God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Rick Edwards wrote:1. The clay perlite ramps should be kaolin clay? I'm assuming the local clays of a site shouldn't get used for the burn areas or the fire brick unless their properties are investigated.

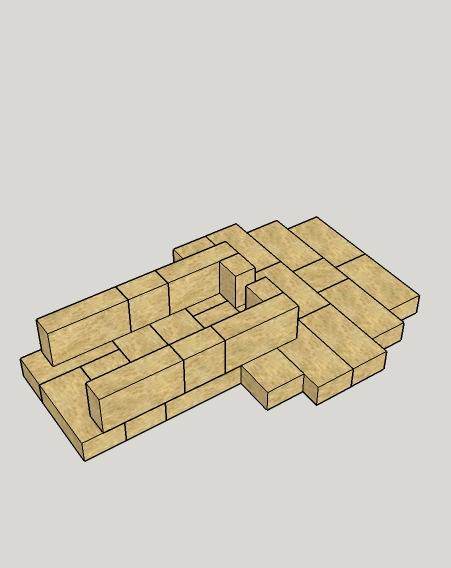

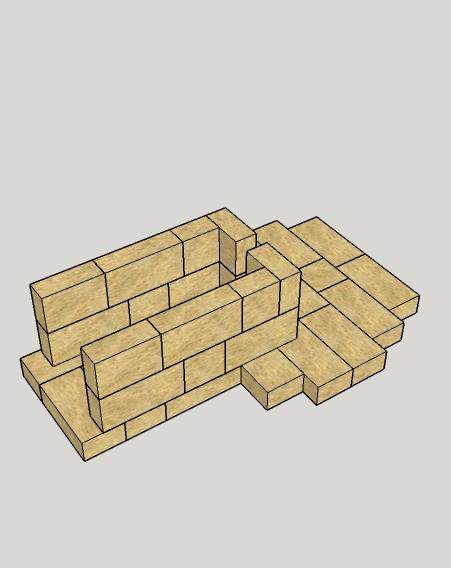

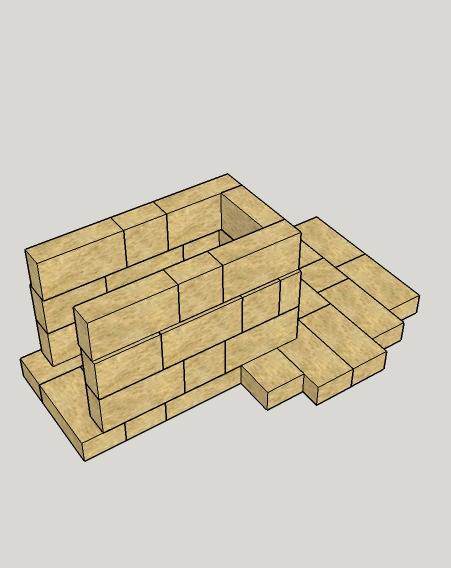

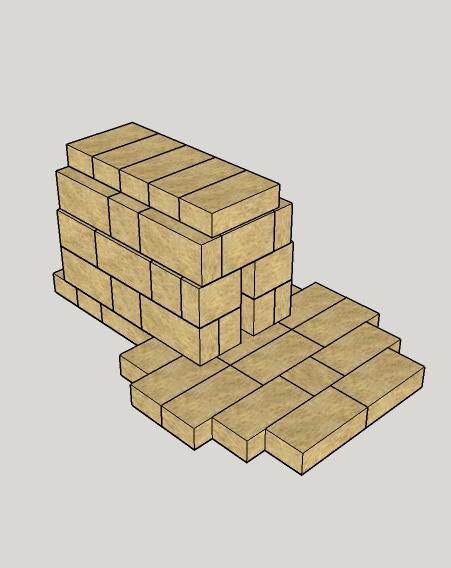

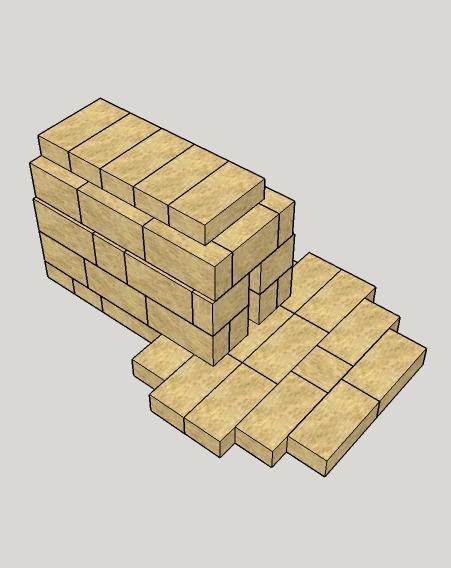

Rick Edwards wrote:2. The riser height dimension came from the formulas and spread sheets on donkey 32. Sounds like that is if optimal materials, yes? The 7 lifts of brick give me only 31.5" from burn chamber floor.

Rick Edwards wrote:3. My P-channel will be 2" x 1" o.d. And the slot gap is 2.3" should I narrow the gap to 2" so air can't go around the sides of the channel?

Rick Edwards wrote:4. Can I offset the barrels from center for better manifold spacing or does this have negative effects on the bell radiation and downdraft qualities.

regards, Peter

Rick Edwards wrote:

4. Can I offset the barrels from center for better manifold spacing or does this have negative effects on the bell radiation and downdraft qualities.

best regards, Byron

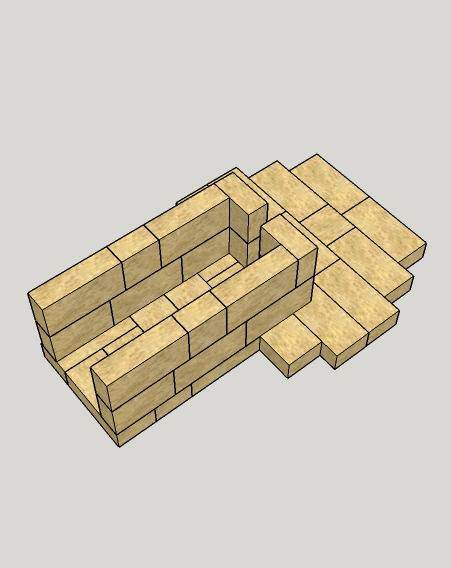

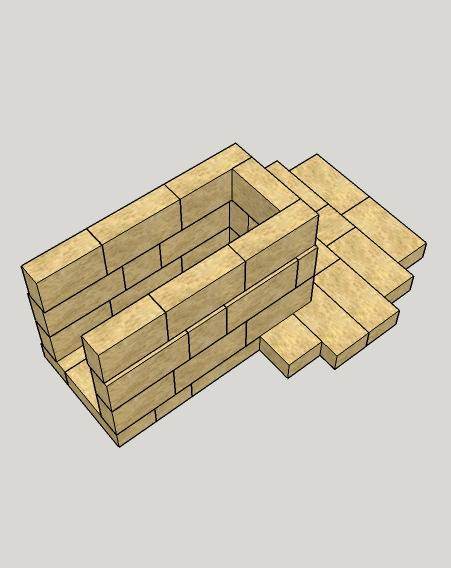

Rick Edwards wrote:The box is going the full 8" longer for more quantity of fuel during each batch burn.

The top is going back to brick instead of duraboard because of extra length of box and Peter's concerns.

Rick Edwards wrote:4. Peter are you saying octagon is preferred over round?

Rick Edwards wrote:6. the split bricks is totally doable and can insulate but with the relax in install date, I want to make this as good as possible for another days work.

Rick Edwards wrote:8. The 2nd barrel (pics) are the sealed type. Tim and Ernie said they preferred them for putting together. Any body know the best way to cut the lid off?

regards, Peter

1

1

Rick Edwards wrote:Since the stove will be fragile slipped firebrick on the outside, we are going to drive T-posts at the front corners so people can't hit it and drop a wall and the burning fuel with it.

regards, Peter

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

regards, Peter

regards, Peter

regards, Peter

1

1

Hans Albert Quistorff, LMT projects on permies Hans Massage Qberry Farm magnet therapy gmail hquistorff

Hans Albert Quistorff, LMT projects on permies Hans Massage Qberry Farm magnet therapy gmail hquistorff

regards, Peter

regards, Peter

regards, Peter

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

Insulating all around the flue would go a long way towards alleviating most of my concern, which is that the giant heat sink of the ground around three sides of the flue is going to keep that flue too cool to work well.

| I agree. Here's the link: http://stoves2.com |