1

1

2

2

Small-holding, coppice and grassland management on a 16-acre site.

Mike Barkley flagged this submission as an edge case BB.

BBV price: 0

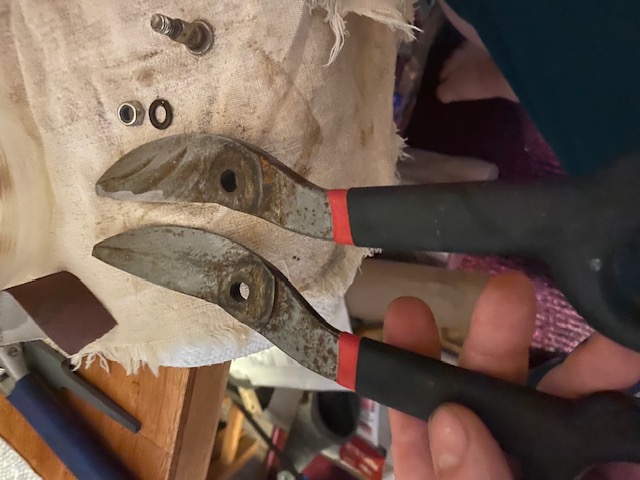

Note: please include a pic of the worn fastener for further consideration

Mike Barkley approved this submission.

Small-holding, coppice and grassland management on a 16-acre site.

1

1

Small-holding, coppice and grassland management on a 16-acre site.

Paul Fookes approved this submission.

Note: I certify this BB complete. These scissors have a drop pressed pin which cannot be removed, so cannot be disassembled. Well done Timothy.

You are welcome to check out my blog at http://www.theartisthomestead.com or my artwork at http://www.davidhuang.org

- Tim's Homestead Journal - Purchase a copy of Building a Better World in Your Backyard - Purchase 6 Decks of Permaculture Cards -

- Purchase 12x Decks of Permaculture Cards - Purchase a copy of the SKIP Book - Purchase 12x copies of Building a Better World in your Backyard

Someone approved this submission.

He whai take kore noa anō te kupu mēnā mā nga mahi a te tangata ia e kōrero / His words are nothing if his works say otherwise

Someone approved this submission.

Paul Fookes approved this submission.

Note: I certify this BB complete. Well done

"The winter will ask what we did all summer" - Henry David Thoreau

Someone flagged this submission as an edge case.

BBV price: 0

Note: No oil used, but being kitchen scissors and stainless they dont need it I guess

|

I found this tiny ad in my shoe

Looking for cold-climate growers to join a GOOF livestream panel (Missoula)

https://permies.com/t/369111/cold-climate-growers-join-GOOF

|