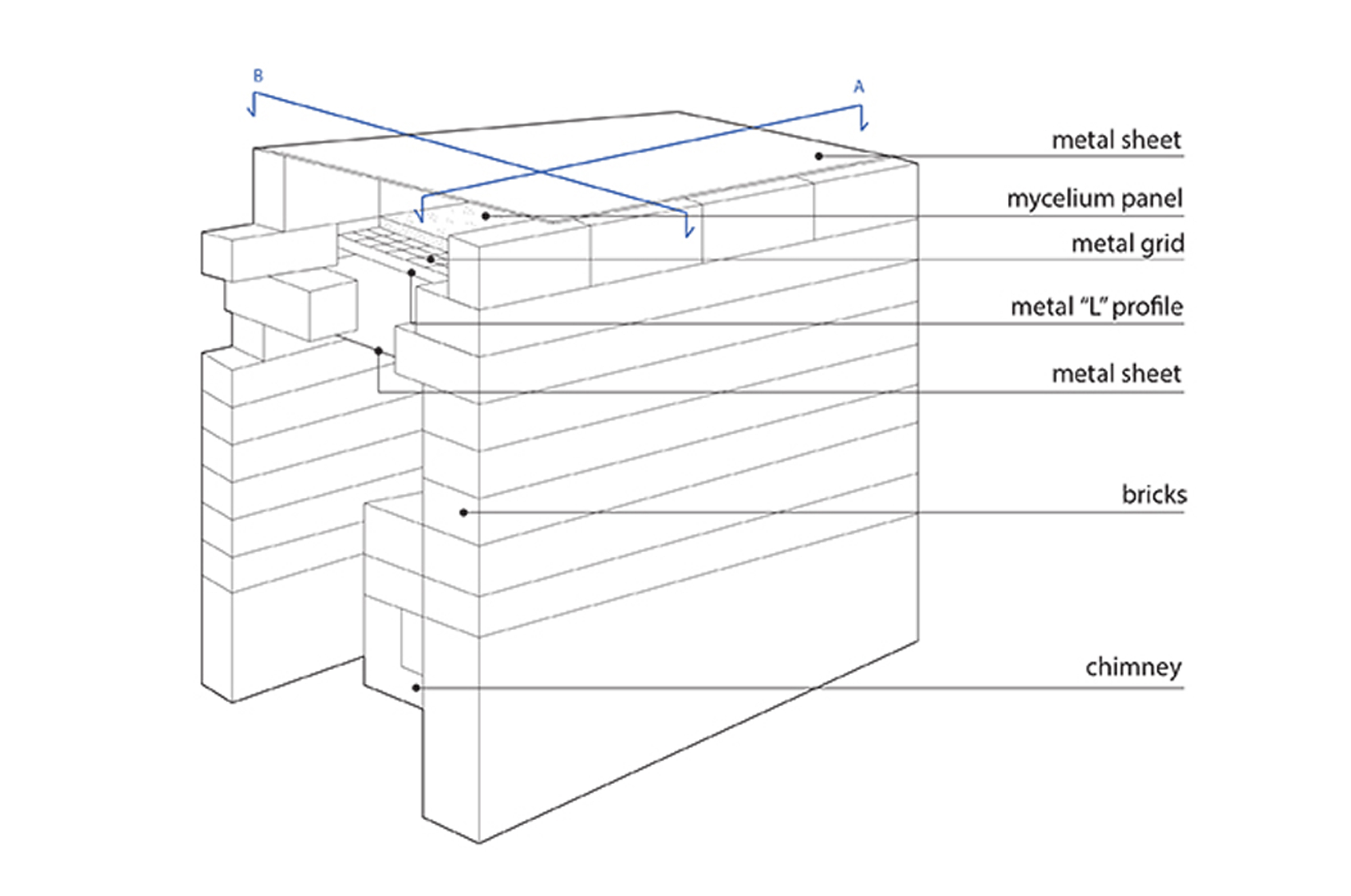

J Rubins wrote:Here’s this about heat treatment for drying by rocket stove in addition to grassroots mycelium insulation production by an organization called Critical Concrete. Lots of cost calculation as well in Euros as they’re based in Portugal. https://criticalconcrete.com/producing-mycelium-insulation/

2

2

J Rubins wrote:Sporeless oyster liquid cultures going for the pretty standard rate which seems surprising. Can’t vouch for the sellers as I haven’t used any of their cultures.

https://millywyco.com/product/sporeless-oyster-liquid-culture/

https://www.mycocultures.com/product/sporeless-oysters-liquid-culture-syringe-pleurotus-ostreatus/

4

4

2

2

7

7

3

3

Anthony Powell wrote:Many years ago I read an article about an English lady growing clothes from fungi. She'd make a plaster cast of her client and make a positive form from that. She'd apply a nutrient gel to that form, and leave it in her damp cellar to grow fluffy. When ready, she'd strip that off the form, and take it down to her local stream (she lived in a hilly area) and leave it in the water for the water life to finish off the loose organic material for a few days. She could then dry it and supply her customer.

More personal insulation means less building insulation needed!

| I agree. Here's the link: http://stoves2.com |