3

3

Children, Rabbits, Chickens, Bees

I certify this for 1 point

3

3

You are welcome to check out my blog at http://www.theartisthomestead.com or my artwork at http://www.davidhuang.org

Mike Haasl approved this submission.

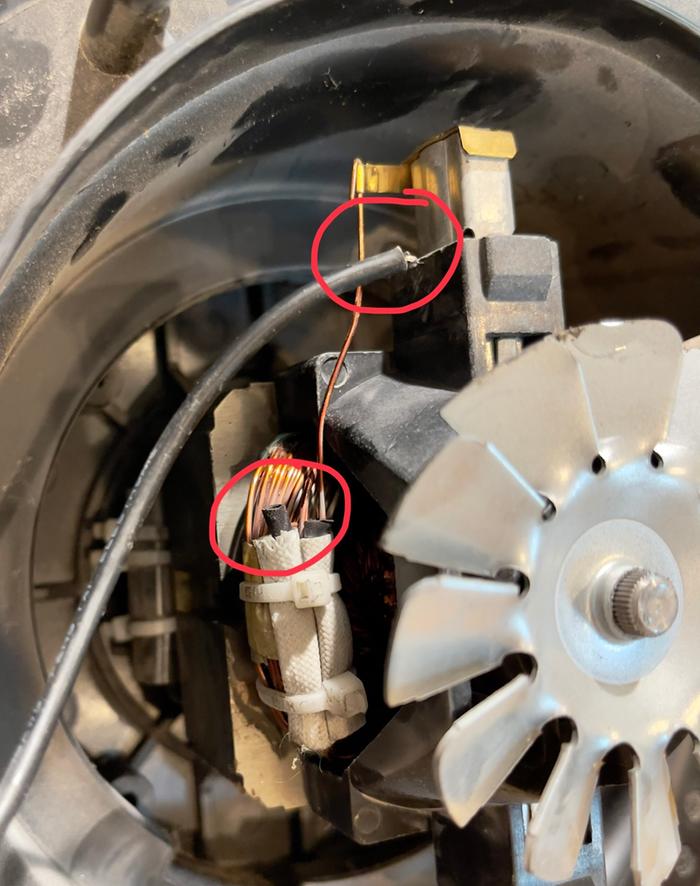

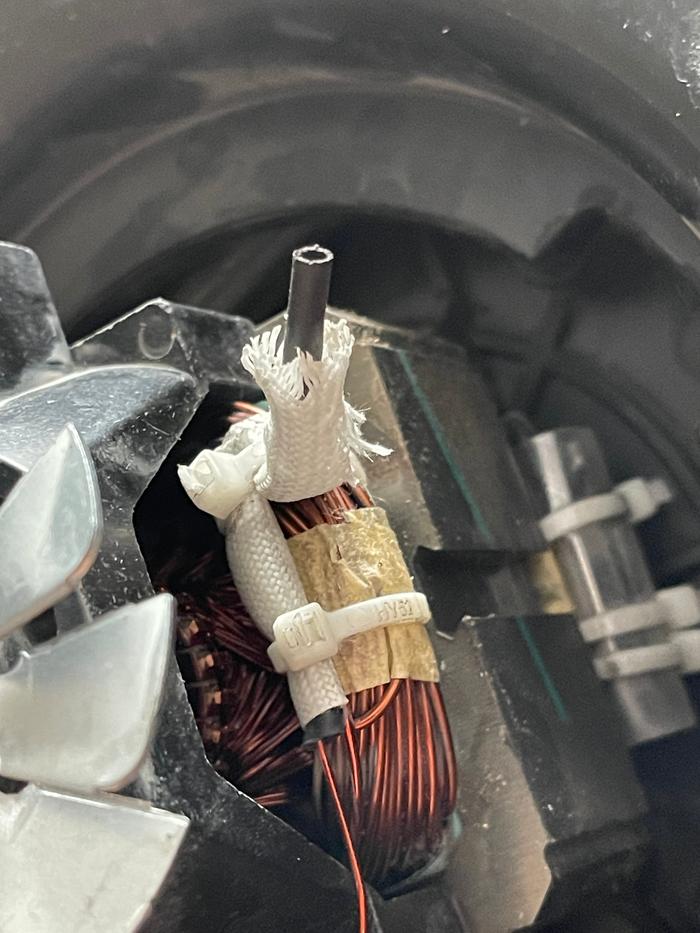

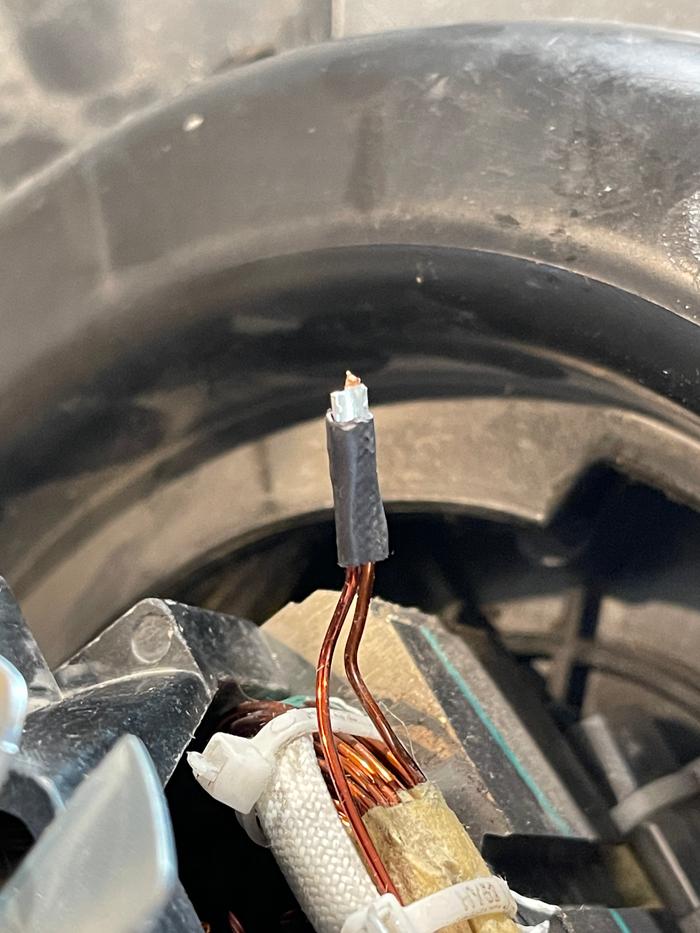

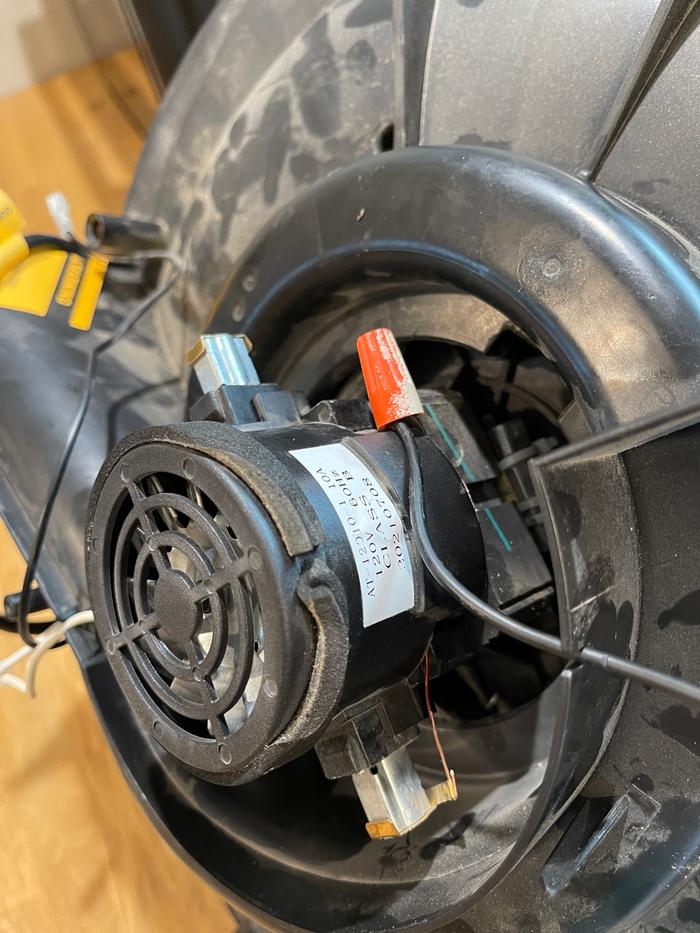

Two points. One for the actual work plus one for using good troubleshooting techniques & explaining the process so well. Good job!

Side note... when replacing fans like that I strongly recommend spending an extra dollar or two for fans with bearings. They are much more reliable & longer lasting. Not sure which those are, just throwing it out there for general FYI to help anyone who might be in a similar situation.

2

2

He whai take kore noa anō te kupu mēnā mā nga mahi a te tangata ia e kōrero / His words are nothing if his works say otherwise

Mike Haasl approved this submission.

Note: Triangular screws, what a great idea  Good job!

Good job!

2

2

Cargo bikes are cool

David Huang approved this submission.

Note: I hearby certify this complete and worth 1 point.

1

1

David Huang approved this submission.

Note: I certify this complete for 1/2 point. Nice that it ended up being an easy fix!

Children, Rabbits, Chickens, Bees

|

It used to be a lot bigger, but now it is a rather tiny ad:

GAMCOD 2025: 200 square feet; Zero degrees F or colder; calories cheap and easy

https://permies.com/wiki/270034/GAMCOD-square-feet-degrees-colder

|