8

8

Burra Maluca wrote:

He treated himself to a wet-saw for cutting the top bricks as they seem to be made of harder stuff than the others. The corners have come out rather well I think!

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

9

9

How permies.com works

What is a Mother Tree ?

7

7

So the obvious question is then... What is the sludge good for? (Other than your dragon that likes to bake, making mud-pies out of?) There must be something creative or permi-ish that could be done with it?Burra Maluca wrote:...I refer to it as the Sludge Making Machine as the water combines with the clay dust to make the most awesome sludge ...

Visit Redhawk's soil series: https://permies.com/wiki/redhawk-soil

How permies.com works: https://permies.com/wiki/34193/permies-works-links-threads

8

8

Jay Angler wrote: So the obvious question is then... What is the sludge good for? (Other than your dragon that likes to bake, making mud-pies out of?)

How permies.com works

What is a Mother Tree ?

3

3

Whoah!! Check out this permie deal!! https://permies.com/w/homesteading-bundle?f=232

"The only thing...more expensive than education is ignorance."~Ben Franklin. "We can easily forgive a child who is afraid of the dark; the real tragedy of life is when men are afraid of the light." ~ Plato

8

8

Carla Burke wrote:Would it work to help seal a pond, I wonder...

How permies.com works

What is a Mother Tree ?

12

12

How permies.com works

What is a Mother Tree ?

13

13

Austin Shackles : email anshackles"at"gmail.com.

14

14

How permies.com works

What is a Mother Tree ?

5

5

'What we do now echoes in eternity.' Marcus Aurelius

How Permies Works Dr. Redhawk's Epic Soil Series

8

8

6

6

Austin Shackles : email anshackles"at"gmail.com.

6

6

Austin Shackles : email anshackles"at"gmail.com.

12

12

How permies.com works

What is a Mother Tree ?

7

7

9

9

Austin Shackles : email anshackles"at"gmail.com.

13

13

8

8

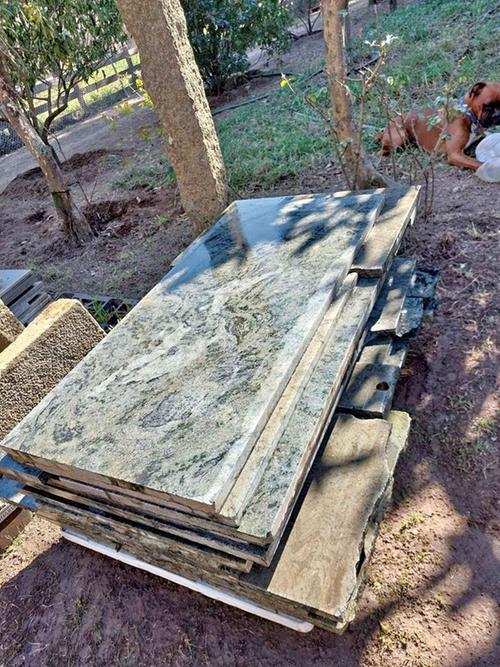

tony uljee wrote:i went to a fireplace surround and mantle making place , local enough to me , i had heard that they bin the off cuts and odds every now and then ---and i asked about and offered to buy a piece of granite approx 24 x 24 " ----165.00 euro---it never made it into my van .

How permies.com works

What is a Mother Tree ?

8

8

Fox James wrote:Well if it is of any encouragement, I would say that 99% of build threads about Rocket mass heaters have a similar post to yours at the same stage!

Austin Shackles : email anshackles"at"gmail.com.

6

6

Austin Shackles wrote:

Next time I'll put about half a load of wood in it, and see how it goes. I'll also give some thought to a chimney preheating device in case I end up needing it. A long handled thingy to put something combustible on which can slide in through the oven and into the base of the chimney might be a plan.

8

8

Used to use that when the previous woodstove wasn't lighting, to pre-heat the air in the top of the stove. For the Walker stove I'm thinking of a small flat shovel on a long handle, on which we can put some oily paper or other readily combustible stuff and slide it in the oven door all the way to the back corner into the base of the chimney. From there the heat will go straight up into the flue pipe.

Used to use that when the previous woodstove wasn't lighting, to pre-heat the air in the top of the stove. For the Walker stove I'm thinking of a small flat shovel on a long handle, on which we can put some oily paper or other readily combustible stuff and slide it in the oven door all the way to the back corner into the base of the chimney. From there the heat will go straight up into the flue pipe.

Austin Shackles : email anshackles"at"gmail.com.

6

6

6

6

Austin Shackles : email anshackles"at"gmail.com.

14

14

Austin Shackles : email anshackles"at"gmail.com.

13

13

How permies.com works

What is a Mother Tree ?

11

11

Austin Shackles : email anshackles"at"gmail.com.

8

8

Visit Redhawk's soil series: https://permies.com/wiki/redhawk-soil

How permies.com works: https://permies.com/wiki/34193/permies-works-links-threads

8

8

11

11

Austin Shackles : email anshackles"at"gmail.com.

8

8

![Filename: chimney-position-outside.jpg

Description: [Thumbnail for chimney-position-outside.jpg]](/t/256489/a/251166/chimney-position-outside.jpg)

![Filename: novaya-papka1.jpg

Description: [Thumbnail for novaya-papka1.jpg]](/t/256489/a/251167/novaya-papka1.jpg)

6

6

![Filename: kak-sdelat-deflektor-volperta-grigorovicha6-1327650053.jpg

Description: [Thumbnail for kak-sdelat-deflektor-volperta-grigorovicha6-1327650053.jpg]](/t/256489/a/251169/kak-sdelat-deflektor-volperta-grigorovicha6-1327650053.jpg)

5

5

Austin Shackles wrote:That's a good thought although the way I built it it's kinda difficult getting the flue apart.

Austin Shackles wrote:hing is, the previous wood burner which was where the stove is now had a single-skin 4" flue which also terminated well below the ridge of the roof. Most days that took a little effort to get going but once the smoke was going upwards it worked well and most of the time had to have a damper in the flue part way shut to prevent it from burning too fast. The new 6" flue for the rocket stove is on the same side of the house about a yard or so away from the old one, so I can't see the climatic conditions overall being a lot different.

Austin Shackles wrote:The other thing is that the stove is still pretty new and may still not be fully dried out: Matt says that it won't burn well until it is and I gather that this applies to most masonry stoves.

I have a couple of options for priming the flue. Most likely, will shut the bypass and have some long handled shovel style thing which can slide into the back corner of the oven space and end up at the bottom of the chimney.

Austin Shackles wrote:follow up: I put some ripped up egg carton on a shovel and slid it under the base of the flue, where it burned rapidly and merrily with the bypass shut. So the flue *does* draw, maybe still will have issues on some days. Lit the stove after that and it was a bit easier and cleaner to get going but still not burning as fast or clean as I expect it to. But there is some progress

9

9

Scott Weinberg wrote:

Austin Shackles wrote:I have a couple of options for priming the flue. Most likely, will shut the bypass and have some long handled shovel style thing which can slide into the back corner of the oven space and end up at the bottom of the chimney.

Correct me if I am wrong, we use to bypass to ASSIST in priming, I am not sure how closing it, no matter where the fire is placed will make it draw better, It should draw its easiest with the bypass open, allowing the most direct to the flue burns. I may have misunderstood your layout, but the primary reason and placement for bypass is to provide a path from your fire to the flue as easy as possible, thus warming the flue and letting things happen quickly and directly.

Scott Weinberg wrote:

Austin Shackles wrote:follow up: I put some ripped up egg carton on a shovel and slid it under the base of the flue, where it burned rapidly and merrily with the bypass shut. So the flue *does* draw, maybe still will have issues on some days. Lit the stove after that and it was a bit easier and cleaner to get going but still not burning as fast or clean as I expect it to. But there is some progress

So with your bypass open, it will burn even quicker/hotter/better? I believe it should.

![Filename: feeding-the-dragon.jpg

Description: [Thumbnail for feeding-the-dragon.jpg]](/t/256489/a/251210/feeding-the-dragon.jpg)

How permies.com works

What is a Mother Tree ?

11

11

Austin Shackles : email anshackles"at"gmail.com.

4

4

Austin Shackles wrote:Probably wasn't clear enough, so here are a couple of

thousand wordspictures. The top one is a section through the side of the stove. The normal flue outlet is at the bottom rear of the oven, the gas having gone all around the stove. The Bypass is at the top between the back of the firebox and the flue space right under where the metal chimney attaches and can be opened and closed. Open bypass is to aid lighting the stove, closed to make the heat circulate as it should, except that so far it makes smoke come out places I don't want. The bypass is designed so it can left partly open if desired for better draft at a cost in overall performance.

The second picture is an isometric (approximately) sketch of the stove showing the location of the brick flue and where the priming fire was at the bottom of the flue. By shutting the bypass, as Burra already said, any smoke from that priming fire can only go up the chimney, not decide to feed back into the firebox.

The normal operation when it's working right has the heat path going across under the stove top to the left side, then down the side of the stove to the bottom where the oven space and the outlets to the bench are, and ending up at the base of the brick flue

Today I got high temperature silicon and sealed around the edge of the stove top. It might not be high enough temperature, so I also got some really high temperature stuff in case I have to redo it. The really high temperature stuff goes to 1500°C but it sets rigid, while the silicon stays a bit flexible. With a rigid fit it might be the stove top can expand and crack the top brickwork.

6

6

Scott Weinberg wrote:But rather, in your sketch, I don't see any port location/expansion area, drawn in? maybe this type doesn't warrant this area?

And is the port sized to the fire box (batch) size

And lastly is your batch box (if it is called that) sized to your flue size?

How permies.com works

What is a Mother Tree ?

3

3

14

14

How permies.com works

What is a Mother Tree ?

14

14

Austin Shackles : email anshackles"at"gmail.com.

10

10

|

Oh sure, it's a tiny ad, but under the right circumstances, it gets bigger.

Our PIE page has been updated, anybody wanna test?

https://permies.com/t/369340/PIE-page-updated-wanna-test

|