6

6

Harry: I can't believe we drove around all day and there's not a single job in this town. There is nothing, nada, zip!

Lloyd: Yeah, unless you wanna work 40 hours a week!

1

1

Harry: I can't believe we drove around all day and there's not a single job in this town. There is nothing, nada, zip!

Lloyd: Yeah, unless you wanna work 40 hours a week!

1

1

Harry: I can't believe we drove around all day and there's not a single job in this town. There is nothing, nada, zip!

Lloyd: Yeah, unless you wanna work 40 hours a week!

1

1

Harry: I can't believe we drove around all day and there's not a single job in this town. There is nothing, nada, zip!

Lloyd: Yeah, unless you wanna work 40 hours a week!

2

2

Harry: I can't believe we drove around all day and there's not a single job in this town. There is nothing, nada, zip!

Lloyd: Yeah, unless you wanna work 40 hours a week!

1

1

Brian Ham wrote:You might be interested in the ideas this engineer uses to assemble a full-sized Stonehenge replica using only a single human power. It's all about balance... http://youtu.be/lRRDzFROMx0

projects blog http://thekulaproject.tumblr.com

My Signature for the last few years was "just spinning wheels," but after our PDC at Pauls Place this summer I feel like we are finally catching traction. Hope to be threading some more. got a roof on our house, swales dug, and finally starting to work on our plan in more details.

Harry: I can't believe we drove around all day and there's not a single job in this town. There is nothing, nada, zip!

Lloyd: Yeah, unless you wanna work 40 hours a week!

My Signature for the last few years was "just spinning wheels," but after our PDC at Pauls Place this summer I feel like we are finally catching traction. Hope to be threading some more. got a roof on our house, swales dug, and finally starting to work on our plan in more details.

Scott H.

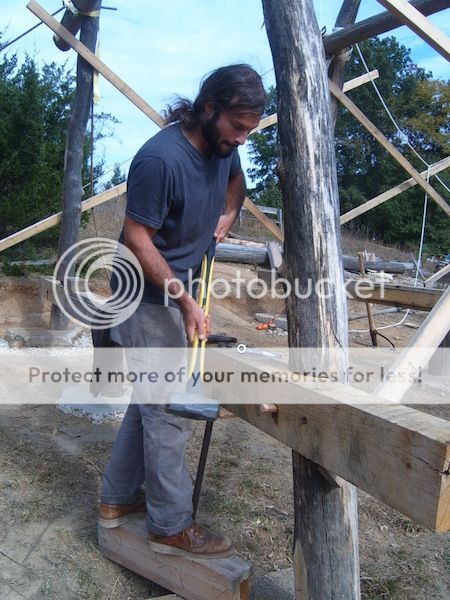

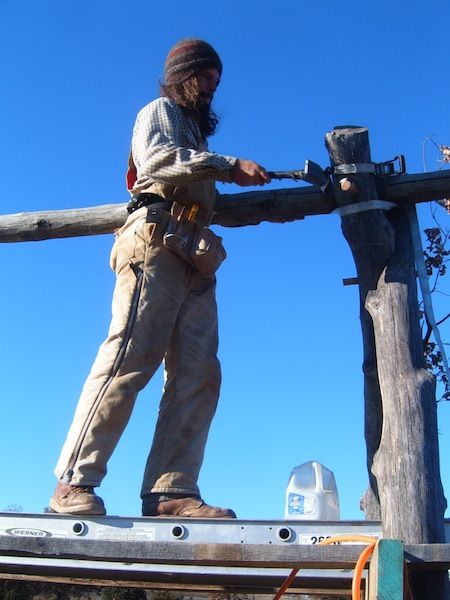

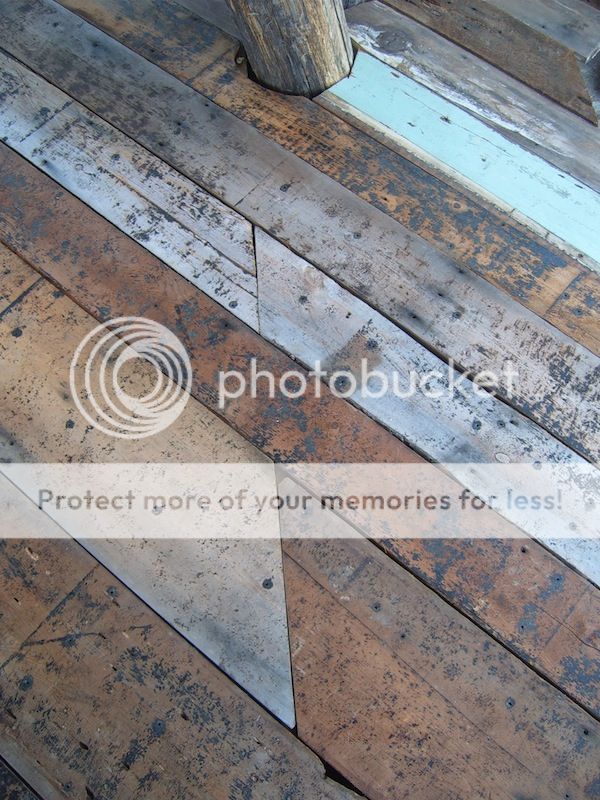

Check out my house project!

Harry: I can't believe we drove around all day and there's not a single job in this town. There is nothing, nada, zip!

Lloyd: Yeah, unless you wanna work 40 hours a week!

3

3

Harry: I can't believe we drove around all day and there's not a single job in this town. There is nothing, nada, zip!

Lloyd: Yeah, unless you wanna work 40 hours a week!

Check out ourwebsite of herbal goodness!

Harry: I can't believe we drove around all day and there's not a single job in this town. There is nothing, nada, zip!

Lloyd: Yeah, unless you wanna work 40 hours a week!

1

1

My Signature for the last few years was "just spinning wheels," but after our PDC at Pauls Place this summer I feel like we are finally catching traction. Hope to be threading some more. got a roof on our house, swales dug, and finally starting to work on our plan in more details.

1

1

Harry: I can't believe we drove around all day and there's not a single job in this town. There is nothing, nada, zip!

Lloyd: Yeah, unless you wanna work 40 hours a week!

thanks for posting beautiful work and congrats on the baby!

thanks for posting beautiful work and congrats on the baby!

| I agree. Here's the link: http://stoves2.com |