5

5

You are welcome to check out my blog at http://www.theartisthomestead.com or my artwork at http://www.davidhuang.org

Mike Barkley approved this submission.

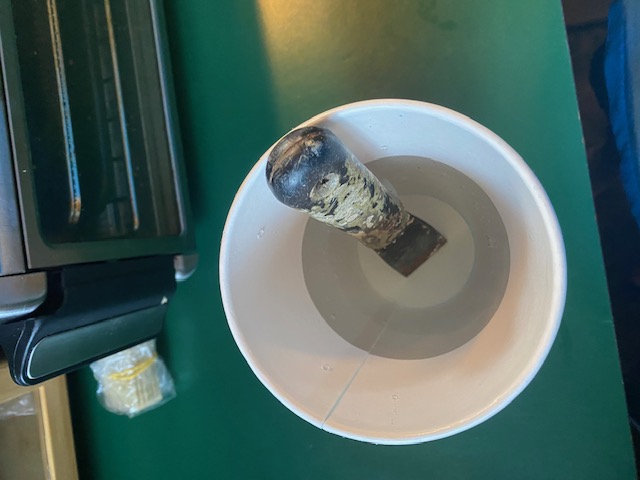

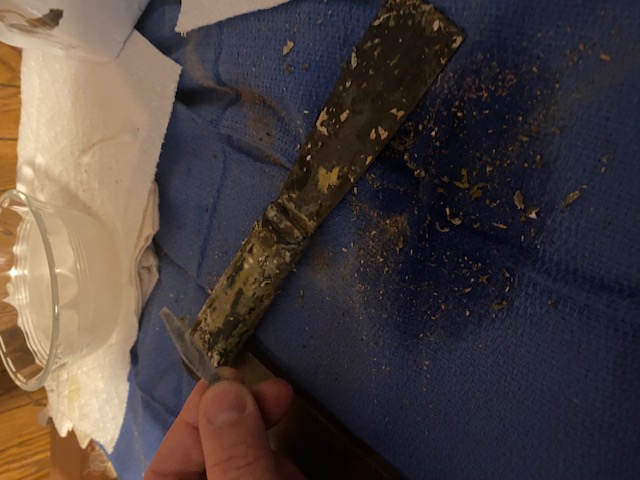

klara stinders wrote:Cleaned this lovely old traditional belgian tool with vinegar and an inox sponge

Gave it a vinegar bath for a total of around 3 hours, without having the handle in the vinegar.

To get closer to the handle, I wrapped an in vinegar soaked cloth around the blade so it would also get the vinegar treatment.

I had no patience, so every now and again I went to do some scrubbing, but everytime I found out I was too early.

After those 3 hours, I was happy with the end result. Dried it with a paper towel, let it sit in the air for a while, and then oiled it with linseed oil.

Can't wait for this baby to be sharpened :-)

2

2

"Despise not the day of small things."

2

2

- Tim's Homestead Journal - Purchase a copy of Building a Better World in Your Backyard - Purchase 6 Decks of Permaculture Cards -

- Purchase 12x Decks of Permaculture Cards - Purchase a copy of the SKIP Book - Purchase 12x copies of Building a Better World in your Backyard

Someone approved this submission.

There is madness to my method.

"Life finds a way"- Ian Malcolm

"We're all mad here" - The Cheshire Cat

Someone approved this submission.

Note: I certify this badge bit complete.

2

2

"The winter will ask what we did all summer" - Henry David Thoreau

Paul Fookes approved this submission.

Note: I certify this BB complete. Well done

1

1

"[6] Let the people, O God, confess to Thee: let all the people give praise to Thee: [7] The earth hath yielded her fruit. May God, our God bless us, [8] May God bless us: and all the ends of the earth fear Him." (Psalms 66/67)

Someone approved this submission.

Note: Nicely Done

|

I found a beautiful pie. And a tiny ad:

The new kickstarter is now live!

https://www.kickstarter.com/projects/paulwheaton/garden-cards

|