BRK #597

Two developments this Sunday that I find interesting.

First, we moved two cats up to

Cooper Cabin, in preparation for the summer events. Both

Batman AKA

Puff and

Razzberry are now up there.

SEPPer Rio,

SEPPer Roger, and I helped them feel at home, and we even brought up one of the outdoor portable cat houses to give them a place to crash in at night.

Speaking of cats, here's one of the currently-unnamed kitties over at

Allerton Abbey. They all look a lot like their likely dad,

Pearl.

And I've recently graduated from YouTube University...!

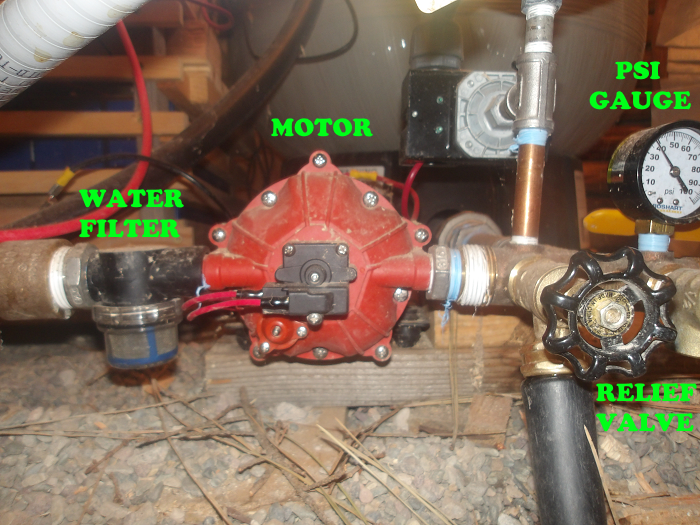

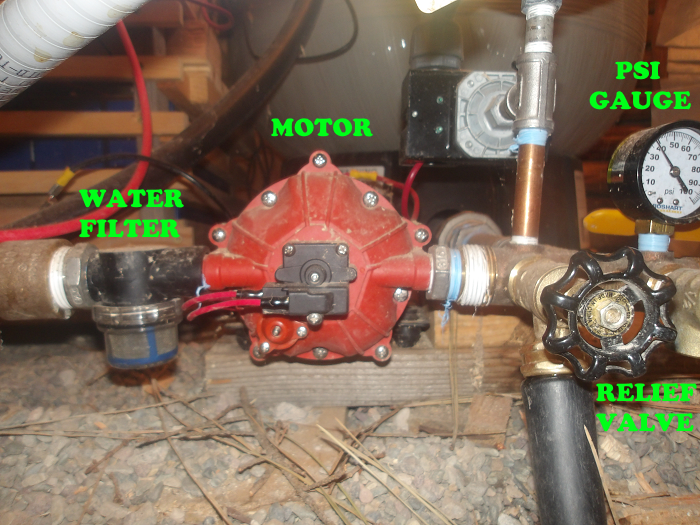

And I've recently graduated from YouTube University...! The pump house up at the

Lab was experiencing a constant-motor-running issue, and I wanted to fix it before the end of the weekend. So after a bit of research (with one video being a step-by-step troubleshooting from a well drilling company), I performed my own checks.

First off, there seemed to be no issue with the air bladder found in the pressure tank. You can check the pressure of your tank with any old conventional tire gauge. Here's the one I used. It reads 48PSI.

That number is right on target.

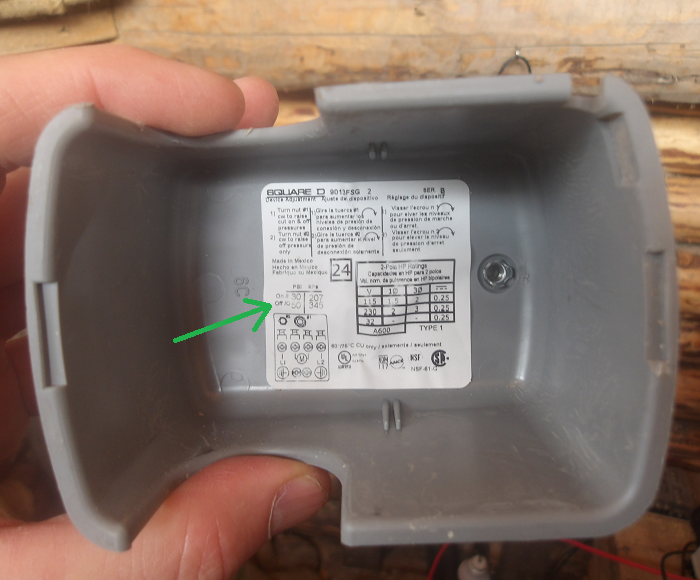

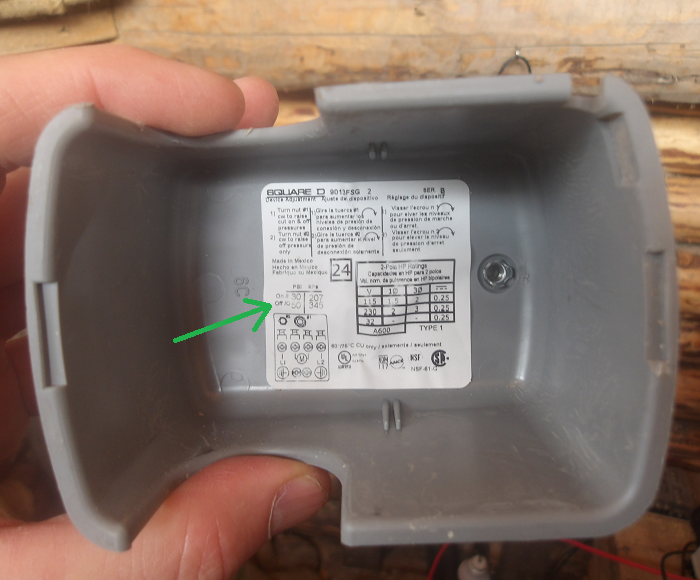

How do I know this? By looking under the cap of the well pump controller. This is like the "thermostat" for the pressurized water in the well system. If pressure is too low, then it "cuts on" or activates the pump. If pressure is too high, then it "cuts out," or shuts it off. Thankfully this

Overton Window (a term I stole from somewhere else, but still applies here) of water pressure is adjustable.

Anyhow, according to the cap of the well pump controller switch, the cut-out number is 50PSI, and my YouTube instructions state that your tank's pressure ought to be 2 to 3PSI lower than the cut-out number. So I referred to the instructions under the cap on how to make adjustments.

There are two adjustable posts with nuts on them. The first adjusts the PSI "window," which is the range between cut-on and cut-out. The second, which is the one I tinkered with, adjusts only the cut-out. By turning the second one counter-clockwise, you reduce the PSI required for the cut-out to occur.

I turned on all the power again, then monitored the cut-out pressure rating. The motor actually cut out, which was great. At that point, I made sure to check that the PSI gauge on the pump motor matched the PSI of the pressure tank. Everything was consistent, so I bled out the tank with a relief valve until the cut-on PSI was reached, then jumped out of my skin as the motor activated and started pumping water. I closed the relief valve, then waited for the cut-off to occur.

Everything is working now, and the rest of the Lab ought to have pressurized hydrants again. Next up will be to address the constant high-pitched beeping noise coming from the solar charge controller. But that's for another day...

That's all for now. Thanks for reading, and enjoy your day...!

5

5

7

7

Thanks for the diligent jamming and canning, Brian and Nan!

Thanks for the diligent jamming and canning, Brian and Nan!

7

7

7

7

9

9